Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

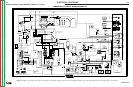

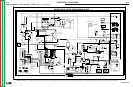

ELECTRICAL DIAGRAMS

RANGER 305D

SCHEMATIC - ENTIRE MACHINE - CODE 11121 (L12212) PAGE 1 OF 2

EN -168

S

O

L

ID

E

D

G

E

L12212

RANGER 305D

MACHINE SCHEMATIC

NONE

L11946

DEO

BAM

-

UNLESS OTHERW ISE SPEC IF IED TOLERAN CE

MANUFAC TURIN G TOLERANCE PER E205 6

ON 2 PLAC E DECIMA LS IS ± .02

ON 3 PLACE DECIMALS IS ± .002

ON ALL ANG LES IS ± .5 OF A DEGREE

WITH PUB LISHED S TANDARDS.

MA TERIA L TOL ERANCE (" ") TO AGREE

t

DO NOT SCALE THIS DRAWING

DRAWN BY:

DESIGN INFORMATION

ENGINEER:

APPRO VED:

REFERENCE:

EQUIPMENT TYPE:

SUBJECT:

SCALE:

MATERIAL

DISPOSITION:

APPROVAL

DATE:

PROJECT

NUMBER:

UF

CRM35573

1

PA GE ___ O F ___

2

ENGINEERING CONTROLLED

MANUFACTURER:

No

DOCUMENT

NUMBER:

DOCUMENT

REVISION:

THIS D O CUME NT C O NTAINS PR OP RIETARY INF ORMATION OW NE D BY LINC OLN GLOBAL, INC. A ND MAY N OT BE D UPLICATE D, COMMU NICATE D

TO OT HE R PARTIES O R USE D FO R ANY PU RP OSE WIT HOUT T HE EX PRESS W RITTE N PE RMISSION OF LIN COLN GLOBAL, INC.

PROPRIETARY & CONFIDENTIAL:

A

12/11/2003

RELEASED "A.02" FROM "X"

CHANGE DETAIL:

L12212

W3

W2

D1 - THREE PHASE BRIDGE RECTIFIER

D

3

C3

800uf

150vdc

7

201

5H

200

200A

W1

C

E

L1 CHOKE

CHOPPER PC BOARD

GATE SIGNAL

ARC VOLTAGE FEEDBACK SIGNAL

3

5

6

GND E

120 V AC

240 V AC

120 V AC

TO AUX.

OUTLETS

AND

AMPHENOLS

(VIA CIRCUIT

BREAKERS)

42 VOLT AC

WIRE FEEDER

POWER

41

42

9

TWO POLE 3600 RPM ALTERNATOR

DC BUS VOLTAGE

90+/-10VDC @ HI IDLE

R1

OUTPUT

CONTROL 10K

77 (J7-1)

76 (J7-4)

75 (J7-5)

R2

ARC

CONTROL 10K

279 (J7-6)

278 (J7-7)

277 (J7-8)

(J3-14) 252

(J3-7) 251

IDLER SWITCH

(J1-4) 2

(J1-3) 4

WELD TERM. SW.

MODE

SWITCH

CC

CV

PIPE

TIG

(J7-9) 214

(J7-14) 218

(J7-15) 220

(J7-16) 222

260A (J3-4)

261A (J3-3)

TOROID-

SENSES AC

POWER TO

ACTIVATE

IDLER

WELD CONTROL

PC BOARD

42 VOLT AC

POWER FOR

ROTOR FIELD CIRCUIT

12 VOLT

BATTERY

(J2-7) 210B

(J2-5) 215

(J2-4) 404

(J2-1) 200N

ELECTRIC

FUEL

PUMP

OILPRESSURE

SWITCH

(CLOSES ON

LOW OIL

PRESSURE)

HOUR METER

(J2-9) 224B

GLOWPLUG

SWITCH S7

RUN-STOP SWITCH

(SHOWN IN RUN)

15A BATTERY

CIRCUIT BREAKER

209

212

204S (J6-1)

206S (J6-2)

208B (J3-15)

23 (J3-10)

25 (J3-9)

5K (J2-3)

FRAME

GROUND

REMOTE

CONTROL 10K

77A (J1-11)

76A (J1-14)

75A (J1-10)

SH UNT

50MV= 400 AMPS

206S

204S

WELD CURRENT

FEED BACK SIGNAL

POSITIVE

OUTPUT

TERMINAL

NEGATIVE

OUTPUT

TERMINAL

BY-PASS

PC BOARD

208C

208

21

WIREFEEDER

VOLTMETER

POLARITY

SWITCH

206A

208A

STARTER

SOLENOID

STARTER

MOTOR

224

210

+

SLIP RINGS

50 V DC

+

+

10 V

0-10 V

0 V

10 V

-15 V (W/O POT.)

0 V

0 V

15 V

15 V

0 V

IGBT (8)

TWISTED

PAIR

(TO AMPHENOL)

(TO AMPHENOL)

2A

4A

(TO AMPHENOL)

206C

206B

31

32

41A

A

B

C

D

E

F

77A

21

42A

75A

GND-A

4A

2A

76A

77B

76B

75B

REMOTE

GROUND

AMPHENOL

CONTROL

INPUT TO

AMPHENOL

115VAC

CONTACTOR

WORK

REMOTE

CONTROL

42VAC

GROUND

AMPHENOL

J

A

D

C

H

B

K

E

F

G

I

77B

76B

75B

GND-B

4B

2B

4B

2B

+12 to 14V @ RUN (INPUT)

B7

B8

B6

B3

B5

B2

B4

B1

+COM

-INPUT

-OUTPUT

+12 to 14V @ NORMAL OIL PRES. (INPUT)

R3 25 OHM

13 (J3-8)

14 (J3-16)

(J1-7) 305

(J1-12) 305

305 I.D. JUMPER (Part

of amphenol plug and

lead assembly.)

ALTERNATOR

IGN

L

BAT

FUEL

SOLENOID

PULL

HOLD

BLACK

WHITE

RED

START BUTTON

SWITCH S2

GLOWPLUGS

YELLOW

ENGINE

PROTECTION

LIGHT

CR1

9

B

A

3

COOLANT

TEMPERATURE

SWITCH

(CLOSES ON HIGH

TEMPERATURE

ABOVE 230F)

IDLE

SOLENOID

PULL

HOLD

BLACK

WHITE

RED

404 (J43-8)

PULL COIL

PC BOARD

B2

B1

B4

+15V @ LOW IDLE TO PULL COIL BOARD

LOW IDLE SOLENOID HOLD COIL (0V @ LOW IDLE)

60 TO 65 VAC PHASE TO PHASE

BETWEEN W1, W2 AND W3

AT HIGH IDLE

210

210

229

225

223

211

209

209

231

215

232

D4

TWISTED

PAIR

REVOLVING FIELD

FIELD RESISTANCE

APPROX. 5 OHMS @ 75F

ENGINE

PROTECTION

RELAY

GLOWPLUG SWITCH ENERGIZES

ELECTRIC FUEL PUMP AND FUEL

SOLENOID HOLD COIL THRU D4. IT

ALSO FUNCTIONS AS AN ENGINE

PROTECTION BYPASS UNTIL OIL

PRESSURE BUILDS UP.

IF COOLANT TEMP SWITCH OR OIL PRESSURE SWITCH

CLOSE, CR1 ENERGIZES OPENING CONTACTS AND

SHUTTING OFF FUEL SOLENOID TO STOP ENGINE.

FUEL SOLENOID PULL

COIL IS ENERGIZED BY

STARTER SOLENOID.

TWISTED

PAIR

FLYBACK

DIODES (6)

FILTER

CAPACITORS (4)

+

IGBT'S, FLYBACK DIODES AND

FILTER CAPACITORS ARE INTEGRAL

TOCHOPPER MODULE AND NOT

INDIVIDUALLY REPLACEABLE.

ROTOR FLASHING

R4

50 OHM

100 W

10,000uF x4

Shunt onback of positive

output terminal

Choke is beneath bearing end

of generator on support.

Rectifier mounted to generator support

above output choke.

Located on front of fan

baffle near top of

machine.

R3 located on front of fan baffle

on left side near bottom of

machine

R4 islocated on front of

fan baffle near top of

machine

C3 and D3 located onrear of fan baffle

on left side of machine.

Relay CR1 and D4 located on fron

baffle on right side of machine.

Located next to

control board.

P/N G4107-1

Located on wiring behind

receptacles.

Open Circuit Volts:

CC

Max

Min

58 58

58

58

58

26

12

12

CV

Pipe

Tig

Located on back of

output panel

between terminals

Control board common is

at welder positive output

and shunt

Control board circuits associated with J2 are part

of engine electrical system and are common to

frame ground (negative battery terminal.

Rotor Flashing: +12 volts

@ 0.5 amps

until generator builds up

then +50 volts @ 0 amps.

Swich closed for high

idle.

Battery voltage:

12.6 volts at rest

14 volts engine

running

PL

1

P/N

L11768-1

TIMER

CIRCUIT

+15V @ LOW

IDLE

FUEL

SOLENOID

AND FUEL

PUMP

ENERGIZED

FOR RUN

S1

0.2 OHM

11 OHMS

0.2 OHM

11 OHMS

WELD AMMETER

WELD VOLTMETER

(J4-1 to 10) (J5-1 to 10)

Meters display setpoint volts or amps when not welding.

Meters display actual volts and amps when welding.

Hold function displays actual volts and ampsfor

approximately 5 seconds after welding stops.

During this hold display the right most decimal point will

blink.

Power Supply

to Control

Board

PWM Signal to Chopper

15 volt @ 20 kHz

p/n

L11845-1

FUEL SENDER

2 TURNS

THRU

FERRITE

L4

2 TURNS THRU FERRITE

L3

2 TURNS

THRU FERRITE

L5

2 TURNS

THRU

FERRITE

2 TURNS THRU

FERRITE

L2

L6

240-265 OHMS EMPTY

20-35 OHMS FULL

FUEL

GAUGE

1

4

L8 L7

J73-3

P73-3

J74

P74

P74

J74

P73-2

J73-2

J73-4

P73-4

J72-3

P72-3

P72-4

J72-4 J72-2

P72-2

Control Board senses Weld Output

from Current Feedback Shunt

to activate idler.

Chopper is mounted on the back side of fan

baffle near top of machine. Requires added

baffle for cooling air flow.

All leads

1 time thru

ferrite

All leads

1 time thru

ferrite

IDLE SOLENOID

ENERGIZED FOR

LOW IDLE

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.

G-13 G-13