Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

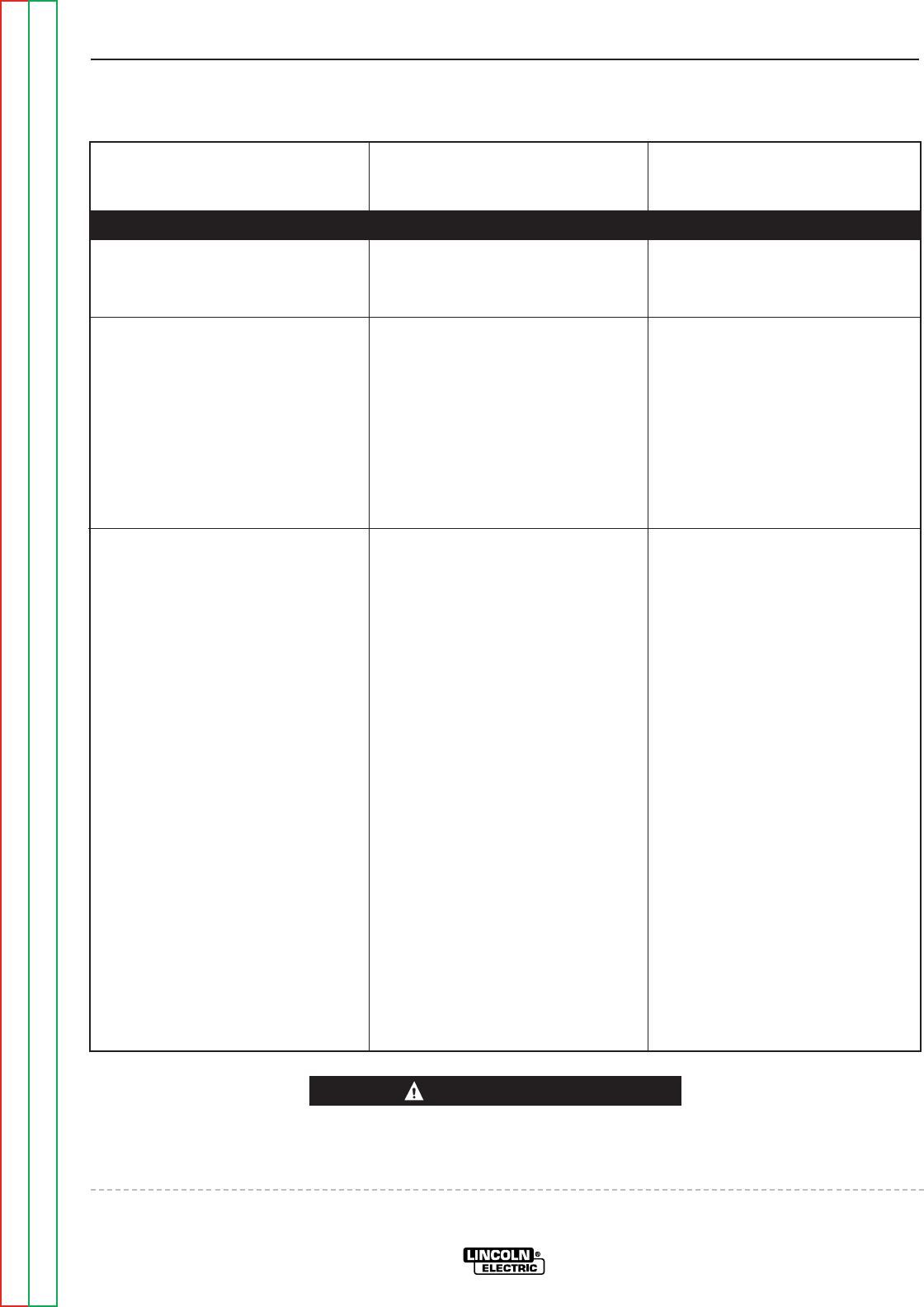

TROUBLESHOOTING & REPAIR

F-4 F-4

RANGER 305D

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely,

contact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

1-888-935-3877.

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENT(S)

RECOMMENDED

COURSE OF ACTION

POWER OUTPUT PROBLEMS

Major mechanical or electrical

damage is evident.

1. Contact your local Lincoln

Authorized Field Service

Facility.

1. Contact the Lincoln Electric

Service Department at 1-888-

935-3877.

No welding output or auxiliary

power. The engine operates nor-

mally.

1. Check for loose or faulty con-

nections at any leads, cables or

cords attached to either the aux-

iliary output receptacles and/or

the weld output terminals.

1. Check the brushes for wear and

proper contact to the rotor slip

rings.

2. Perform the Brush and Slip

Ring Service procedure.

3. Perform the Rotor Voltage Test.

4. Perform the Stator Voltage

Test.

CAUTION

Observe Safety Guidelines

detailed in the beginning of this manual.

TROUBLESHOOTING GUIDE

No welding output in any mode.

The auxiliary output is normal. The

engine operates normally.

1. Place the Welding Terminals

switch in the “WELD TERMI-

NALS ON” position. If the prob-

lem is solved, the fault may be in

the external control cable, or the

attached wire feeder, amptrol,

arc start switch, etc. (if used)

2. With the engine at high idle

(3650RPM), the machine in the

CC-STICK mode, the output

control at maximum, and the

welding terminals switch in the

“WELD TERMINALS ON” posi-

tion; check for the presence of

approximately 58VDC, OCV

(open circuit voltage) at the weld

output terminals.

3. If the correct OCV is present at

the welding output terminals,

check the welding

cables,connectors, work

clamps, electrode holder, etc. for

loose or faulty connections.

1. Check for damaged conductors

or faulty connections on the

heavy current carrying leads

that connect the output studs to

the Chopper module and to the

output Rectifier. Also Check

the shunt and choke assem-

blies for damage and faulty

connections.

2. Perform the Chopper Module

Function Test.