Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-26 F-26

RANGER 305D

FUEL SHUTDOWN SOLENOID TEST (continued)

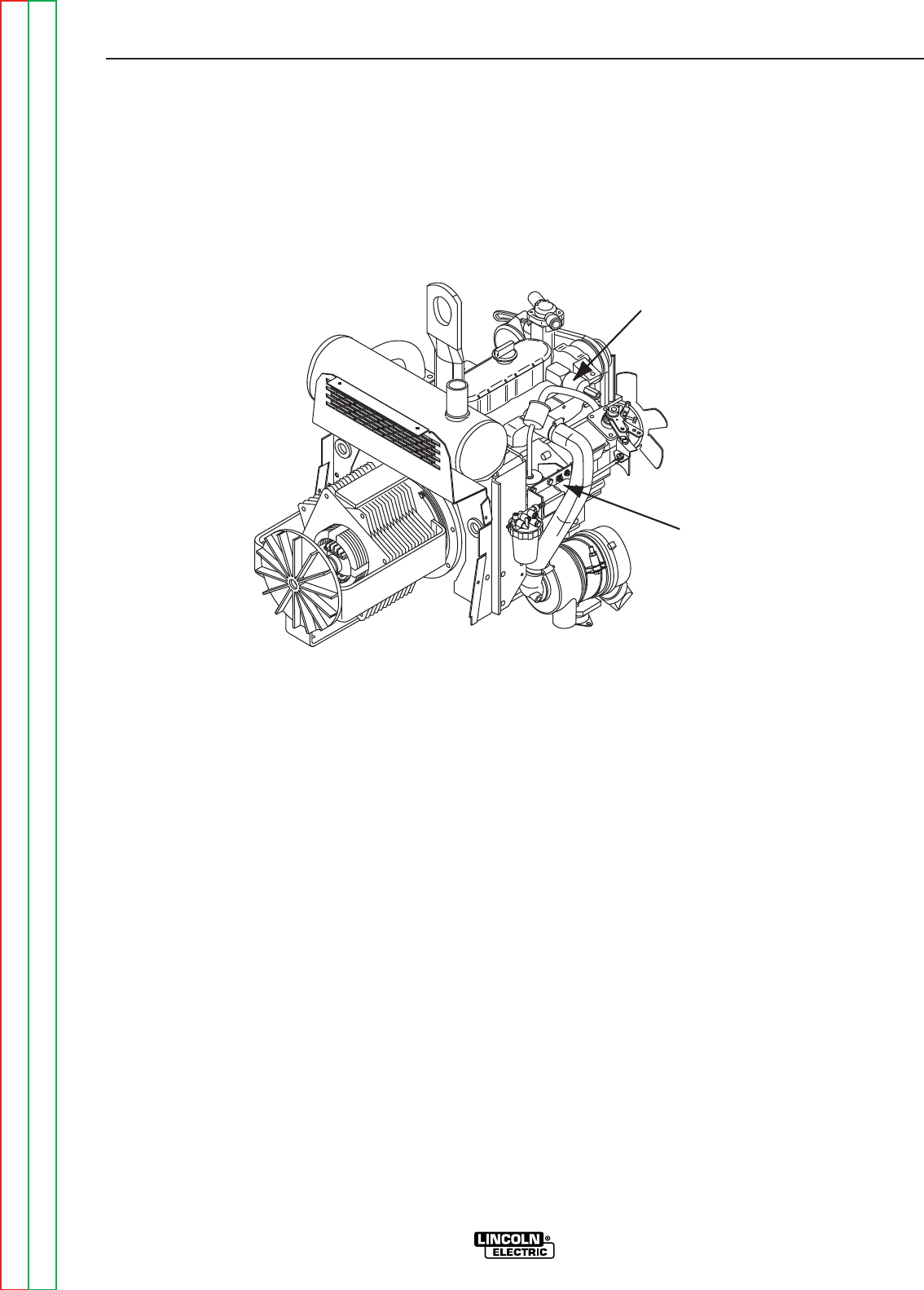

FIGURE F.3 – FUEL SHUTDOWN SOLENOID LOCATION

TEST PROCEDURE

1. Turn the engine off.

2. Open the right side engine service access

door.

3. Locate the fuel solenoid, located on top of

the engine.

4. Locate and unplug harness connection P/J

73. Cut any necessary cable ties. See

Figure F.4. See Wiring Diagram.

5. Using the Ohmmeter, check the pull-in coil

resistance, (black wire to white wire). The

normal resistance is less than 0.5 ohms.

Check the hold-in coil resistance, (black

wire to red wire). The normal resistance is

approximately 11 ohms. Check the

Resistance between the black wire and a

clean, unpainted chassis ground. The

resistance should be very high, 500,000

Ohms or more. If any of the above resis-

tance values are incorrect, the solenoid

may be faulty. Replace.

6. Using an external 12VDC supply, apply

voltage to the pull-in coil leads, (black-) to

(white+). The solenoid should activate.

REMOVE THE VOLTAGE immediately to

avoid damaging the solenoid.

Apply 12VDC to the hold coil, leads,

(black-) to (red+) While the voltage is

applied, manually move the solenoid to

the fuel on position. The solenoid plunger

should hold this position until the voltage

is removed.

If either coil does not operate as

described, check for mechanical restric-

tions or other problems with the linkage.

If the linkage is intact and the solenoid

does not operate correctly when 12VDC

is applied, the solenoid may be defective.

Replace.

Re-connect fuel solenoid and replace any

previously removed cable ties.

7. If finished testing, close the engine ser-

vice access doors.

IDLEIDLE

SOLENOIDSOLENOID

SHUTDOWNSHUTDOWN

SOLENOIDSOLENOID