Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-44 F-44

RANGER 305D

ROTOR VOLTAGE TEST (continued)

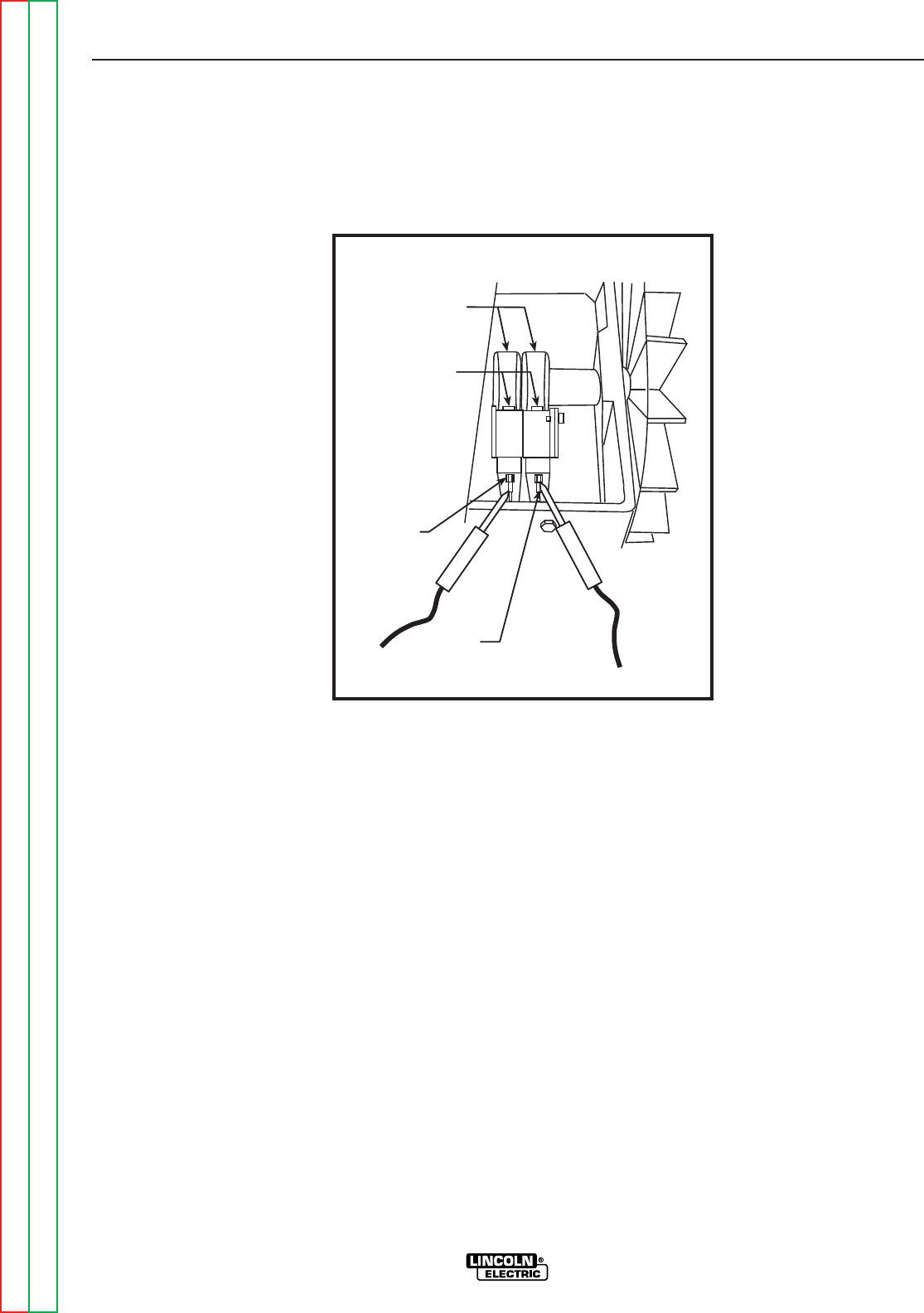

FIGURE F.10 – LEAD LOCATIONS

SLIP RINGS

BRUSHES

LEADS

201

5H

+

-

LEADS

200A

200

TEST PROCEDURE

1. Perform the Case Cover Removal proce-

dure.

2. Connect the voltmeter probes to the brush

terminals. See Figure F.10. See the wiring

diagram.

3. Set the RUN/STOP switch to “RUN” and

the IDLE switch to “HIGH”. Start the engine

and allow the RPM to stabilize for about 15

to 30 seconds.

The meter should read 46 to 54 VDC.

4. Set the RUN/STOP switch to “STOP”

5. If the meter reading is normal, this test is

complete.

6. If the voltage measures zero or very near

zero, the rotor flashing circuit may be faulty

or the rotor may be shorted.

7. Perform the Rotor Resistance and

Ground Test and the Rotor Flashing

Voltage Test.

8. If voltage is higher than 54 VDC, the

engine RPM may be too high, or there may

be voltage intrusion from one of the higher

voltage stator windings to the stator exciter

winding. Perform the Engine Throttle

Adjustment Test, and the Stator Short

Circuit and Ground Test.

9. If the voltage is lower than 46, but high-

er than 14, the engine RPM may be too

low, or there may be problems in the wind-

ings or other exciter circuit components or

connections. Perform the Engine Throttle

Adjustment Test, and then perform the

testing described below, under the heading

“If the voltage measures about 3 to 5

VDC”