Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

TROUBLESHOOTING & REPAIR

F-31 F-31

RANGER 305D

ENGINE THROTTLE ADJUSTMENT TEST (continued)

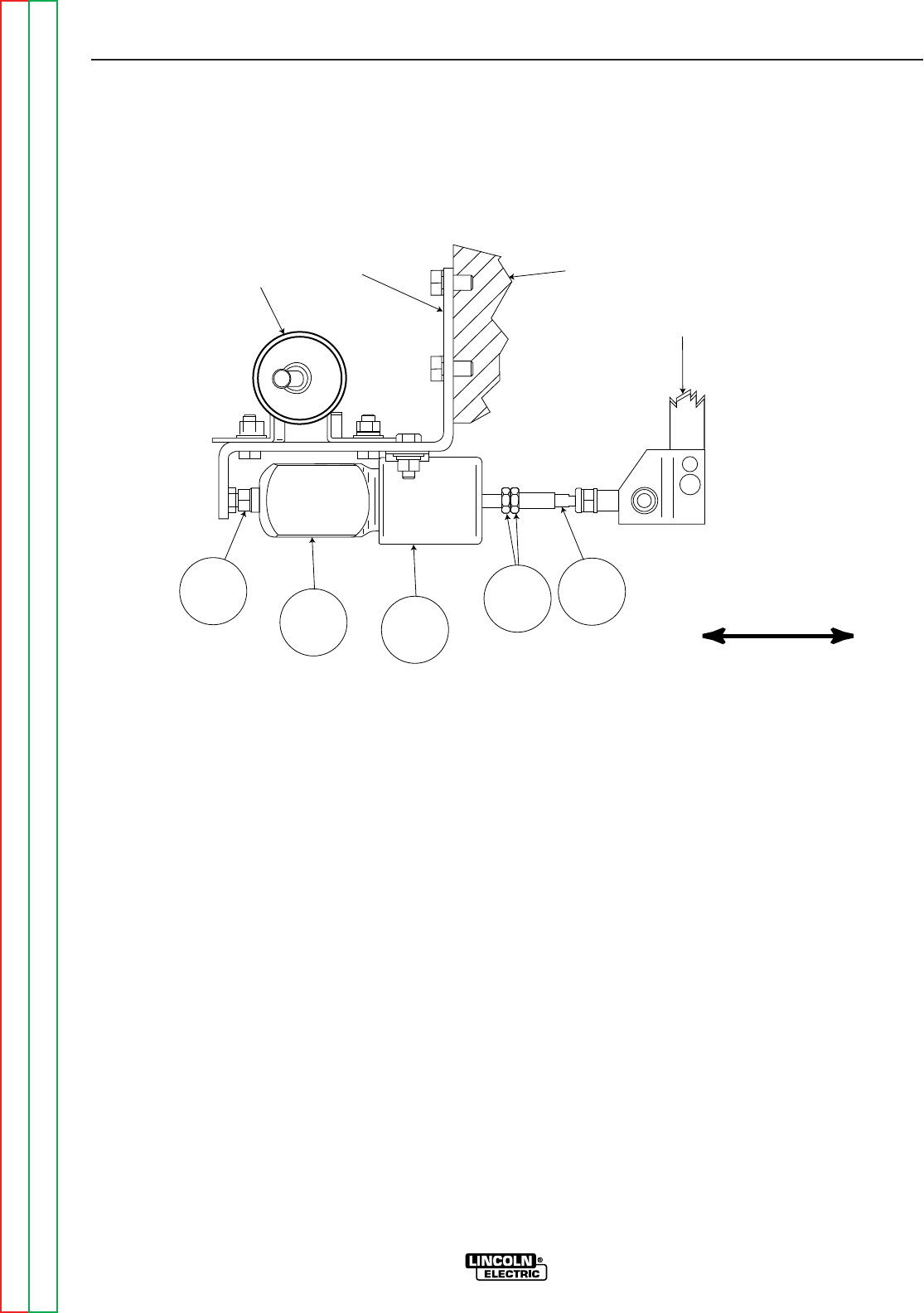

FIGURE F.6 – SOLENOID

Frequency Counter Method

NOTE: A dedicated frequency counter can be

used for this test, but many high quality digital

multimeters also have this function, and can be

easily utilized. See the manufacturer instruc-

tions for your frequency counter or multimeter.

1. Set your frequency counter per the meter

manufacturer instructions, and plug it into

one of the 120VAC auxiliary receptacles.

2. Start the engine and place the idle switch in

the “HIGH IDLE” position. Make sure that

there is no load on the machine.

The frequency should read between 60.5

and 61.5 Hz.

3. Move the idle switch to the “AUTO IDLE”

position and wait for the idle solenoid to

energize, and the engine RPM to drop and

stabilize at the low idle RPM.

The frequency should read between 40 and

42 Hz.

If either of the readings is incorrect, pro-

ceed to the “THROTTLE ADJUSTMENT

PROCEDURE” later in this section.

NOTE: For the Ranger 305D, and any other

Lincoln Electric 3600 RPM (2 Pole) machine,

engine RPM can be determined by multiplying

the frequency, in Hz. By 60. (Example: 60 Hz *

60 - 3600RPM)

Low Idle

Jam Nuts

Swivel

Fitting

Solenoid

Rubber

Boot

High Idle

Screw &

Jam Nut

Engine Speed

Control Lever

Engine

Solenoid & Fuel

Pump Bracket

Electric Fuel Pump

(codes 10926 &11121 only)

INCREASE

(RPM)

DECREASE

(RPM)

MOVING ENGINE

SPEED CONTROL

LEVER

• Solenoid viewed from above and shown in High Idle position •