Digital Dosing Units

30

• Enter the additive percentage by using the Arrow Keys . The

range of values that can be entered is 0.01 to 50.00%. The arrow keys are

used to change all process variables. The double arrow key allows the user to

ramp up or down at a faster rate.

Step 2:

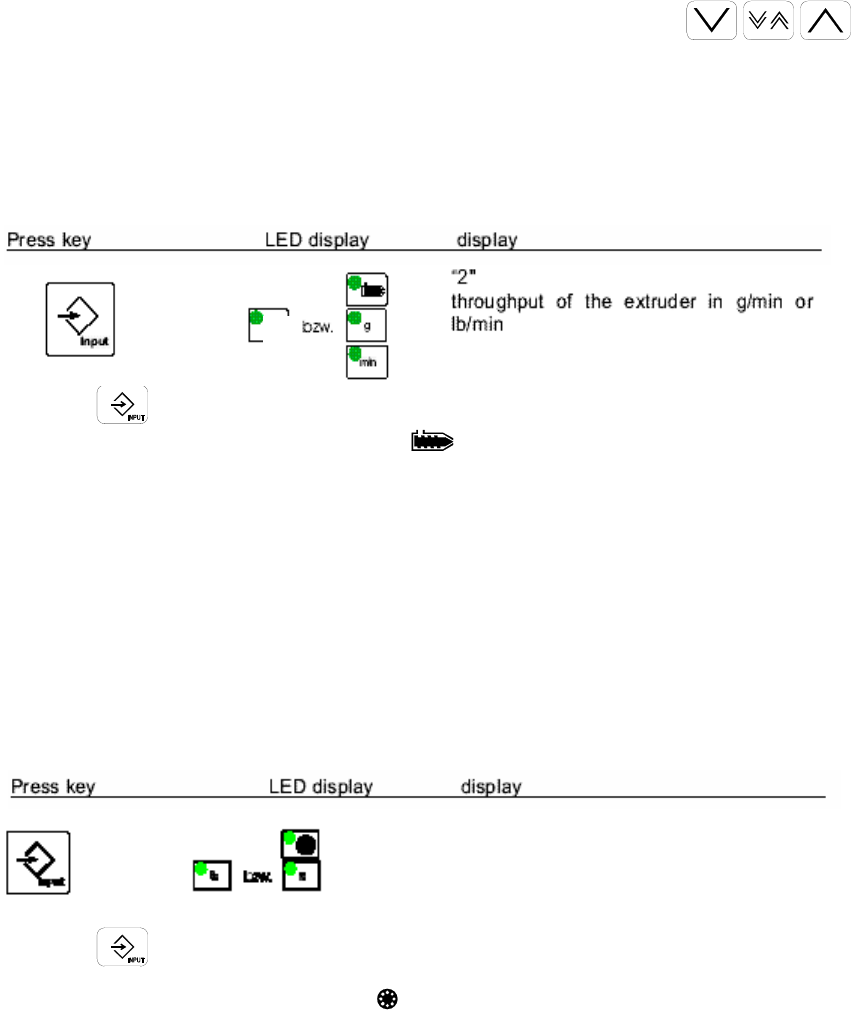

• Press again.

• The symbols “g,” or “lb”, “min”, and flash.

• After “2” flashes quickly on the display, a number in the format xxx.xx will come up on

the display.

• Enter the total extruder throughput in grams per minute or pounds per minute. The

range of values that can be entered is 001.0 to 6500 grams per minute (00.01 to 14.30

lb/m).

Extrusion Constant, parameter “3” is skipped.

Step 3:

“ 4 “ = calibration weight in grams or pounds

• Press a third time.

• The machine displays a flashing , “g” or “lb” and a number “4”flashes on the display

• After the “4” flashes on the display, a number in the format xxxx.x will come up.

• Enter the calibration weight in grams. If the calibration weight is unknown, enter

the appropriate “value” from Section 2, based on your disc size, to obtain a

starting weight.

• The range of values that can be entered in this field is 00.00 to 400.0.

Note: Parameters 5 and 6 will only be displayed when a mixer and

or a printer is configured.

or