Digital Dosing Units

5

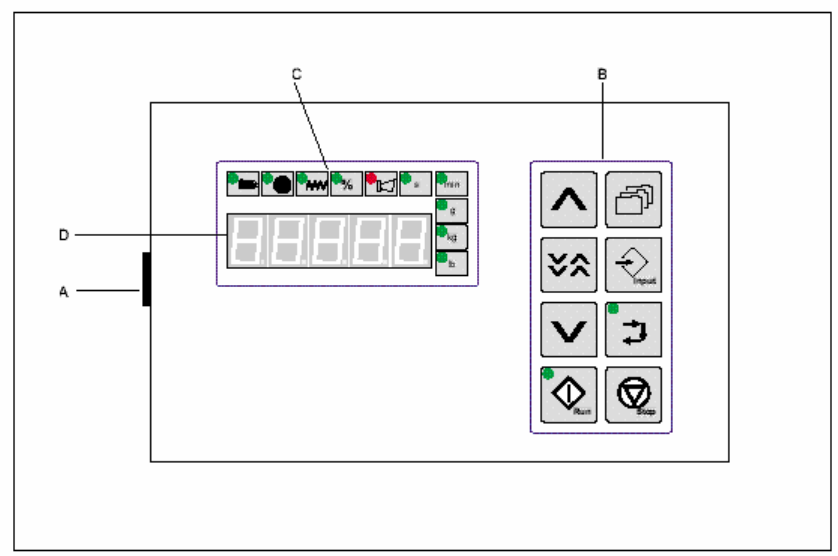

1.1 Controller

The Digital Dosing additive feeder consists of a controller(s), dosing motor(s), and feeder(s).

The controller is used to:

• Configure the unit to the desired process.

• Calibrate the feeder

• Run, monitor, and stop the dosing process

• Enter, recall, and run recipes

• Troubleshoot problems via error codes

A keypad and LED display (see Figure 3) are used to enter, or change, data.

• The control system is switched on (position “1") with the On/Off switch. (A)

• The control system is operated through the keypad. (B)

• The individual operating modes are indicated by symbols. (C)

• Messages appear on a 5-digit LED display. (D)

Figure 3. Keypad and LED Display