3. INSTALLATION

BAS-300G, BAS-311G, BAS-326G

12

3-9. Connecting the cords

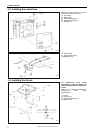

1. Gently tilt back the machine head.

2. Pass the cord bundle through the hole

in the work table.

3. Loosen the two screws (1), and then

open the cord presser plate (2) in the

direction of the right arrow and pass

the cord bundle through the opening.

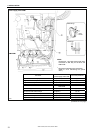

4. Securely connect the connectors as

indicated in the table below.

NOTE:

• Check that the connector is facing

the correct way, and then insert it

firmly until it locks into place.

• Secure the cables with cable ties

and cord clamps, while being careful

not to pull on the connector.

<Main PCB>

NOTE:

• Check that the connector is facing the correct

way, and then insert it firmly until it locks into

place.

• Secure the cables with cable ties and cord

clamps, while being careful not to pull on the

connector.

*

1

: Be sure to make the ground connection.

(Refer to "3-10. Connecting the ground

wire".)

Connector

Connection location on

main PCB

Cord clamp

X pulse motor encoder 5-pin white P20 (X-ENC) (3)

Y pulse motor encoder 5-pin blue P4 (Y-ENC) (3)

Work clamp pulse motor encoder 5-pin black P5 (P-ENC) (3)

Foot switch 10-pin P6 (FOOT) (3)

Operation panel 8-pin P1 (PANEL) (3)

Machine head switch 3-pin P9 (HEAD-SW) (4)

Home position sensor assembly 12-pin P8 (SENSOR1) (4)

STOP switch 6-pin P13 (HEAD) (4)

Valve harness 12-pin (pneumatic work clamp

specifications)

P12 (AIR1) (4)

Programmer relay harness 8-pin P7 (PRG) (3)

Solenoid selection harness 4-pin P3(CUTTER) -

(Continued on next page)

4924Q

Lock the cord

clamp securely.

1842B