10. STANDARD ADJUSTMENTS

BAS-300G, BAS-311G, BAS-326G

56

10-2. Thread take-up spring

Specifications

Heavy-weight materials

(-01[])

Medium-weight materials

(-02[])

Seatbelt (-03[])

Thread take-up spring

height (mm)

7 − 10 2 − 4

Thread take-up spring

tension (N)

0.6 − 1.2 0.2 − 0.5 1.0 − 1.4

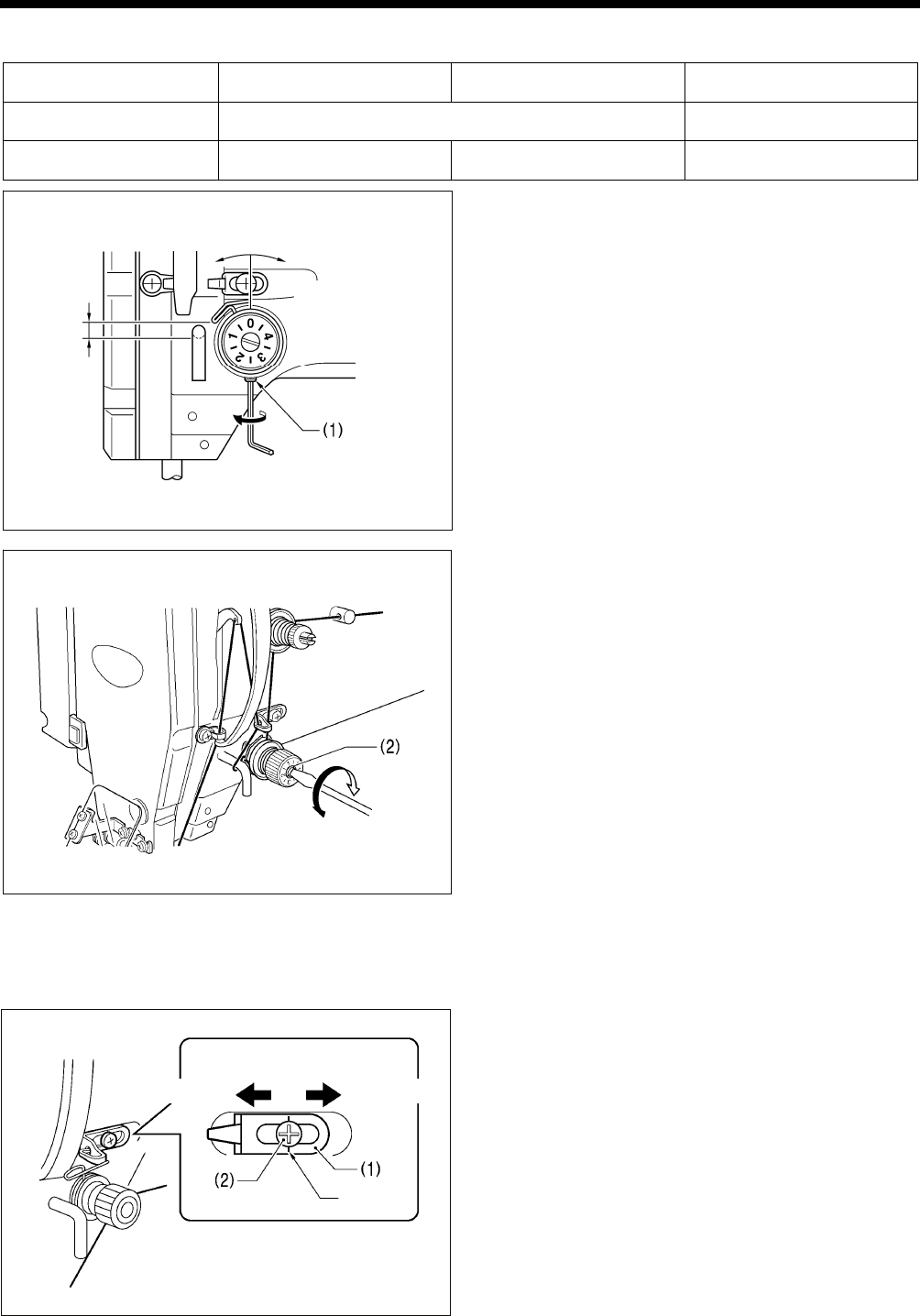

<Thread take-up spring height>

Loosen the set screw (1) and turn the adjuster to adjust.

<Thread take-up spring tension>

Turn the tension stud (2) with a screwdriver to adjust the

tension.

NOTE:

If the thread tension spring is not adjusted correctly, the upper thread trailing length will be uneven after thread trimming.

10-3. Arm thread guide R

The standard position of arm thread guide R (1) is when the

screw (2) is aligned with the index mark.

Loosen the screw (2) and move arm thread guide R (1) to

adjust.

* When sewing heavy material, move arm thread guide R

(1) to the left. (The thread take-up amount will become

greater.)

* When sewing light material, move arm thread guide R

(1) to the right. (The thread take-up amount will become

less.)

5022Q

Lower

Higher

2265B

5030

Q

Weaker

Stronger

More thread

Less thread

Index mark