10. STANDARD ADJUSTMENTS

BAS-300G, BAS-311G, BAS-326G

60

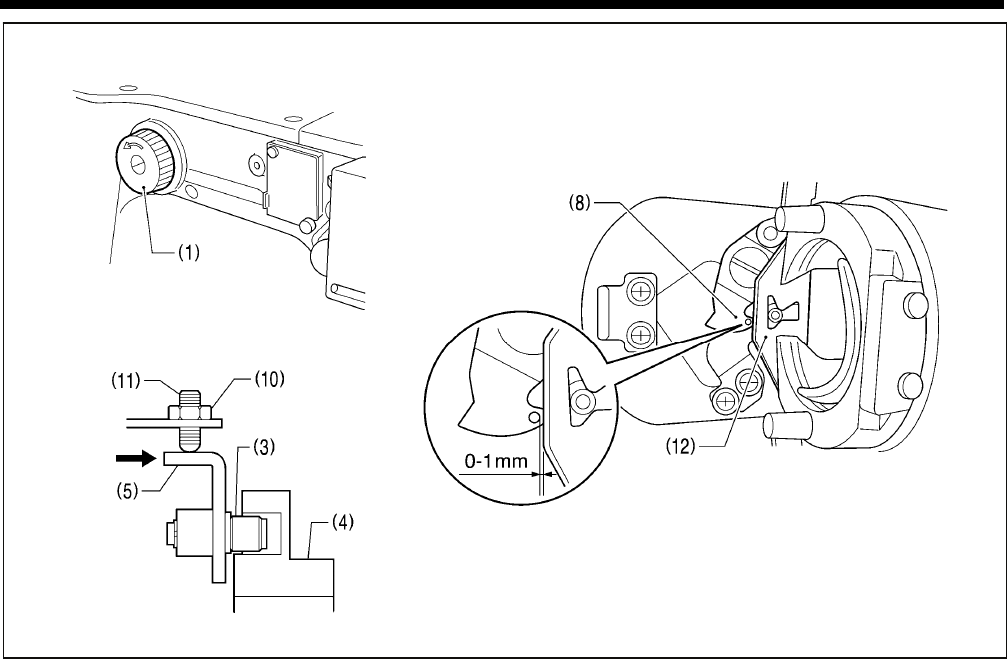

7. Turn the pulley (1) by hand in the direction of the arrow to move the needle bar to its lowest position.

8. Loosen the nut (10), tighten the set screw (11) until the collar (3) is touching the inside of the groove in the thread trimmer

cam (4), and then turn it back in the counterclockwise direction by approximately 1/4 of a turn.

9. Tighten the nut (10), and then check that the collar (3) is not touching the inside of the groove in the thread trimmer cam

(4). In addition, push the driving lever (5) by hand toward the thread trimmer cam until the collar (3) touches the groove of

the thread trimmer cam (4), and then check that the driving lever (5) returns smoothly to its original position when it is

released.

10. Check that there is a gap of about 0 - 1 mm between the outside of the hole in the movable knife (8) and the ridge line on

the shuttle race thread guide (12) when there is still play between the parts.

5238Q

5237Q

2979B