10. STANDARD ADJUSTMENTS

BAS-300G, BAS-311G, BAS-326G

57

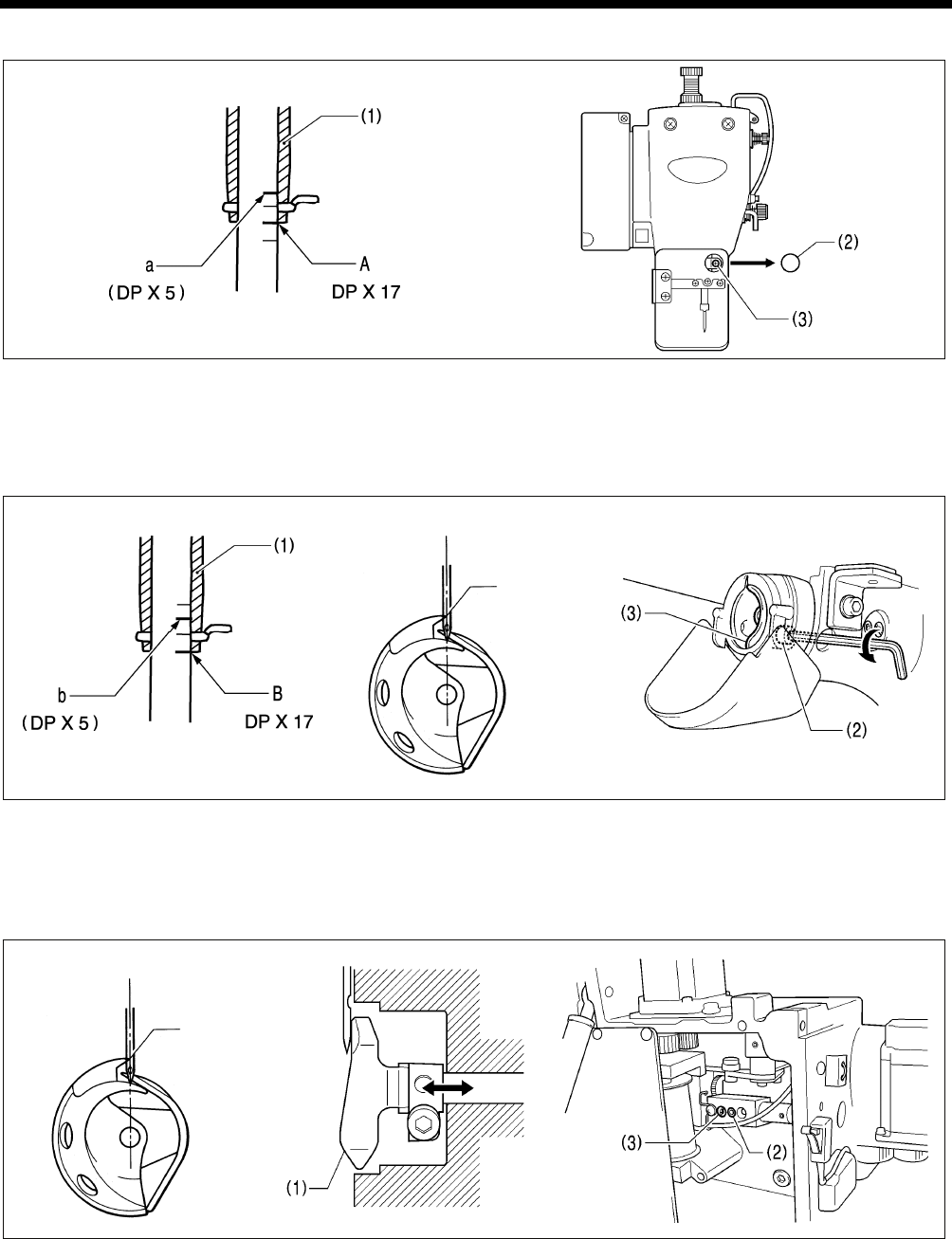

10-4. Adjusting the needle bar height

Turn the pulley in the direction of the arrow to move the needle bar to the lowest position. Then remove the rubber plug (2),

loosen the screw (3) and then move the needle bar up or down to adjust so that the second reference line from the bottom

of the needle bar (reference line A) is aligned with the lower edge of the needle bar bush (1).

* If using a DP X 5 needle, use the highest reference line (reference line a).

10-5. Adjusting the needle bar lift amount

Turn the pulley in the direction of the arrow to raise the needle bar from the lowest position until the lowest reference line on

the needle bar (reference line B) is aligned with the lower edge of the needle bar bush (1), and then loosen the bolt (2) and

move the driver (3) so that the tip of the rotary hook is aligned with the center of the needle.

* If using a DP X 5 needle, use the second reference line from the top of the needle bar (reference line b).

10-6. Adjusting the needle contact pressure of the driver

Turn the pulley in the direction of the arrow to align the tip of the rotary hook with the center of the needle, and then loosen

the set screw (2) and turn the eccentric shaft (3) to adjust so that the driver (1) is touching the needle.

NOTE:

If the driver (1) crosses the needle more than necessary, it will place a load on the needle, or it may cause poor thread

tension. Furthermore, if it does not cross the needle at all, the tip of the rotary hook will interfere with the needle and

skipped stitches may occur.

2552Q 2266B

2554Q 4993Q

2980B

Needle center

Rotary hook tip

0135Q

Needle center

Rotary hook tip

5227Q 0135Q