3. INSTALLATION

BAS-300G, BAS-311G, BAS-326G

18

3-16. Lubrication

CAUTION

Do not connect the power cord until lubrication is complete.

If the foot switch is depressed by mistake, the sewing machine might start operating and injury could result.

Be sure to wear protective goggles and gloves when handling the lubricating oil and grease, so that they do not get into

your eyes or onto your skin. If the oil and grease get into your eyes or onto your skin, inflammation can result.

Furthermore, do not drink or eat the lubricating oil or grease. They may cause diarrhea or vomiting.

Keep the oil out of the reach of children.

The sewing machine should always be lubricated and the oil supply replenished before it is used for the first time, and also after

long periods of non-use.

Use only the lubricating oil <JX Nippon Oil & Energy Corporation Sewing Lube 10N; VG10> specified by Brother.

* If this type of lubricating oil is difficult to obtain, the recommended oil to use is <Exxon Mobil Essotex SM10; VG10>.

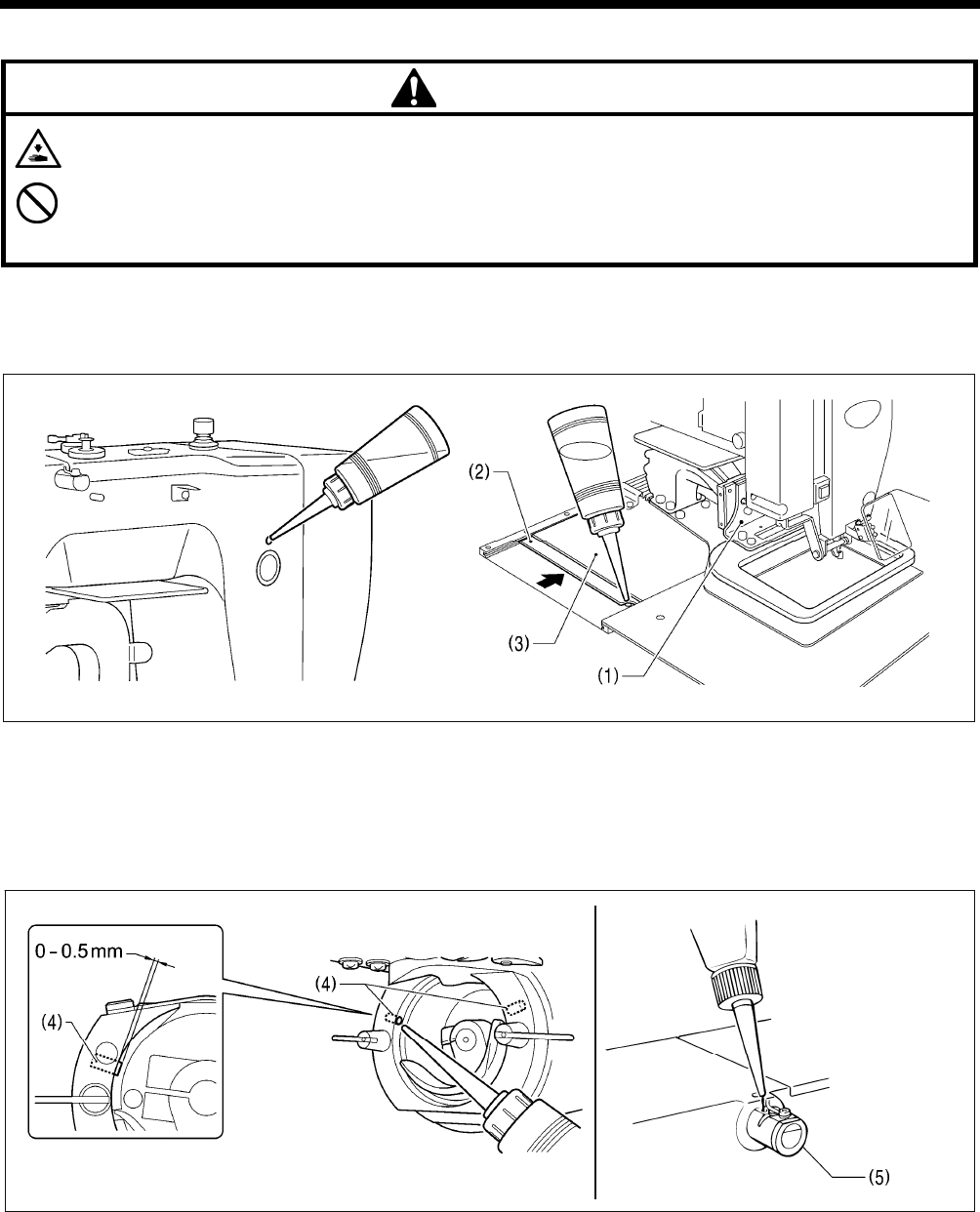

1. Fill the arm-side oil tank with oil.

2. Move the work clamp arm (1) as far as it will go to the right when looking from the front of the sewing machine, and then slide the

outer cover L (2) into the inner cover L (3) so that the lubrication hole in the bed is visible. Pour oil into the bed side oil tank

through this hole.

NOTE:

Be sure to fill the machine with oil when the oil level is down to about one-third full in the oil sight glass. If the oil drops below the

one-third level, there is the danger that the machine may seize during operation.

3. Pour oil in through the two holes of the shuttle race base assembly so that the felt (4) is lightly moistened.

NOTE:

・ The two pieces of felt (4) should normally project by 0 to 0.5 mm from the hook race. Be careful not to push in the felt (4)

when lubricating.

・ If there is no more oil on the felt (4) of the shuttle race base assembly, problems with sewing may result.

4. If using the needle cooler (5), fill it with silicon oil (100 mm

2

/s). (Refer to “4-2. Threading the upper thread”.)

1845B 4940Q

2368B

5221Q

<Standard parts>

・ BAS-300G-03[]

・ BAS-311G

・ BAS-326G

<Option parts>

・ BAS-300G-01[]

・ BAS-300G-02[]