308584 19

Operation

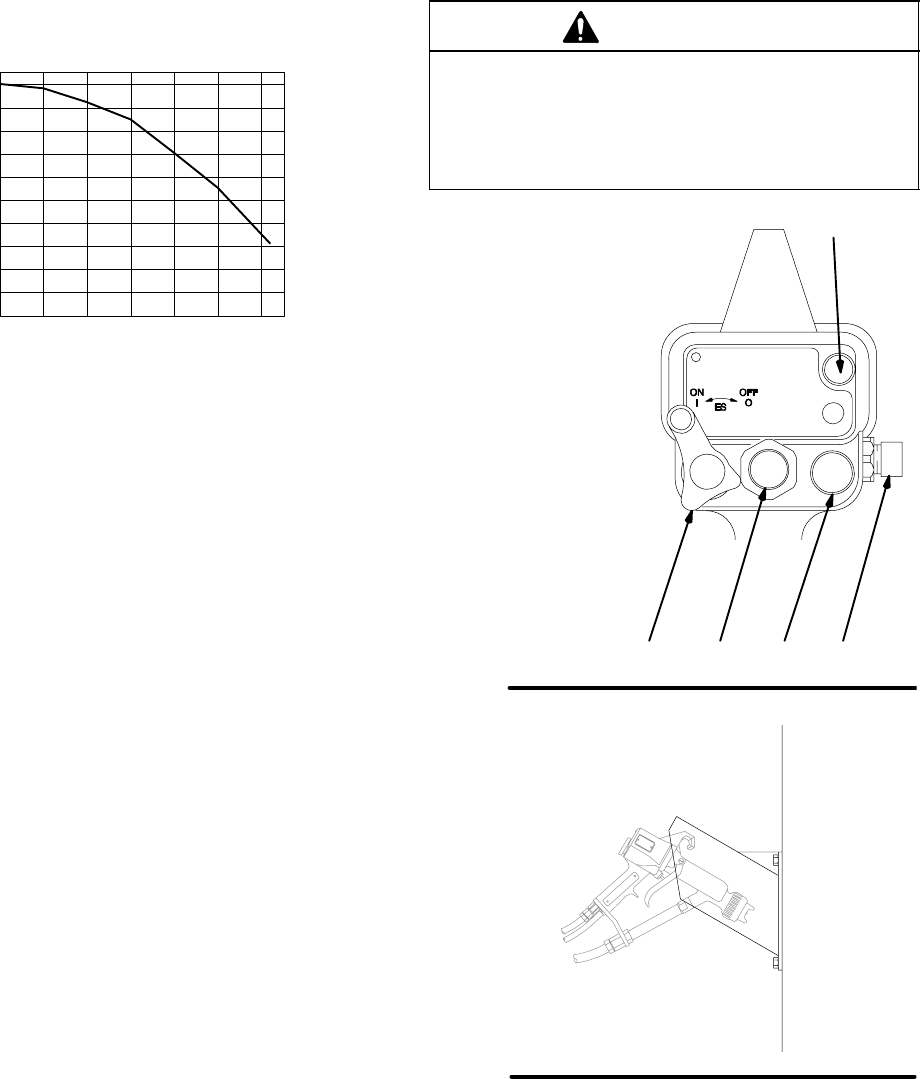

7. Set the atomizing air valve (R) about 1.5 turns out

for most applications. The Atomizing Air Valve

Adjustment chart shows the effect of the atomiz-

ing air valve adjustment on the air cap air flow.

8. Adjust the pattern width with the fan air valve (P).

Atomizing Air Valve Adjustment

0

10

20

30

40

50

60

70

80

90

100

0.00 0.50 1.00 1.50 2.00 2.50 3.00

Air Cap Air Flow (%)

Valve Turns

Fully Open Fully Closed

Fine Adjustments of the Spray Gun

D To improve the atomization, open the atomizing air

valve further (R). If more atomizing air is needed

beyond the fully open position of the valve, increase

the air hose inlet pressure.

Use the lowest air flow settings needed for accept-

able atomization. The slower particle velocity will

improve the electrostatic effect.

D To reduce the atomization air and minimize any

overspray, turn the atomizing air valve in.

9. Turn the ES ON-OFF lever (N) to ON to begin

spraying with the electrostatics. When spraying,

the ES indicator light (M) should glow, indicating

the electrostatic charge.

NOTE: See Spray Pattern Troubleshooting on page

25 to correct spray pattern problems. See Voltage

Loss Troubleshooting on page 22 to correct voltage

problems.

10. Operate the voltage isolation system as instructed

in the system manual. Normal spraying voltage for

the system will be 45 to 55 kV.

11. Use the same spraying technique you would use

with a conventional air spray system to coat the

workpiece.

12. Relieve the pressure and discharge the voltage

when you stop spraying.

CAUTION

Hang the gun with its nozzle pointing down when it is

not being used to avoid having fluid run into the gun

air passages. See Fig. 11. Fluid in the gun air pas-

sages can cause poor atomization and excessive

current demands and damage the gun.

Fig. 10

05151A

P*N R

M

J

KEY-Fig. 10

J Fluid Adjustment Knob

M ES Indicator Light

N ES ON-OFF Lever

P Fan Air Adjustment Valve

R Atomizing Air Valve

Fig. 11

05424