44 308584

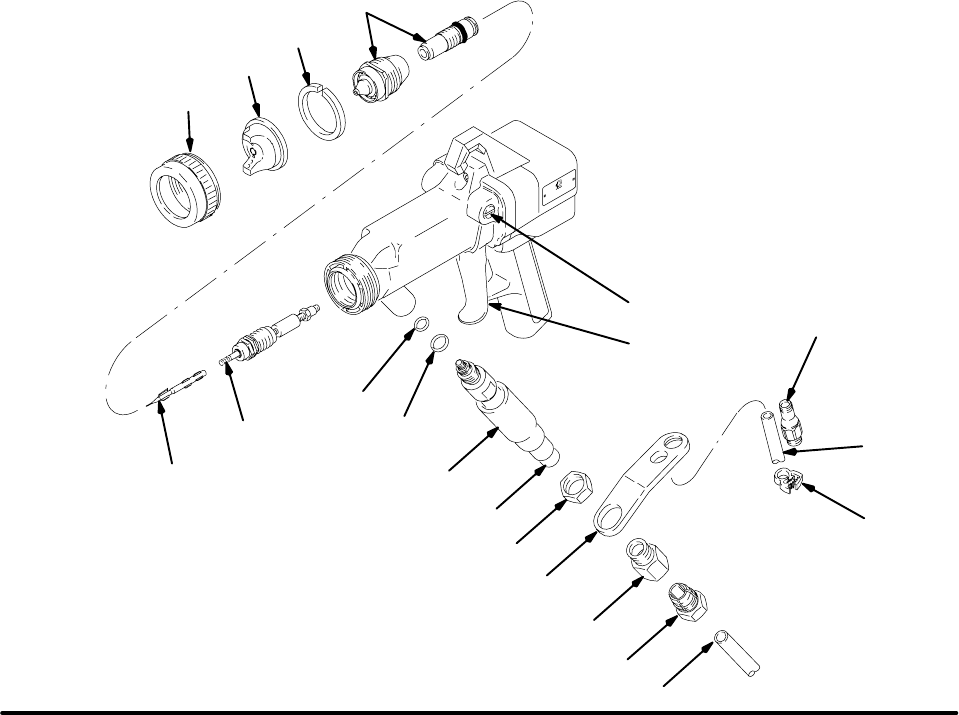

PRO 3500sc Gun Conversion

Fig. 31

8*

H

20*

L

28*

N

P

M

*80

91

*75

*78

*76

*79

*77

D

E

F

Apply a very light coat of lubricant to the o-ring on the

outside of the fluid packing rod (28).

Apply dielectric grease to the o-rings (80, 81) and tube (75)

threads.

Apply high strength Loctiter to the air fitting (D) threads.

Torque the fitting to 35 to 45 in-lbs (4 to 5.1 NSm).

Z

*81

05164B

Installing the Fluid Needle Assembly

NOTE: The parts marked with an asterisk (*) are

included with the conversion kit, part no. 223114.

1. Before installing the new fluid packing rod assem-

bly (28*), clean the internal surfaces of the barrel

with a soft brush or cloth. Check the inside of the

barrel for marks from high voltage arcing. If the

marks are present, replace the barrel.

2. Lubricate the o-ring on the outside of the fluid

packing rod assembly. Make sure the spring is in-

stalled on the fluid packing rod nut.

NOTE: See Fig. 20, page 34, for information on indi-

vidual fluid packing rod parts.

3. Install the fluid packing rod assembly (28*) into the

gun barrel. See Fig. 31. Using the 9 mm hex nut

driver, tighten the assembly until just snug, then

check the drag on the fluid rod. The fluid rod

packing nut is properly tightened when there is 2

lbs. (9 N) of drag force. Tighten or loosen the

packing nut as needed.

4. Install the trigger (L) and tighten the trigger

screws (K).

5. Install the electrode needle (20*), fluid nozzle and

resistor stud assembly (H) and the air cap assem-

bly (P, 8*, Z) as instructed on page 32.