42 308584

Service

Graco Waterborne Fluid Hose Repair

WARNING

FIRE, EXPLOSION, AND ELECTRIC

SHOCK HAZARD

To reduce the risk of a fire, explosion, or

electric shock:

D Follow the Fluid Voltage Discharge

and Grounding Procedure on page

16 and be sure the ES ON-OFF lever

is turned to OFF before flushing,

checking, or servicing the system and

whenever you are instructed to dis-

charge the voltage.

D Clean all the parts with a non-flammable fluid as

defined on the front cover of this manual.

D Do not service this equipment unless you are

trained and qualified.

D Do not touch the gun nozzle or come within 4

inches (101.6 mm) of the nozzle during gun op-

eration or until after following the Fluid Voltage

Discharge and Grounding Procedure..

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of an injury, follow the Pressure

Relief Procedure on page 16 before checking or

servicing any part of the system and whenever you

are instructed to relieve the pressure.

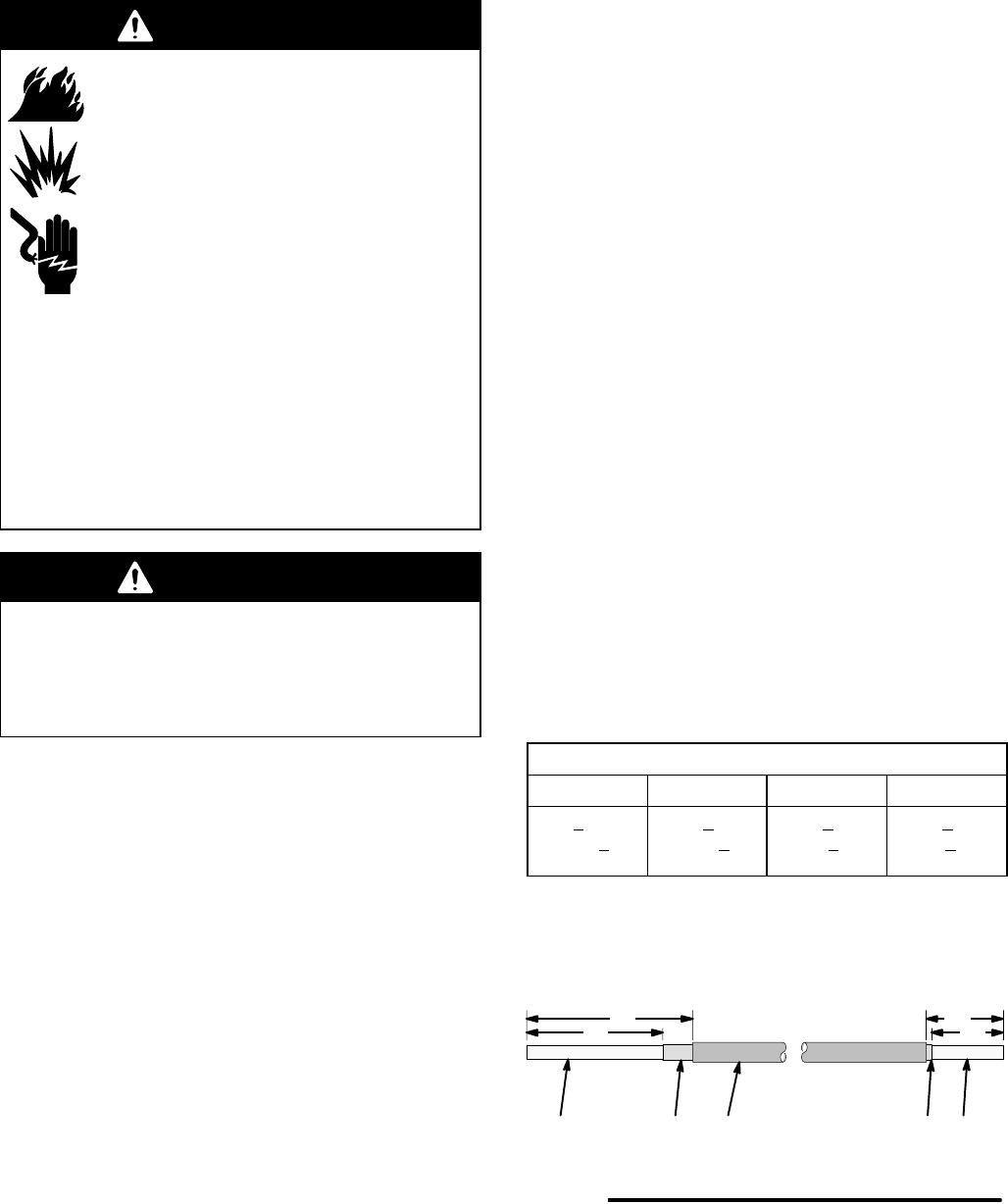

Damaged hoses or hoses that have a “pin-hole” dielec-

tric failure, close to the end of the hose, can be re-

paired by cutting away the failed portion and restrip-

ping the hoses to the dimensions shown in Fig. 29.

1. Discharge the voltage as instructed on page 16.

2. Relieve the system pressure as instructed on page

16.

3. Disconnect the fluid hose from the gun and voltage

isolation system.

4. Cut off the damaged end of the hose. If the hose

has a pin-hole failure, strip back the outer hose

jacket (H) and the conductive layer (J) about 12

inches (105 mm) on each hose end. Look for the

failure point, which will be a very small pin-hole,

discolored due to arcing. Continue stripping back

the hose until the failure point is found.

5. Carefully cut through the outer hose jacket (H) and

peel it back about 12 inches (105 mm). Do not cut

into the conductive layer (J) of the hose.

6. Cut through the first 1/2 inch (12.7 mm) of the

conductive hose layer (J) to create an edge to hold

onto. Peel back the conductive hose layer by

unwrapping it in a spiral pattern. Cut it off at the

dimension shown in Fig. 29.

7. Cut off the inner hose layer (K) to the dimension

shown in Fig. 29.

8. Inspect the hose for any nicks or cuts. Any nicks

or cuts into the inner hose layer (K) will weaken

the dielectric strength of the hose and shorten the

service life. Repeat the above procedure if any

damage is found.

9. Install a new barbed fitting by applying red dielec-

tric grease to the outside of the barbs, and press-

ing the fitting into the gun end of the hose. Refer to

the drawing of the Waterborne Fluid Hose Assem-

bly on page 48.

10. Install the three o-rings on the barbed fitting.

11. Connect the fluid hose to the gun as instructed on

page 12.

Measurements, inches (mm)

A* B* C D

7.75 + 0.1

(196.85 +

2.5)

9.375 + 0.1

(238.13 +

2.5)

4.075 + 0.1

(103.5 + 2.5)

4.375 + 0.1

(111.1 + 2.5)

* The measurements specified are for use with the Graco

H

2

O PRO Voltage Block isolation system.

Fig. 29

H

JK

05180

A

B

D

Isolation System End Spray Gun End

J K

C