134

Chapter 9 - Appendix

When Good Results Are Not Obtained

☞ See p.124 "Problems with Engraving"

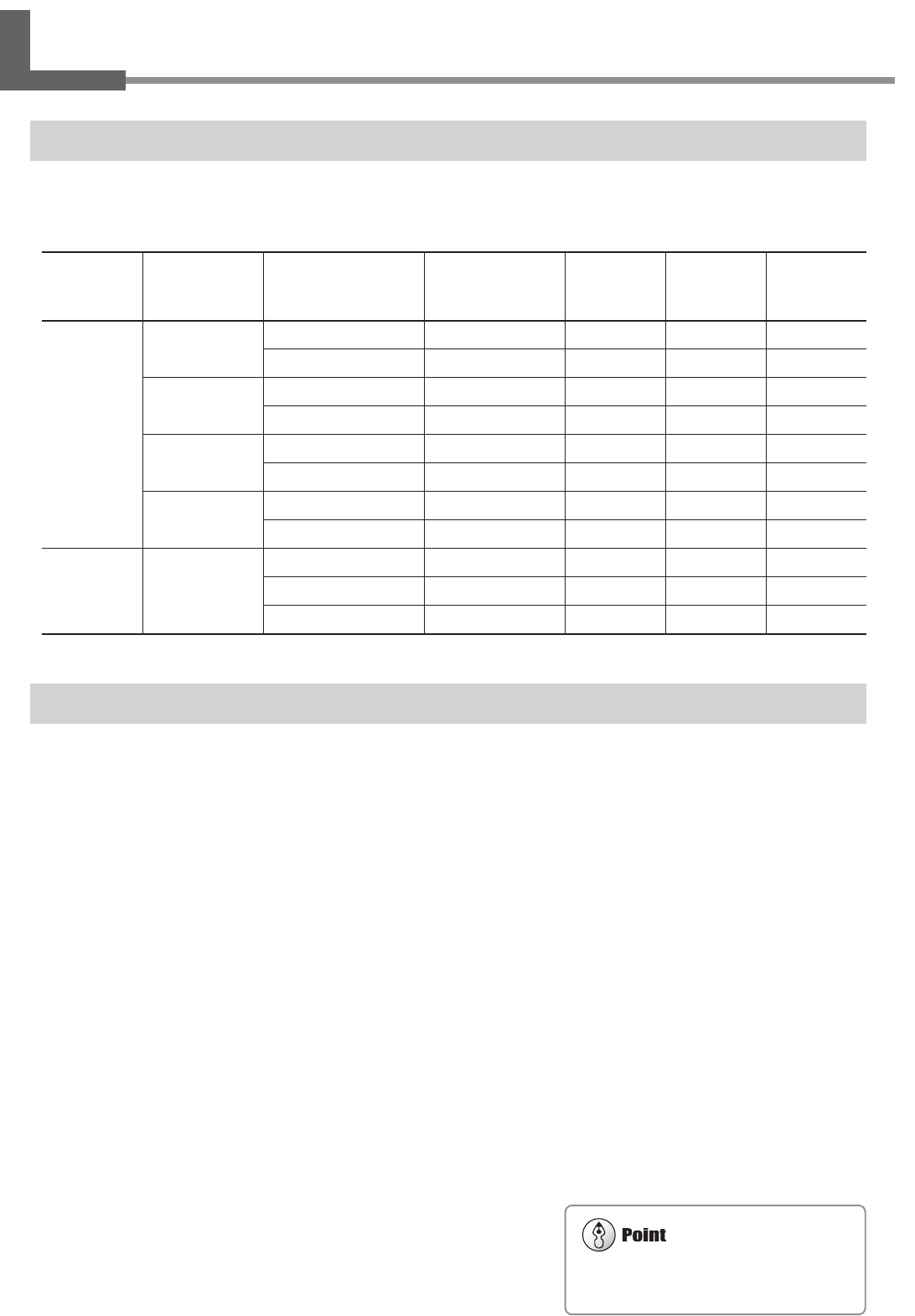

9-1. Examples of Settings for Cutting Parameters

Sample Settings for Engraving

This is a suggested guide for cutting parameters. Fine-tuning the settings may be necessary. Adjust these a little at a time

as you examine the results, seeking the parameters that best match the workpiece.

Tips for Fine-tuning

The optimal cutting parameters are determined by a balance of such factors as the hardness of the material, the feed rate,

the spindle rotating speed, the cutting-in depth, and the capacity of the cutter. Refer to the following tips and try fine-

tuning the parameters.

Spindle Rotating Speed

In general, faster rotation provides increased cutting capacity. However, a feed rate that is too slow with respect to the

spindle speed may lead to melting of the workpiece due to heat, or to increased burring or roughness. Roughness may

also occur at some places because feed stops momentarily at places where the direction of engraving changes (that is, at

corners). Lower the spindle speed. It may also be a good idea to use faster settings for narrower cutters and slower

settings for wider cutters.

Feed Rate

Faster speeds result in shorter cutting times, but the cutting load also increases accordingly. The load may overcome the

strength with which the workpiece is secured in place, resulting in crooked lines or a nonuniform cutting-in depth. Also,

a feed rate that is too fast for the spindle rotating speed may result in roughness or a raised nap. Lower the feed rate.

Cutting-in Depth

Deeper cutting-in results in a greater cutting load, and roughness becomes more likely. When you make the cutting-in

deeper, it is a good idea to raise the spindle speed and lower the feed rate accordingly. Note, however, that there is a limit

to the maximum depth. When deep cutting-in is required, it is a good idea to perform double cutting and reduce the

amount of cutting-in per pass.

Engraving

Cutting out

Workpiece

Acrylic resin

Aluminum

Brass

ABS

ABS

XY-axis

feed rate

15 mm/s

15 mm/s

15 mm/s

15 mm/s

15 mm/s

15 mm/s

20 mm/s

15 mm/s

30 mm/s

30 mm/s

30 mm/s

Z-axis

feed rate

15 mm/s

5 mm/s

15 mm/s

15 mm/s

15 mm/s

15 mm/s

20 mm/s

15 mm/s

10 mm/s

10 mm/s

10 mm/s

Spindle speed

20,000 rpm

20,000 rpm

22,000 rpm

Without rotation

22,000 rpm

Without rotation

20,000 rpm

20,000 rpm

22,000 rpm

19,000 rpm

16,000 rpm

Cutting-in

depth

per pass

0.2 mm

0.2 mm

0.02 mm

Auto

0.02 mm

Auto

0.5 mm

0.4 mm

0.4 mm

0.4 mm

0.4 mm

Tool

ZEC-A4025

ZEC-A4430

ZEC-A4013-BAL

ZDC-A4000

ZEC-A4013-BAL

ZDC-A4000

ZEC-A4025

ZEC-A4430

ZHS-100

ZHS-200

ZHS-300