Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

B-5

OPERATION

B-5

S1 switch 7 ON = 4-Step without current interlock

operation:

1. Closing Trigger initiates gas flow.

2. Opening Trigger initiates gas preflow timer fol-

lowed by Run-in speed and strike voltage until

arc strike initiates welding. (Trigger is released

before arc is struck, but once established break-

ing arc stops the feeder operation).

3. Reclosing Trigger stops wire feed and initiates

burnback time, then gas postflow time.

4. Reopening Trigger stops gas flow if, or when,

postflow time is over.

Low Security Mode Selection

The DH-10 Control is set up for Low Security Mode

(See “Security Modes” in this section) by setting S1

DIP Switch 8 (Labeled “S”):

S1 switch 8 ON = Low Security mode ON

S1 switch 8 OFF = Low Security mode OFF (as

shipped)

NOTE: High Security mode must be OFF for Low

Security mode to function.

High Security Mode Selection

The DH-10 Control is set up for High Security Mode

(See

Security Modes

in this section) by setting S1

DIP switch 5 (Not labeled):

S1 switch 5 ON = High Security mode ON

S1 switch 5 OFF = High Security mode OFF (as

shipped)

DH-10

Security

Pwr Sources

M 4

S1

ON

S1

1 2 3 4 5 6 7 8

Security

Pwr Sources

M 4

S1

ON

S1

1 2 3 4 5 6 7 8

Security

Pwr Sources

M 4

S1

ON

S1

1 2 3 4 5 6 7 8

Security

Pwr Sources

M 4

S1

ON

S1

1 2 3 4 5 6 7 8

Security

Pwr Sources

M 4

S1

ON

S1

1 2 3 4 5 6 7 8

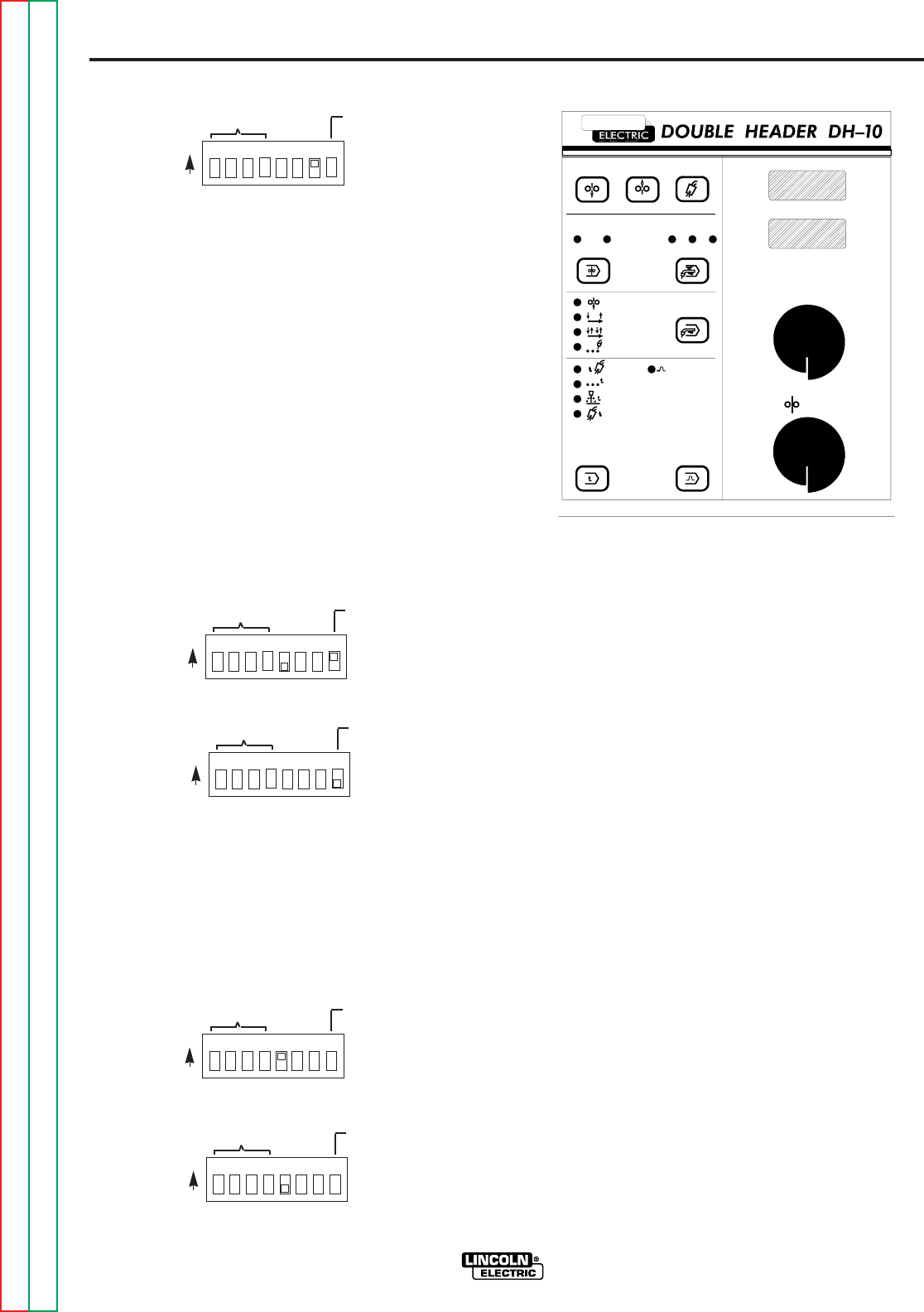

Keypad and Display Description

Keypad - Eight key, membrane type with “snap” tac-

tile feel and embossed domes. Long life design.

Spatter resistant surface.

Displays - Two digital LED displays with 0.56 in.

(14.2 mm) character height. Top (3-1/2 digit) displays

Preset and Actual (while welding) arc voltage in volts

with (+) or (-) polarity indicators, and also displays all

timers in seconds. Bottom (4 digit) displays preset

wire feed speed in IPM, or m/m, and acceleration

selection.

Indicator Lights - Extra bright red LEDs for viewing

at almost any angle. Always indicate the feeder and

procedure selected, trigger mode being used and

function or timer being displayed.

Rotating Encoders - Knob controls increase or

decrease settings of volts and wire feed speed

(initially factory set to minimum). Alternately, the top

encoder adjusts timer settings and bottom selects

acceleration settings when selected for these

parameters to be displayed.

Power-Down Save

Power to the DH-10 is supplied and controlled from

the power source. The DH-10 automatically senses

the loss of power when the power source is turned off.

KEYPAD AND DISPLAY OPERATION

VOLTS / WFS

SPOT

VOLTS

FEEDER

WIRE FEED SPEED

RUN-IN

BURNBACK

SPOT

PREFLOW

1

2

GAS PURGE

1

FORWARD

COLD FEED

2

POSTFLOW

G3030

R

LINCOLN

REVERSE

COLD FEED

THE LINCOLN ELECTRIC COMPANY CLEVELAND, OHIO U.S.A.

A

B

PROCEDURE

TRIGGER

COLD FEED

2-STEP STD

4-STEP LOCK

V

REMOTE

WFS

V

TIMER

CONTROL