Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

B-7

OPERATION

B-7

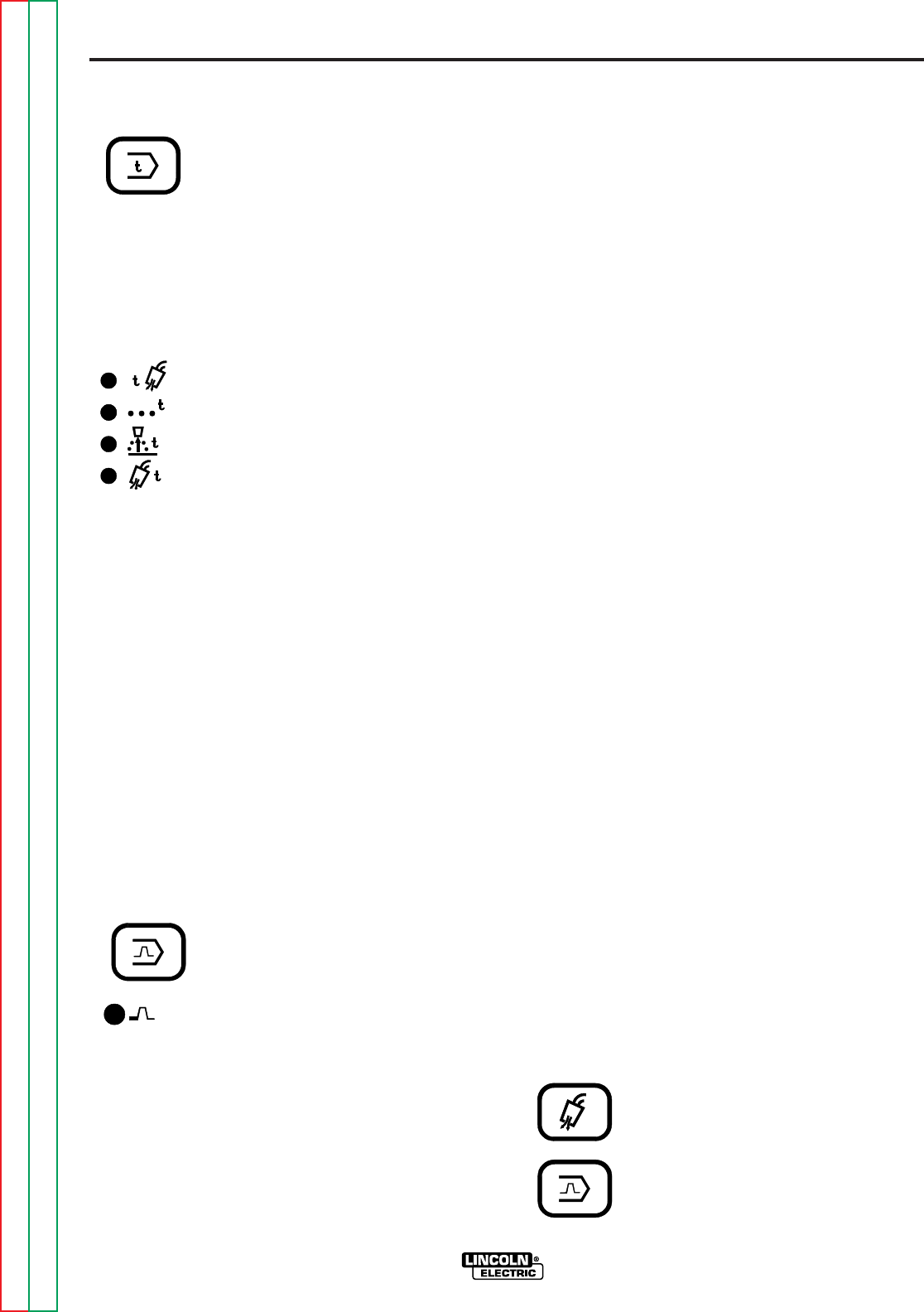

Display Control Keys

Timer Select key - enables operator to

choose burnback, spot or gas timers, as

indicated by the appropriate light.

Pressing the key causes lights to

sequence (top to bottom, then all off) starting from the

current indicated selection.

When a timer is selected the Voltage display shows

the time setting in seconds, as indicated by “SEC” dis-

played on the speed display. The times are set using

the Voltage encoder knob.

Top Light - indicates preflow time

is being displayed, settable 0.0 to

2.5 seconds (0.2 sec as shipped).

This is the time the shielding gas

flows before the wire feed and

power source are activated.

Second Light - indicates spot time is being displayed,

settable 0.0 (as shipped) to 199.9 seconds.

Third Light - indicates burnback time is being dis-

played, settable 0.00 (as shipped) to 0.25 seconds.

This is the time the arc power is delayed at the stop of

the weld, and should be set to the lowest time

required to prevent the wire sticking in the weld.

Bottom Light - indicates postflow time is being dis-

played, settable 0.0 to 10.0 seconds (0.5 sec as

shipped).

This is the time the shielding gas flows after the wire

feed and power source are deactivated.

Pressing Timer Select Key again, or closing the gun

trigger, shuts all timer lights off, indicating weld

Voltage and Wire Feed Speed are again being dis-

played, and set by the appropriate encoder knob.

Control Select key - enables

operator to choose Run-In

procedure as indicated by the light

turning on. When light is on, the

settings of Run-In Wire Feed

Speed and Voltage are displayed.

After Weld procedure is set, Run-

in procedure should be set to

optimize arc starting.

Speed encoder knob can adjust run-in speed between

min. rated speed and up to the procedure Weld speed

setting. Run-in speed setting can not exceed Weld

speed setting. Run-in speed setting of 100 IPM or less

is recommended for optimum starting. Factory setting

is near min. rated speed.

DH-10

TIMER

BURNBACK

SPOT

PREFLOW

1

2

POSTFLOW

CONTROL

VOLTS / WFS

RUN-IN

If set below minimum rated speed “---” will show on

the WFS display, indicating Run-in speed is set to

match weld speed setting.

The Run-in (strike) voltage can be set above or below

the Weld voltage setting up to a max of 60 V. If set

below a min of 10 V, the Run-In (strike) voltage dis-

play shows “---”, indicating the Run-In Voltage is set to

match the weld voltage setting. Also, the difference

between Run-in voltage and Weld voltage settings is

maintained automatically if the Weld voltage setting is

changed, so the run-in voltage encoder knob does not

need to be changed to follow the Weld voltage setting.

When trigger is closed (and preflow time is over) the

wire feeds at Run-In speed and volts until the welding

arc strikes, which causes the feed speed and volts to

change to Weld settings.

If the arc does not strike within about 2 seconds, the

Run-In speed automatically changes to Weld speed to

permit “Hot” feeding at higher speed setting for load-

ing wire.

Pressing control key again, or closing the gun trigger,

shuts off light indicating knob settings and displays

are returned to Weld Voltage and Wire Feed Speed.

Digital “Memory” Voltmeter

When the welding gun trigger is activated, the top DH-

10 display reads actual welding voltage from 0.0 to

60.0 VDC with automatic polarity indication for posi-

tive (+) or negative (-) electrode.

If actual voltage drops below 8.0 volts for over 0.8 sec

when the trigger is closed, Loss of Voltage Sense

Shutdown will occur. See “Loss of Voltage Sense

Shutdown” in this section.

The last welding voltage monitored at the end of the

weld is displayed for 5 seconds after the weld has

stopped, as indicated by a 5 second “blinking” display.

This allows checking actual weld voltage after weld

has stopped.

Any keypad or trigger operation will interrupt the 5

second memory display.

Acceleration Selection

To provide optimum starting of various

processes and procedures, the wire

feed acceleration of the DH-10 can be

set to five levels; 1 thru 5, for each feed-

er and procedure. 1 is the slowest

acceleration and 5 is the fastest.

GAS PURGE

CONTROL