RECOMMENDED APPLICATIONS

WELDER

The RANGER 9 provides excellent constant current

AC/DC welding output for stick (SMAW) welding and

for TIG welding, and it offers constant voltage output

for DC semiautomatic wire feed welding. For more

details on using the machine as a welder, see WELD-

ING OPERATION in the Operation section of this

manual.

GENERATOR

The RANGER 9 gives AC generator output for medium

use demands. For more details on operating the gen-

erator, see AUXILIARY POWER in the Operation sec-

tion of this manual.

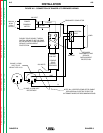

OPERATIONAL FEATURES AND

CONTROLS

The RANGER 9 was designed for simplicity. There-

fore, it has very few operating controls. Three switch-

es are used for welding operations:

• A nine-position output range selector switch selects

current output for constant current stick or TIG

applications and constant voltage wire feed appli-

cations.

• A fine output control switch for fine adjustment of

current or voltage within the selected output range

• A three-position polarity switch for selecting DC+,

DC- or AC welding output.

• A two-position toggle switch for selecting between

CONTROL AT WELDER or REMOTE CONTROL

(Remote control connections are made at either the

6 pin or the 14 pin amphenol connector.

• A two-position toggle switch for selecting between

control of the output contactor by the RANGER 9

(WELDING TERMINALS ALWAYS ON) or control of

the output contactor by a cable from a wire feeder

gun (WELDING TERMINALS REMOTELY CON-

TROLLED).

The gasoline engine control is a three-position toggle

switch for START, RUN, and STOP and a two-position

“IDLER” switch that selects engine speed for welding

or auxiliary power applications. See ENGINE OPERA-

TION in the Operation section of this manual for

details about starting, running, stopping, and breaking

in the gasoline engine.

DESIGN FEATURES AND

ADVANTAGES

• 9,000 watts of auxiliary power

• Enhanced constant voltage capability with low (12-

21 volts), medium (15-27 volts), and high (18-35

volts) range settings for greater control of wire feed

applications.

• Built-in contactor with front panel selection of

“cold” or “hot” welding terminals: Cold (WELDING

TERMINALS REMOTELY CONTROLLED) – Closing

wire feeder trigger switch or amptrol causes con-

tactor to close and engine to accelerate to high idle.

Hot (WELDING TERMINALS ALWAYS ON) – The

contactor is closed and welding begins when elec-

trode touches work; engine automatically goes to

high idle.

• Constant current AC/DC Stick welding (SMAW)

process capability with output range from 40-250

amps (AC) or 40-250 amps (DC).

• Constant voltage DC Semiautomatic Wire Feed

Welding with output range from 40-250 amps.

• Constant current AC/DC TIG Welding with output

across the entire range of settings.

• Polarity switch for selecting DC+, DC-, or AC weld-

ing output.

• Separate ground stud for safe connection of case to

earth ground.

• Single 50 amp, 230 volt, full 9 kVA auxiliary power

receptacle.

• Double duplex 20 amp, 115 volt auxiliary power

receptacles.

• Electric starting.

• Battery Charging Ammeter.

• Engine Hour Meter for determining periodic mainte-

nance.

• Top-of-the-line 18 HP Onan P218 Performer

®

engine.

• Durable, heavy-gauge steel case.

• Built-in feet for easy mounting to truck bed or trailer.

• Bottom-mounted 10 gallon (38.0 litre) fuel tank with

convenient top fill and fuel gauge.

OPERATION

B-3 B-3

RANGER 9 RANGER 9

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC