ACCESSORIES

C-9 C-9

RANGER 9 RANGER 9

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

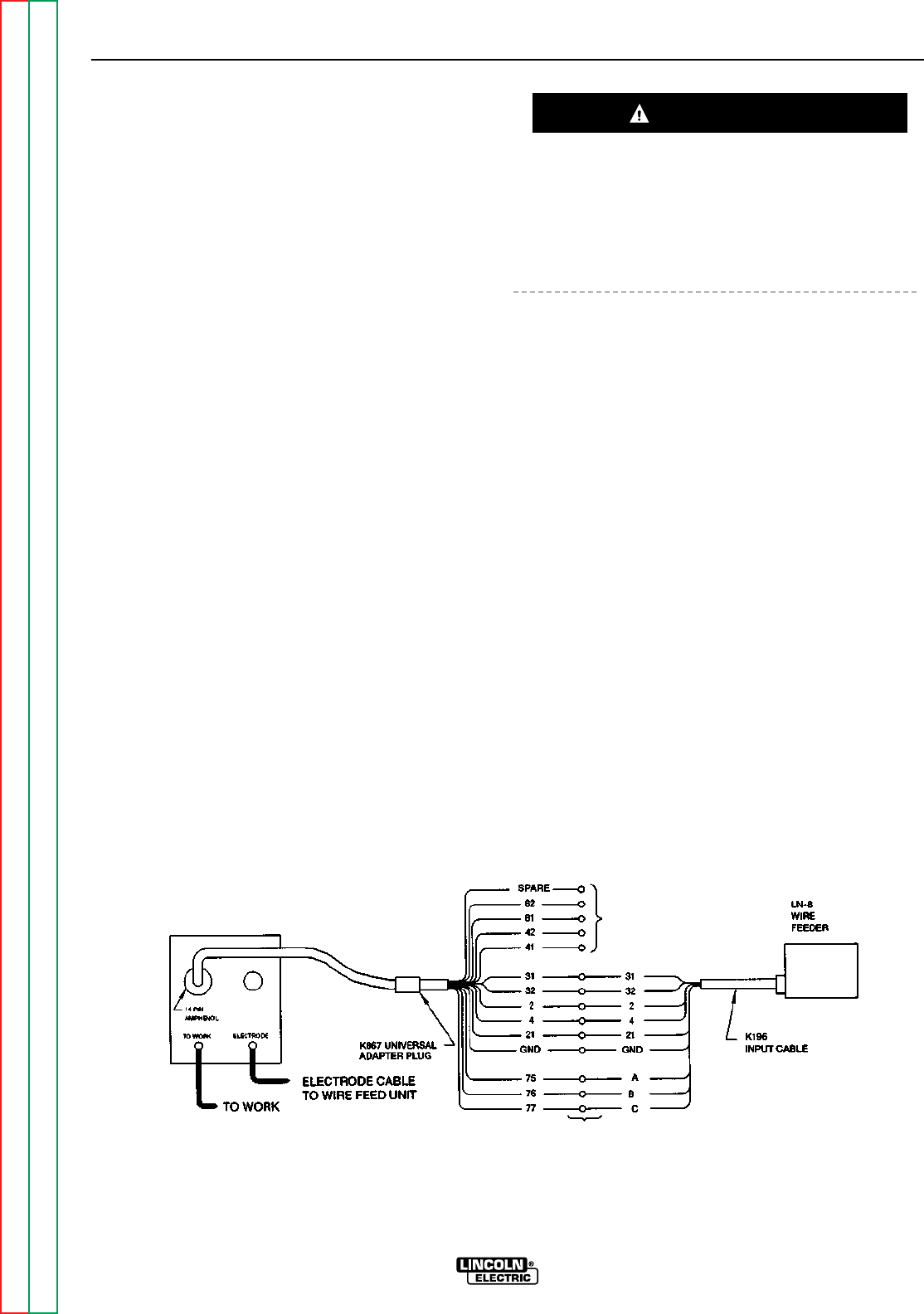

CONNECTION OF THE LN-8 TO THE

RANGER 9 (SEE FIGURE C.6.)

1. Shut the welder off.

2. Connect the electrode cable from the LN-8 to the

“ELECTRODE” terminal of the welder. Connect the

work cable to the “TO WORK” terminal of the

welder.

NOTE: Welding cable must be sized for current and

duty cycle of application.

3. Connect the K867 Universal adapter to the LN-8

wire feeder and the 14 pin amphenol of the

RANGER 9 as indicated in Figure C.6. Make the

proper connections for local or remote control

according to Figure C.6 and the following NOTES,

indicated on the figure:

A. Insulate each unused lead individually.

B. Splice the leads and insulate.

4. Set the welder “polarity” switch to the desired

polarity, either DC (-) or DC (+).

5. Set the “RANGE” switch to the “WIRE FEED” posi-

tion.

6. Place the “IDLER” switch in the “˙HIGH” position.

Any increase of the high idle engine RPM by changing

the governor setting or overriding the throttle linkage

will cause an increase in the AC auxiliary voltage. If

this voltage goes over 140 volts, wire feeder control

circuits may be damaged. The engine governor set-

ting is preset at the factory — do not adjust above

RPM specifications listed in this manual.

7. Place the WELDING TERMINALS switch in the

“REMOTELY CONTROLLED” position.

8. Adjust wire feed speed at the LN-8 and set the

welding voltage with the output “CONTROL” to a

CV (constant voltage) position at the welder.

NOTE: If optional remote control is ued, place the

output control switch in the “CONTROL

REMOTE” position.

FIGURE C.6

RANGER 9/LN-8 CONNECTION DIAGRAM

CAUTION

A

B