SAFETY PRECAUTIONS

• Have qualified personnel do all maintenance and

troubleshooting work.

• Turn the engine off before working inside the

machine.

• Remove guards only when necessary to perform

maintenance and replace them when the mainte-

nance requiring their removal is complete.

• If guards are missing from the machine, get replace-

ments from a Lincoln Distributor. See the EXPLOD-

ED VIEW AND PARTS LIST at the back of this man-

ual.

Read the Safety Precautions in the front of this manu-

al and in the instruction manual for the Onan gasoline

engine used with your machine before working on the

RANGER 9.

Keep all equipment safety guards, covers, and devices

in position and in good repair. Keep your hands, hair,

clothing, and tools away from the recoil housing, fans,

and all other moving parts when starting, operating, or

repairing this machine.

ROUTINE AND PERIODIC

MAINTENANCE

ENGINE MAINTENANCE

To prevent the engine from accidentally starting, dis-

connect the spark plug lead before servicing the

engine.

See Table D.2 for a summary of maintenance intervals

for the items listed below. Follow either the hourly or

the calendar intervals, whichever come first. More fre-

quent service may be required, depending on your

specific application and operating conditions. Table

D.3 shows engine maintenance replacement parts and

numbers.

OIL: Check the oil level after every 5

hours of operation or daily. BE SURE

TO MAINTAIN THE OIL LEVEL.

Change the oil the first time after 25 hours of opera-

tion. Then, under normal operating conditions,

change the oil as specified in Table D.3. If the engine

is operated under heavy load or in high ambient tem-

peratures, change the oil more frequently.

CHANGE THE OIL

Change the oil, while the engine is still warm, as fol-

lows:

1. Drain the oil from the drain plug located on the

engine bottom, as shown in Figure D.1. For the

RANGER 9, a short pipe nipple has been installed

to extend the drain plug access for easier service-

ability.

2. Replace the cap on the drain extension and tighten

it securely.

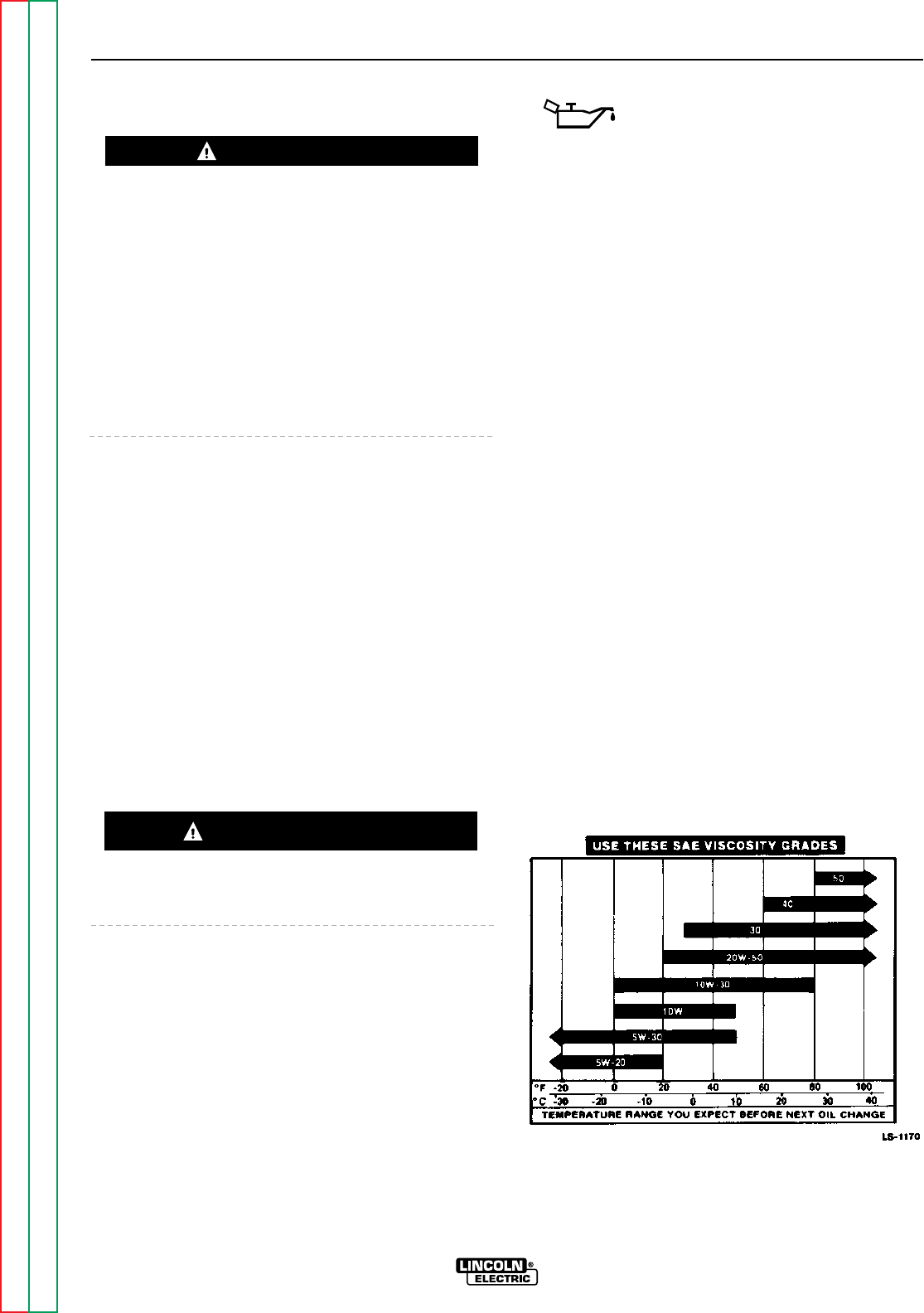

3. Remove the oil fill cap and add oil until the level

reaches the full mark on the dipstick. Use high

quality detergent oil of API service class SF, SF/CC,

or SF/CD . See Table D.1 for recommended vis-

cosity grades. Straight weight oils are recom-

mended for severe duty use and at temperatures

above 32°F (0°C) for minimum oil consumption.

Always check the level with the dipstick before

adding more oil.

4. Reinstall the oil fill cap and dipstick.

TABLE D.1

RECOMMENDED OIL VISCOSITY GRADES

MAINTENANCE

D-2 D-2

RANGER 9 RANGER 9

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

WARNING

CAUTION