To Use the RANGER 9 for AC/DC TIG

(Constant Current) Welding:

1. Connect the K930-1 TIG Module to the RANGER

9. Follow the installation instructions provided

with the kit. Also be sure to follow the special

machine grounding instructions given in the man-

ual.

2. Refer to the instruction manual with the TIG mod-

ule (IM 528) for operation with a RANGER 9 and

proper machine settings.

3. Set the OUTPUT RANGE dial to the appropriate

setting for the electrode you are using. Refer to

IM -528 with the TIG module or refer to Table B.2

for AC TIG welding.

4. Set the POLARITY SWITCH to the desired polarity.

5. Do not AC TIG weld on the 250 AC range setting.

The output current may exceed the rating of the

RANGER 9.

6. Start the arc and begin welding.

NOTE: When using the RANGER 9 for AC TIG weld-

ing of aluminum, the TIG Module is to be set

for CONTINUOUS HF.

After you finish welding:

1. Stop the gasoline engine. See ENGINE OPERA-

TION in this section of the manual.

2. Allow the electrode and work to cool completely.

3. Remove the work clamp from the work.

OPERATION

B-11 B-11

RANGER 9 RANGER 9

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

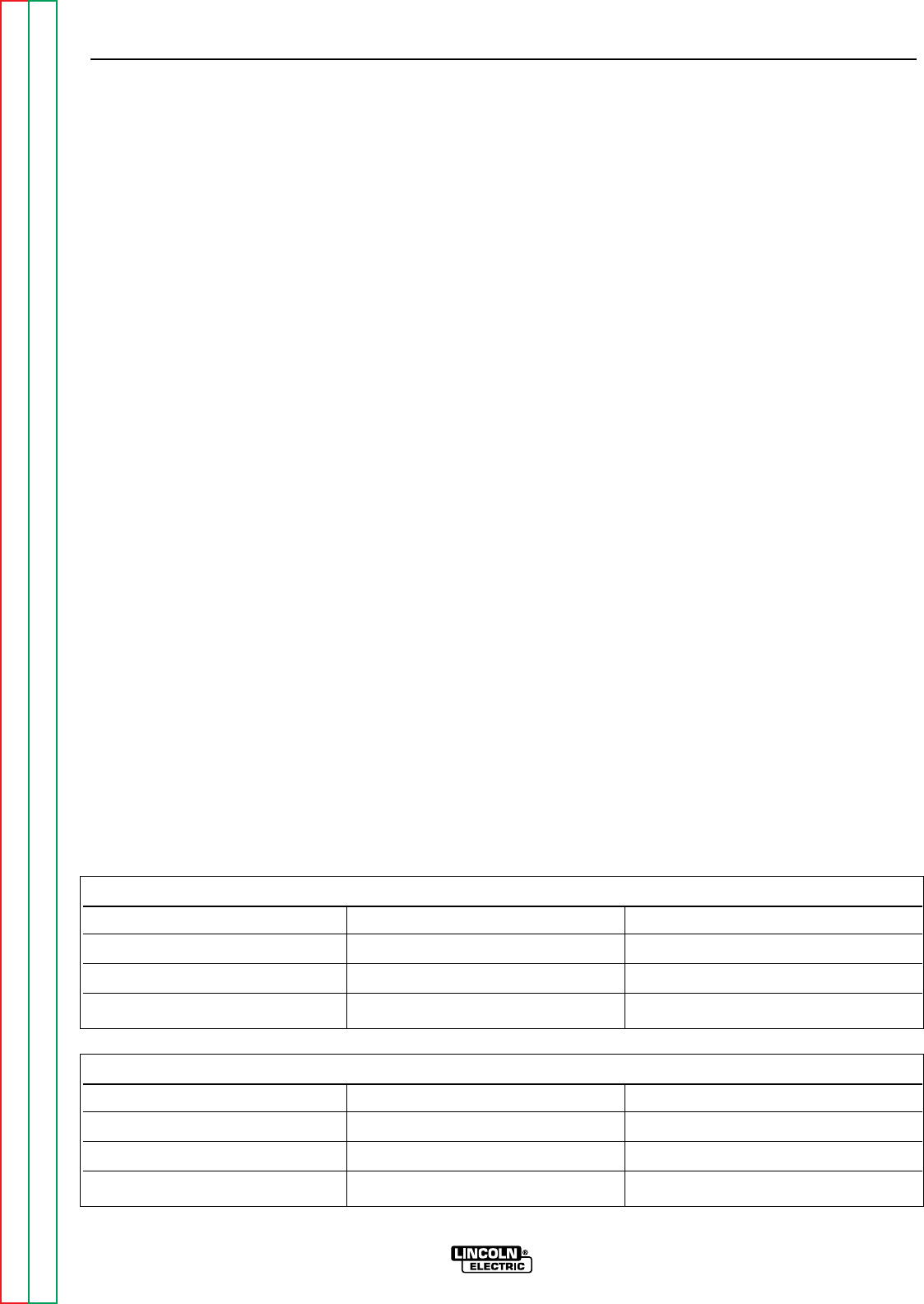

TABLE B.2 - AC TIG WELDING – TIG ELECTRODE/RANGE SETTINGS

Settings for Pure Tungsten

Tungsten Diameter (inches) Range Switch Settings Appropriate Current Range

1/8 90 or 120 160 - 200 Amps

3/32 45 or 90 45 - 140 Amps

1/16 45 or 90 45 - 100 Amps

Settings for 1% Thoriated Tungsten

Tungsten Diameter (inches) Range Switch Settings Appropriate Current Range

1/8 90, 120, or 180 160 - 250 Amps

3/32 45, 90, or 120 100 - 180 Amps

1/16 45 or 90 60 - 120 Amps