7 - 12

7 Selection

MITSUBISHI CNC

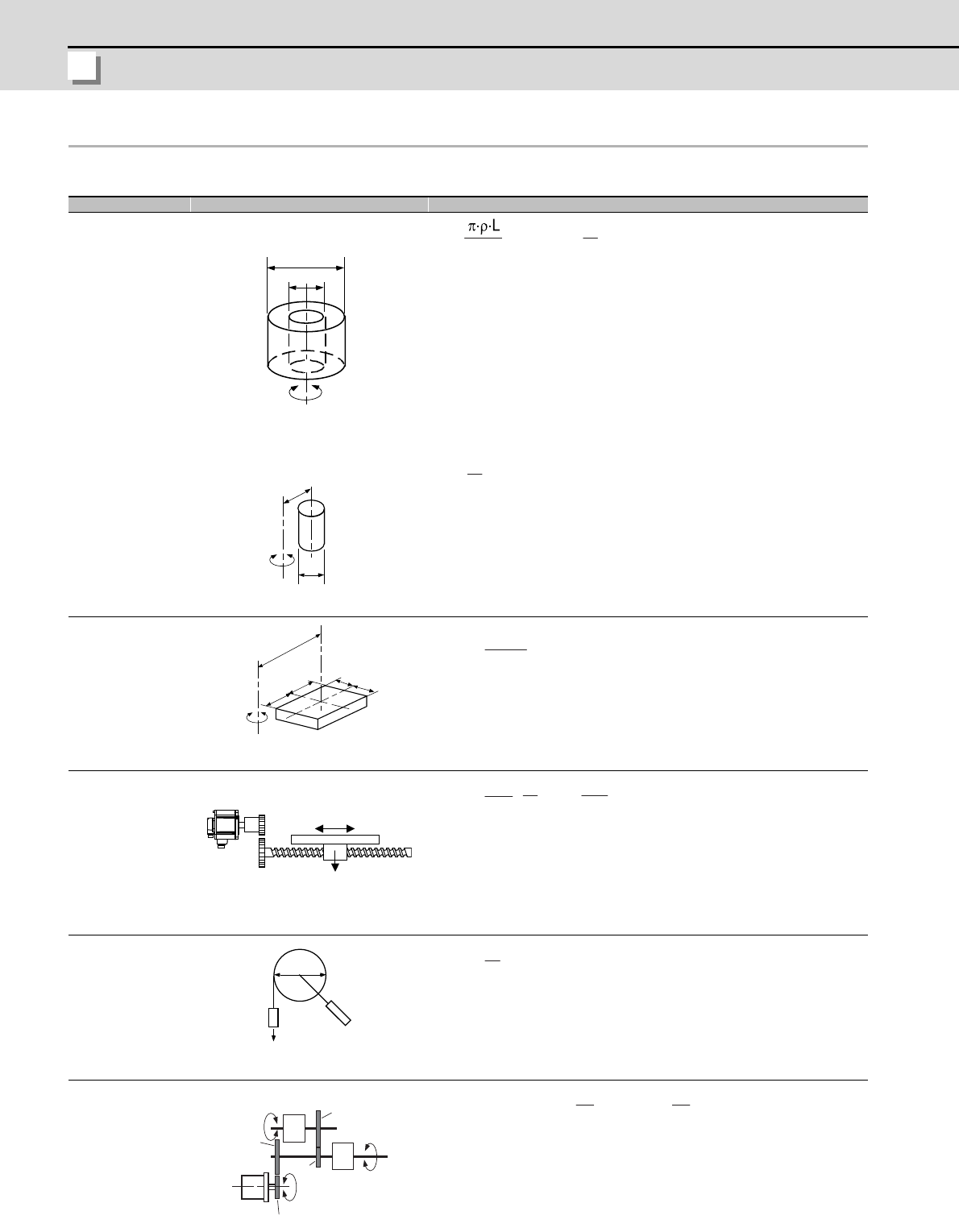

7-1-4 Expressions for load inertia calculation

The calculation method for a representative load inertia is shown.

Type Mechanism Calculation expression

Cylinder

T

L

:Load inertia(kg•cm

2

)

ρ: Density of cylinder material(kg/cm

3

)

L:Length of cylinder(cm)

D

1

:Outer diameter of cylinder(cm)

D

2

:Inner diameter of cylinder(cm)

W:Mass of cylinder(kg)

<Reference data(Material densities)>

Iron:7.80×10

-3

(kg/cm

3

) Aluminum:2.70×10

-3

(kg/cm

3

)

Copper:8.96×10

-3

(kg/cm

3

)

J

L

:Load inertia(kg•cm

2

)

W:Mass of cylinder(kg)

D:Outer diameter of cylinder(cm)

R:Distance between rotary axis and cylinder axis(cm)

Column

J

L

: Load inertia(kg•cm

2

)

W:Mass of cylinder(kg)

a,b,R:Left diagram(cm)

Object that moves

linearly

J

L

:Load inertia(kg•cm

2

)

W:Mass of object that moves linearly(kg)

N:Motor speed(r/min)

V:Speed of object that moves linearly(mm/min)

ΔS:Object movement amount per motor rotation(mm)

Suspended object

J

L

:Load inertia(kg•cm

2

)

W:Object mass(kg)

D:Diameter of pulley(cm)

Jp:Inertia of pulley(kg•cm

2

)

Converted load

J

L

:Load inertia(kg•cm

2

)

J

A

,J

B

:Inertia of load A, B(kg•cm

2

)

J

11

~J

31

:Inertia(kg•cm

2

)

N

1

~N

3

:Each shaft’s speed(r/min)

ǾD

1.

ǾD

2.

Rotary shaft is cylinder center

Rotary shaft

J

L

=

.

(D

1

4

-D2

4

) =

.

(D1

2

D2

2

)

9

R

D

When rotary shaft and cylinder

shaft are deviated

Rotary shaft

J

L

=

.

(D

2

+8R

2

)

8

W

R

a

a

b

b

Rotary shaft

JL = W(

+R

2

)

a

2

+b

2

W

V

N

Servo

motor

J

L

= W(

.

)

2

= W( )

2

10

1

V

ΔS

2πN

20π

D

W

J

L

= W(

)

2

+J

p

D

2

N

2

J

A

J

B

N

3

J

31

N

1

N

1

J

11

J

22

J

21

Load A

Servo

motor

Load B

J

L

= J

11

+(J

21

+J

22

+J

A

)

.

(

)

2

+

(J

+J

B

)

.

(

)

2

N1

N2

N1

N3