Section VIII - Power$ync II

™

Operation

Quincy Compressor

®

- QSD™ 35

The third consideration is the nature of air consumption

within the system itself. A system that is subject to

rapid, cyclic air consumption may require a wider

differential than one that has a steady air requirement. As

with the other considerations, improvements in energy

efficiency can be obtained by adjusting the pressure

settings to maintain the lowest acceptable steady

pressure.

NOTE

Cycling more frequently than six times a minute

may cause a high temperature condition that may

result in a shutdown.

Power$ync II

™

is factory set to operate efficiently for

most compressed air systems. It has pressure limits based

on its particular configuration. Use the factory setting for

a while before making any changes. When making

changes, document the change and the resulting system

pressure and fluctuation. Documenting the changes and

results will allow the compressor to be fine-tuned for a

particular application.

Network Installation

Power$ync II

™

compressors need to be wired together to

form a network that will take advantage of the

sophisticated multiple machine control capability built

into the software. To do this, you will need the

following:

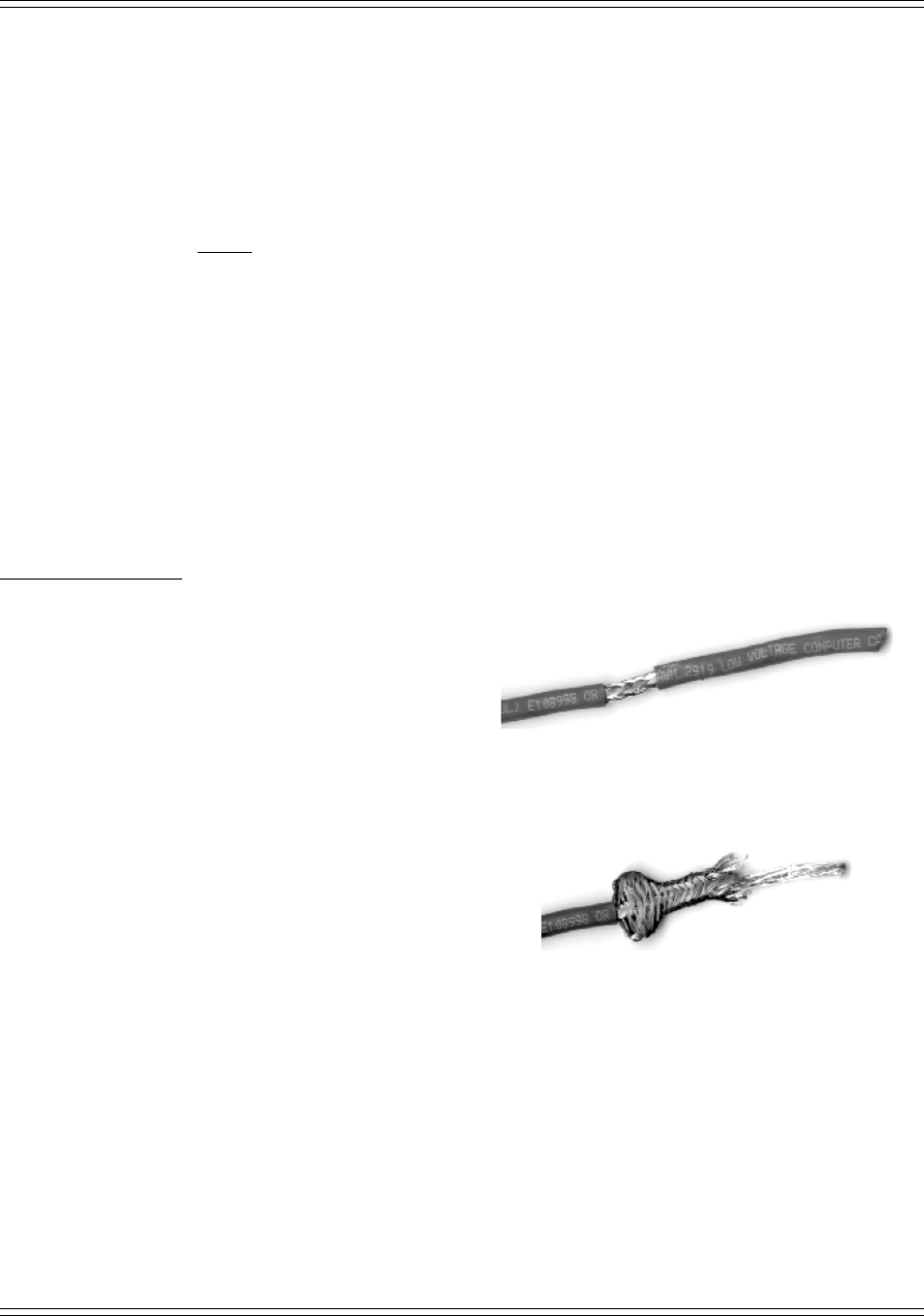

1) A three-wire cable (Quincy part number 141234-01,

-02 or -03 communications cable).

2) One cable terminator box (Quincy part number

140715).

3) Conduit is required for NEMA 4 applications and

strongly recommended for all other applications.

The maximum total cable length from the terminator box,

through each compressor in the network and to the last

compressor in line must be less than 600'.

Connecting Cable to the Power$ync II

™

Circuit Board

The first machine in the network will have one cable

coming out of the Power$ync II

™

control enclosure. All

other machines on the network will have one cable in and

one cable out. The outbound cable on the last machine

will be connected to the terminator box which must have

access to a 110-volt electrical outlet. No cable ends or

crimping tools are required to complete the installation.

1) On the first machine in the network, open the

Power$ync II

™

control panel by removing the five

screws on the face. Tilt the hinged face down to

expose the circuit boards and power supply inside.

2) Remove one of the hole plugs on the back of the

control enclosure. Insert the end of the

communications cable and bring it to the far right,

lower corner of the enclosure. Make certain that

there are a few inches of extra length at this point.

3) Remove 1.5" of the outer insulating cover. Carefully

retract the braided wire shielding to expose the bare

ground wire and the foil cover for the two insulated

wires.

4) Remove excess braided wire shielding, being careful

not to damage the ground wire.