29

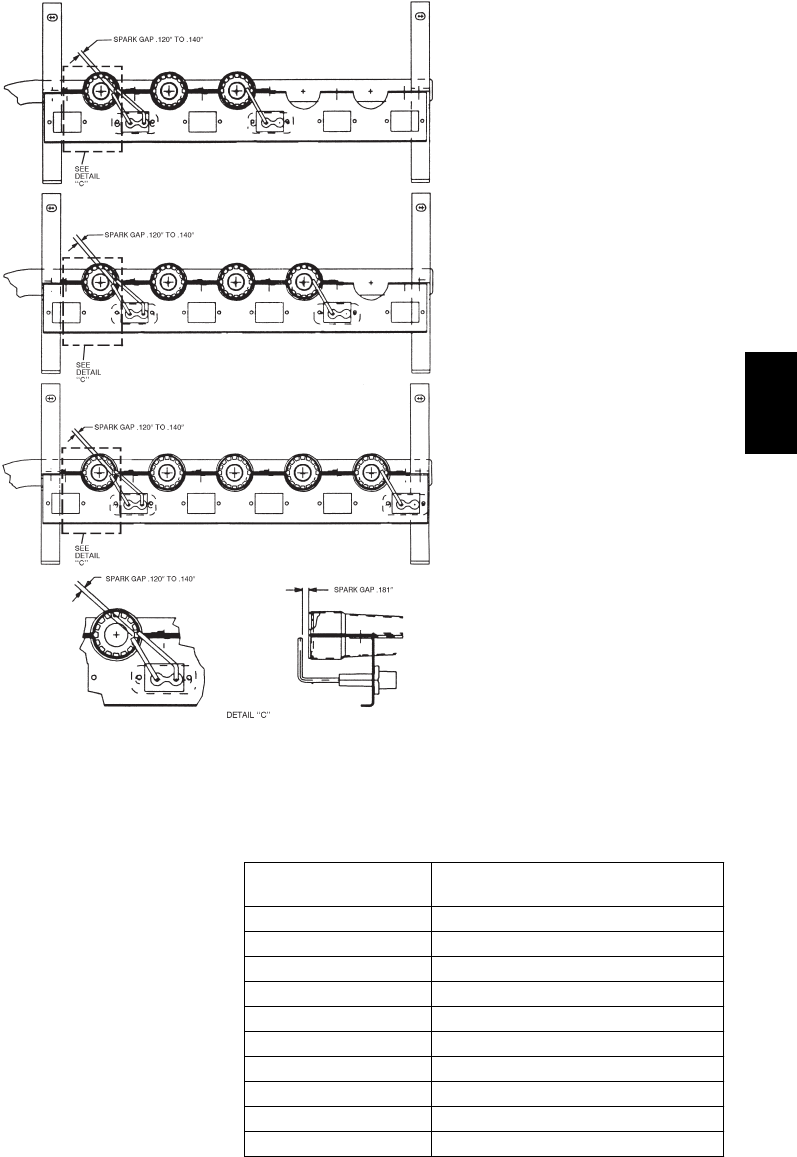

125,000/90,000 BTUH INPUT

180,000/120,000 BTUH INPUT

240,000/180,000 BTUH INPUT

250,000/200,000 BTUH INPUT

C08447

Fig. 38 -- Spark Adjustment (08--14)

Burner Ignitio n

Unit is equipped with a direct spark ignition 100% lockout

system. Integrated Gas Unit Controller (IGC) is located in

the c ontrol box. (See Fig. 37.) The IGC contains a

self--diagnostic LED (light--emitting diode). A single LED

on the I GC provides a visual display of operational or

sequential problems when the power supply is

uninterrupted. (See Fig. 40.) When a break i n power

occurs, the IGC will be reset (resulting in a loss of fault

history) and the indoor (evaporator) fan ON/OFF times

will be reset. The L ED error code can be observed

through the viewport. During servicing refer t o the label

on the control box cover or Table 9 for an explanation of

LED error code descriptions.

If loc kout occurs, unit may be reset by interrupting power

supply to unit for at least 5 seconds.

Table 9 – LED Error Cod e Descriptio n*

LED INDICATION

ERROR CODE

DESCRIPTION

ON Normal Operation

OFF Hardware Failure

2Flashes Limit Switch Fault

3Flashes Flame Sense F ault

4Flashes 4 Consecutive Limit Switch Faults

5Flashes Ignition Lockout Fault

6Flashes Induced---Draft M otor Fault

7Flashes Rollout Switch Fault

8Flashes Internal Control Fault

9Flashes Software Lockout

LEGEND

LED --- Light Emitting Diode

* A 3 – second pause exists between LED error code fl ashes. If

more than one error code exists, all applicable codes will be

displayed in numerical sequence.

IMPORTANT: Refer to Troubleshooting Table 13 and 14

for additiona l i nformation.

580J