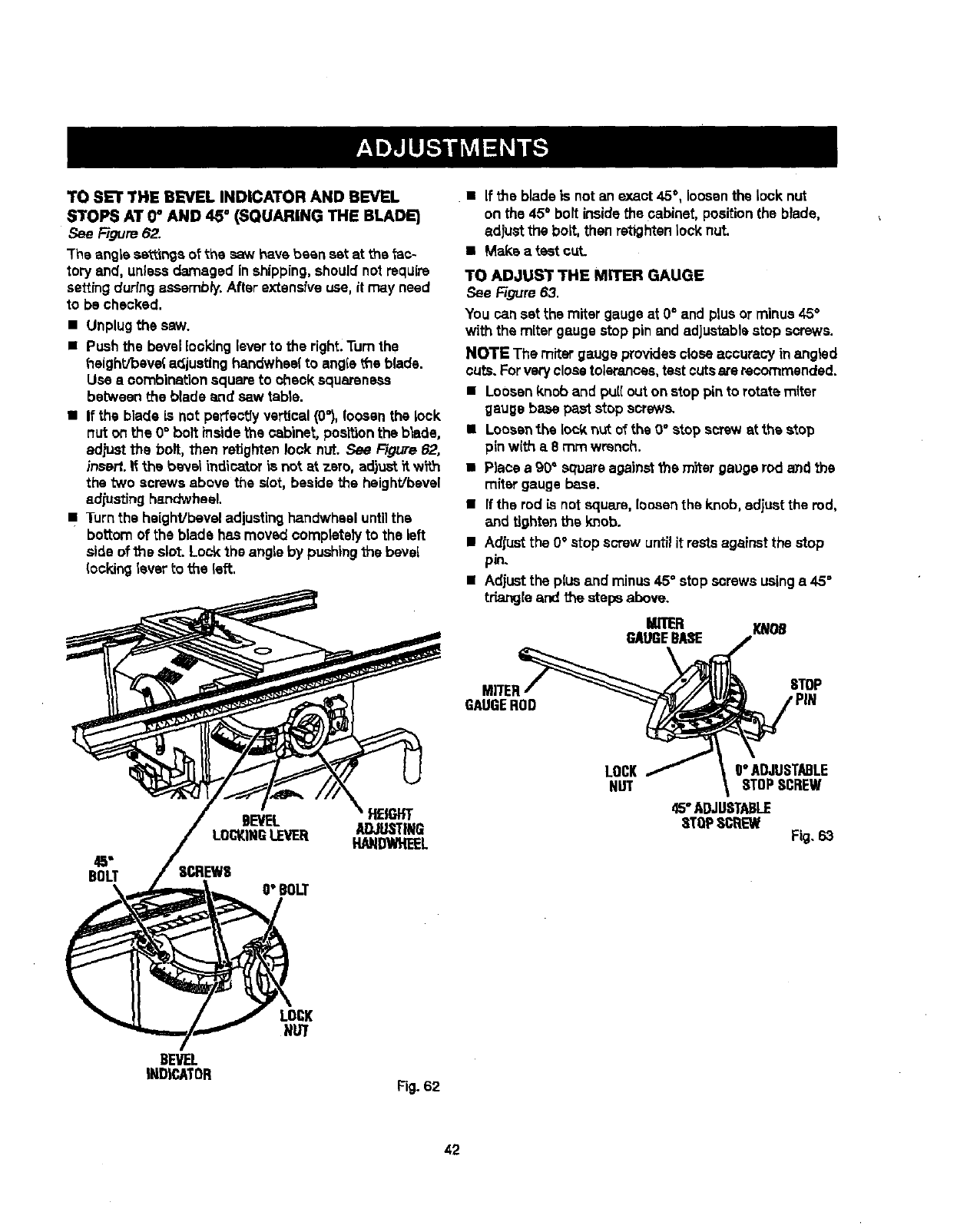

TO SET THE B_VEL INDICATOR AND BEVEL

STOPS AT 0_ AND 45 ° (SQUARING THE BLADE)

Figure62.

The angle sa_mgs oFthe saw havebeen set at the _ac-

tory and, unlessdamaged inshipping,shouldnot require

settingduringassembly. After extensive use, itmay need

to be checked.

• Unplugthe saw.

• Pushthe bevellooking leverto the right.Turnthe

t_eight/beve{ adjustinghandwhsel to angleL'heblade.

Use • combinationsquareto check squareness

between theblade and saw table.

• If the blade is not perfectlyvertical(0_),loosenthe lock

nut on the 0° bolt _nsidethe cabinet, positionthe blade,

adjustthe bolt, then retightenlock nut. See Figure62,

insall, if the banal indicatoris not at zero, adjust_tw_.h

the "twoscrews above the slot, besidethe heighVbevel

adjusting handwheel.

• Turn theheighVbeveladjustingha.ndwhesluntilthe

bottom of the blade has moved completelyto theleft

side ofthe slot. Lock the angleby pushing the bevel

_ockinglever to the left.

BOLT

BEVEL HEIGHT

ADJUSTING

LOCKINGLEVEE[ HANDWHEEL

O"BOLT

BEVEL

INDICATOR

LOCK

NUT

Fig. 62

• Ifthe bladeis not anexact 45°, loosenthe lock nut

on the 45° boltinsidethecabinet, positionthe blade,

adjustthe bolt, then retighten lock nut.

• Make a test cut.

TO ADJUST THE MITER GAUGE

See Figure63.

You can setthe miter gaugeat O° and plusor minus45°

with the mitergaugestop pin andadjustablestop screws.

NOTE The miter gaugeprovidescloseaccuracy inangled

cuts.Forveryclosetolerances,testcutsarerecommended.

• Loosenknoband pull out on stoppin torotate miter

gaugebasepaststop screws.

• Loosenthe lockn_t ofthe 0° stop screwst the stop

pinwith a 8 rnmwrench.

• Place a 90" squareagainstthe m_ar gaugerodand the

miter gauge base.

• Ifthe rod isnotsquare, loosenthe knob, adjustthe rod,

and tightenthe knob.

• Adjustthe 0°atop screw untilitrestsagainstthe stop

pin.

• Adjustthe plusend minus 45° stop screwsusinga 45°

triangle and the stepsabove.

MITER

GAUGEBASE

MITER_

GAUGEROD

LOCK/

NUT

m

O"ADJUSTABLE

STOPSCREW

45"ADJUSTABLE

STOPSCREW

Fig. 63

42