12

ENGLISH

Installation

1. The machine is heavy. Carefully lift

it out of its shipping carton with the

help of another person.

(The manufacturer recommends

that you keep the shipping carton

and all packing materials in case the

machine needs to be

shipped for

service or repair. If you discard the

packing materials, do so in observ-

ance of and in compliance with all

environmental laws, rules and regu-

lations regarding disposal and recy-

cling that apply at y

our site.)

3

Note:

Do not install rubber feet if the

machine is going to be mounted on the

optional machine stand. The machine

stand is not included in standard deliv-

ery, but can be purchased separately.

For more information, see chapter 11.

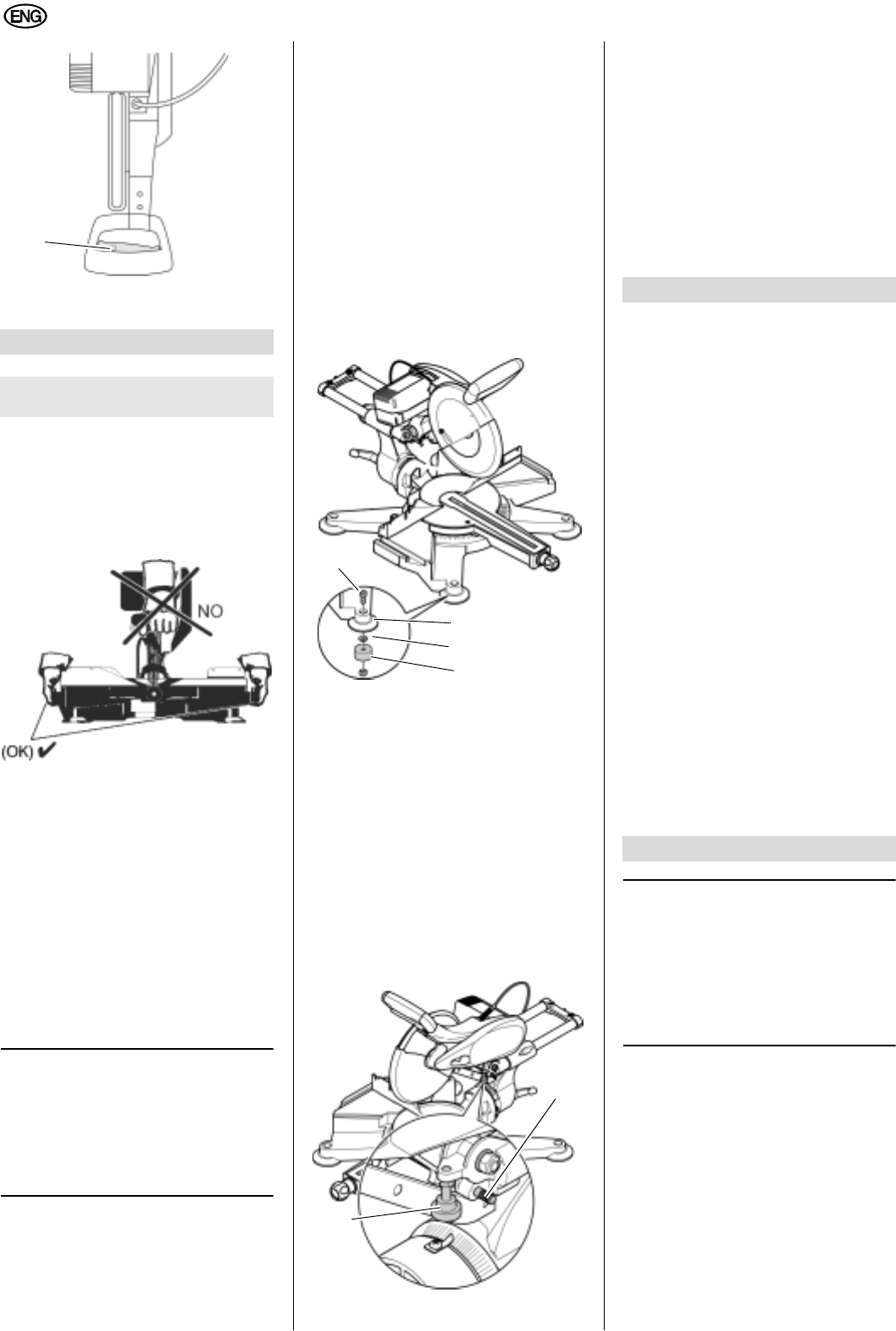

2. Turn the machine over to install the

rubber feet:

The feet must be accessible from

all directions.

Before proceeding, be sure that

the machine is standing firmly in

place even while ti

pped over.

3. Fit the nut (36) into the hole on the

bottom of the rubber foot.

4. Insert the Allen head screw (33) into

the machine’s foot from the top. Fit

the washer (34) on the screw (33)

and attach the rubber foot (35) with

the previously inserted nut (36) to

the screw (33) by hand and start to

tighten.

5. To do so hold the screw (33) with

the 6mm Allen wrench.

6. Hand tighten only!

7. Place the machine on a flat and

sturdy surface, large enough to

allow for all necessary movements

and adjustments.

All four feet must firmly rest on

the base.

The ideal height for the base is

32 inches.

The machine must remain stable,

in particular when cutting work

pieces which could cause it to tip.

8. Push the sawhead assembly slightly

down and pull the transport locking

pin (37) out.

Transport

1. The transport lock

ing pin (37) must

be inserted for transport.

2. Depending on what kinds of cuts

were made previosuly, it may be

necessary to adjust the limit screw

(38) for the adjustment of the cutting

depth. This allows th

e saw head to

be fully lowered, after which the

transport locking pin (37) can then

be inserted.

96q cutting angle range for bevel

cuts (48q left through 48q right) with

five preset stops.

110q cuttin

g angle range for miter

cuts (50q left through 60q right) with

ten preset stops.

Soft start.

Cutting depth adjustment for making

grooves with integrated limit screw.

Easy mobility due to lightweight

con-

struction.

Precise and sturdy die-cast alumin-

ium construction.

TCT saw blade.

Easy saw blade change. The saw

blade can be held with the saw

blade lock. No disassembly of the

protective devices required.

Maximum cutting depth

3 3/16".

Maximum cutting width 11 1/4".

Ergonomic and easy for both left-

handed and right-handed operation.

Installation of auxiliary fence possi-

ble.

3

Note:

In this chapter the essential oper-

ating elements of the machine are intro-

duced.

The proper use of the machine is

described in chapter 8, "Operation".

Read this chapter in its entirety before

using the saw for the first time.

ON/OFF switch

x To turn the motor on, press and hold

the ON/OFF switch (3 9) in the han-

dle. To stop the motor, release the

ON/OFF switch.

4. Installation and transport

A CAUTION

Do not carry the machine by the

handle; the handle is not designed

to bear the weight of the entire

machine. When carrying the

machine, hold it on both sides of

the base.

32

33

34

35

36

37

38

5. Special Product Features

6. Machine Details