17

ENGLISH

piece is cut at an angle other than 90° to

the fence and material surface.

For compound miter cuts the maximum

dimensions of the work pieces depends

on both cutting angles - the angle of the

rotating table and the tilt angle of the

sawhead. These are s

hown in the table

below.

Starting position:

Sawhead assembly fully raised.

Cutting depth limit screw set to max-

imum depth. Limit screw is securely

tightened.

Rotating table locked in desired

position.

Sawhead tilted to desired angle

against the work piece's surface and

locked.

If the sawhead assembly is tilted

between 22.5° and 48° to the right:

loosen the Phillips head screw and

swing the hinged fence to the rear.

Lock screw of t

he track arm loos-

ened.

Track arm not extended.

Cutting the work piece:

1. Hold the work piece against the

fence.

2. Press and hold the ON/OFF switch .

3. Slowly swing the sawhead assembly

all the way down, holding t

he handle

firmly. When sawing exert only mod-

erate pressure. This keeps the

motor speed from dropping.

4. For wider work pieces pull sawhead

assembly forward (towards the

operator).

5. Cut work piece in a single pass.

6. Release the ON/OFF switch and let

the sawhead slowly return to its

upper starting position.

3

Note:

Crown moulding can be cut with

the back on the saw ta ble and the top

edge against the fence.

For cutting crown moulding the following

settings apply:

8.5 Making Grooves

3

Note:

During groove cutting only a par-

tial cut, up to a certain depth, is made in

the work piece. This operation is made

possible by use of the track arm, which

allows the sawhead assembly to move

horizontally over

the work piece and the

limit screw, which allows for adjustment

of a given cutting depth.

Starting position:

Sawhead assembly fully raised.

Sawhead tilted to desired angle

against the work piece's surface and

locked.

Rotating table locked in desired

position.

Lock screw of the track arm loos-

ened.

Track arm not extended.

Cutting the work piece:

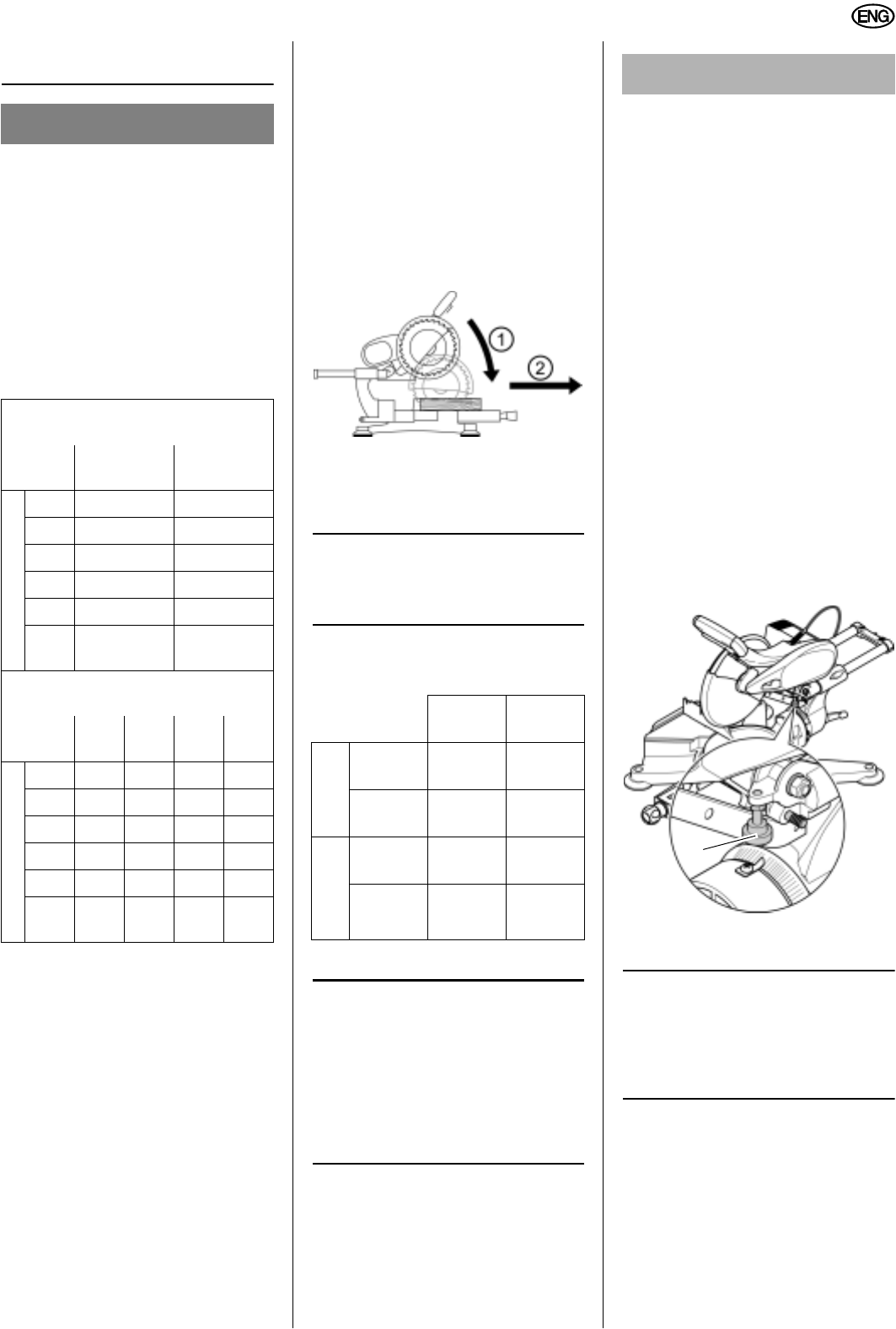

1. Adjust the cutting depth limit screw

(51) to the desired depth for the

groove and then tighten it securely.

2. Hold the work piece against the

fence.

3

Note:

For the groove to be cut at the

desired depth across the whole work

piece width, a suitable spacer strip

needs to be placed between the work

piece and the fence.

3. Press and hold the ON/OFF switch .

4. Slowly swing the sawhead assembly

fully down, holding the handle firmly.

When sawing exert only moderate

pressure, to prevent the motor

speed

to drop too much.

5. When sawing, pull sawhead assem-

bly forward (towards the operator).

A DANGER

When making compound miter cuts

the saw blade is much more exposed

than during normal cuts and so the

risk of injury increases. Always stay

a sufficiently safe distance away

from the saw blade.

Work piece width (in.) with sawhead

assembly tilted approximately

22.5°

left and right

48 °

left and right

Rotating table position

15° 10 13/16 10 13/16

22.5° 10 1/4 10 1/4

30° 9 5/8 9 5/8

45° 7 7/8 7 7/8

50° 7 1/16 7 1/16

60 °

right

5 1/2 5 1/2

Work piece width (in.) with sawhead

assembly tilted approximately

22.5°

left

22.5°

right

48 °

left

48 °

right

Rotating table position

15° 2 3/4 2 9/16 1 3/4 13/16

22.5° 2 3/4 2 9/16 1 3/4 13/16

30° 2 3/4 2 9/16 1 3/4 13/16

45° 2 3/4 2 9/16 1 3/4 13/16

50° 2 3/4 2 9/16 1 3/4 13/16

60 °

right

2 3/4 2 9/16 1 3/4 13/16

Sawhead

tilt

Miter angle

Inside corner

Left

side

33.9°

left

31.6°

right

Right

side

33.9°

right

31.6°

left

Outside corner

Left

side

33.9°

right

31.6°

left

Right

side

33.9°

left

31.6°

right

A WARNING

During the groove cutting operation

it is especially important no lateral

pressure is applied to the saw blade.

Otherwise the sawhead may be

kicked up abruptly! Always use a

clamp to hold the work piece in

place when making grooves. Avoid

lateral pressure on the sawhead.

Make sure that the work piece lies

flat and does not jam.

51