20

ENGLISH

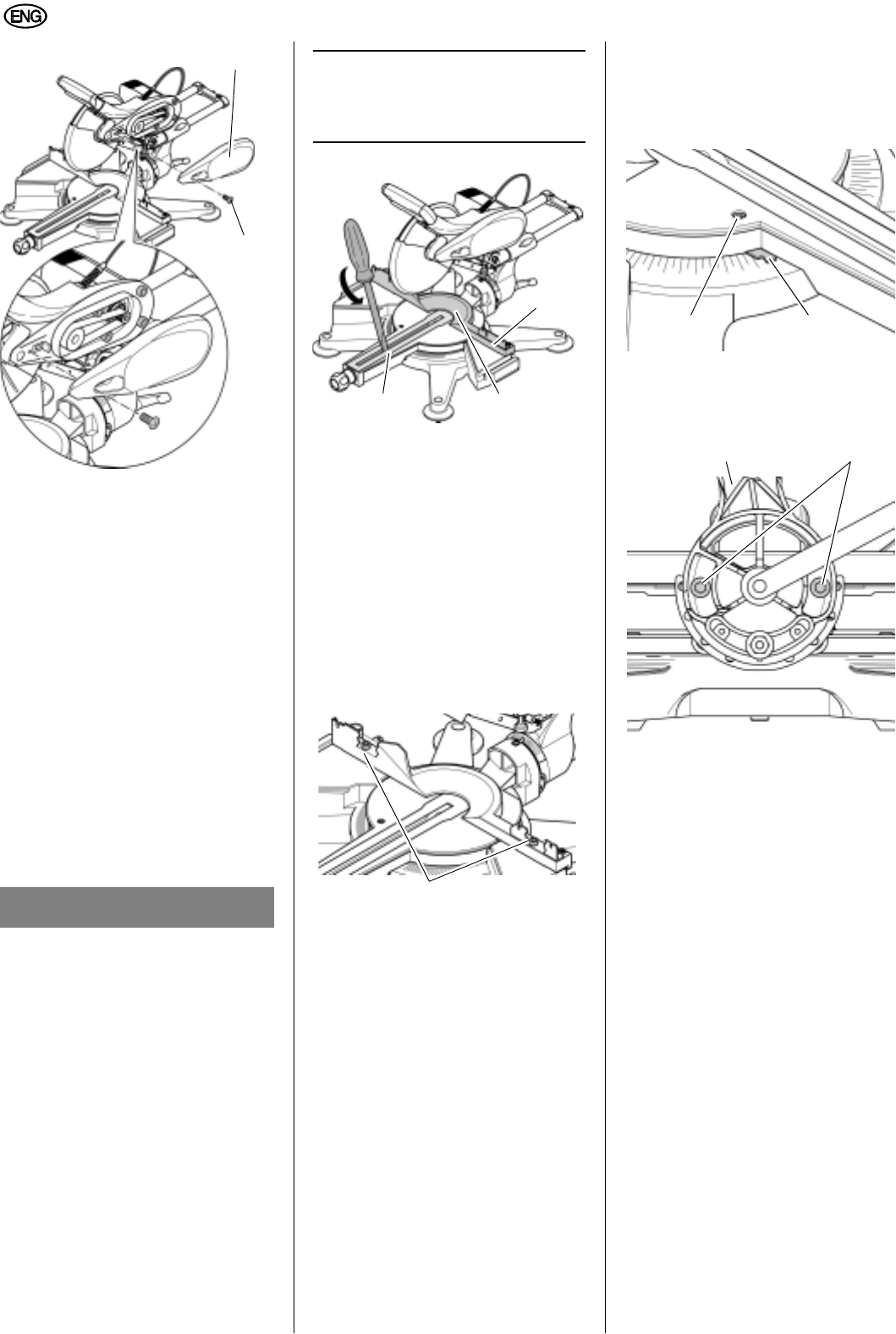

2. Check the drive belt with your

thumb. If the drive belt needs to be

tightened (more than 1/8" play) or if

it needs to be replaced because of

visible wear, tear or cracking:

Loosen the four metric Allen head

screws by turning each screw

about one turn counterclockwise.

Replace the belt if necessary or

just tighten it by sliding the motor

to the rear until the belt is tight.

Hold the motor in its position and

tighten all four screws by turning

them clockwise until they are

securely tightened.

3. Replace the plastic cover (67) and

secure with the Phillips head screw

(68).

9.3 Kerf Plate Replacement

To replace the kerf plate:

1. Swing the hinged fence down (69).

2. Take the fence (70) off.

3. Loosen the kerf plate (71) by prying

it loose with a screwdriver and then

remove it.

3

Note:

This will destroy the kerf plate

(71). Once removed from the machine, a

kerf plate must never be re-used.

4. Insert the new kerf plate, making

sure it snaps into place.

5. Install the fence (70) and adjust it.

6. Swing the hinged fence (69) up and

secure it.

9.4 Adjustments

Fence adjustment

1. Swing the hinged fence down.

2. Loosen the fastening screws (72) of

the fence.

3. Adjust the fence position with a con-

tractor's square or another appropri-

ate right angle until it is exactly per-

pendicular (90

°) to the saw blade

with the rotating table locked in the

0° position.

4. Tighten the metric Allen head set

screws on the the fence and then

use the square to check your adjust-

ment. If necessary, re

peat the

adjustment procedure.

5. Swing the hinged fence up and

secure it.

Miter angle indicator adjustment

1. Turn the rotating table to one of the

preset stops at the °0, 15°, 22.5°,

30°, 45°, or 60°positions.

2. Loosen the metric Allen head scre

w

(73).

3. Adjust the position of the indicator

(74) until it points exactly to the cor-

responding angle value.

4. Tighten the metric Allen head screw

(73).

Bevel tilt positive stop adjustment

1. Lock the track arm holder (75) in the

0° position.

2.

Loosen the two metric Allen head

screws (76) at the back of the

machine by turning them about one

turn counterclockwise.

3. Use a contractor’s square or

another appropriate right angle and

adjust the track arm

holder until the

saw blade is exactly perpendicular

(90°) to the the rotating table.

4. Tighten the two metric Allen head

screws (76) at the back of the

machine by turning the screws (76)

clockwise until the

angle setting is

secured. Check your adjustment

with the square. If necessary, repeat

the adjustment procedure.

Miter angle indicator adjustment

1. Loosen the Phillips head screw (78).

2. Adjust the position of the indicator

(77) until it points exactly to the cor-

res

ponding angle value, e.g. 0°.

3. Tighten the Phillips head screw (78).

A DANGER

If the kerf plate is damaged, small

parts may become stuck between

kerf plate and the saw blade and

cause the saw blade to jam. Check

the machine for possible damage

before every use. Replace a dam-

aged kerf plate immediately! Use

only OEM parts! Non-OEM parts and/

or parts not specifically approved by

the manufacturer may lead to unfore-

seen damage and possibly result in

personal injuries.

67

68

69

70

71

72

73 74

75 76