15

ENGLISH

8.1 Standard Crosscuts

For standard crosscuts the maximum

dimension (inches) of the work pieces

are:

Starting position:

Transport locking pin pulled out.

Sawhead assembly fully raised.

Cutting depth limit screw set to max-

imum depth. Limit screw is securely

tightened.

Rotating table in 0° position, the lock

screw of the rotating table is

securely tightened.

Sawhead assembly is in vertical (0°)

position, bevel tilt lock lever tight-

ened.

Hinged fence on top of the fence

and secured.

Track arm not extended.

Lock screw of the track arm loos-

ened (only if required, such as when

cutting a wide work piece).

Cutting the work piece:

1. Hold the work piece against the

fence.

2. Press and hold the ON/OFF switch .

3. Slowly swing the sawhead assembly

all the way down, holding the handle

firmly. When sawing exert only mod-

erate pressure. This keeps the

motor speed from dropping.

4. For wider work pieces pull sawhead

assembly forward (towards the

operator).

5. Cut work piece in a single pass.

6. Release the ON/OFF switch and let

the sawhead slowly return to its

upper starting position.

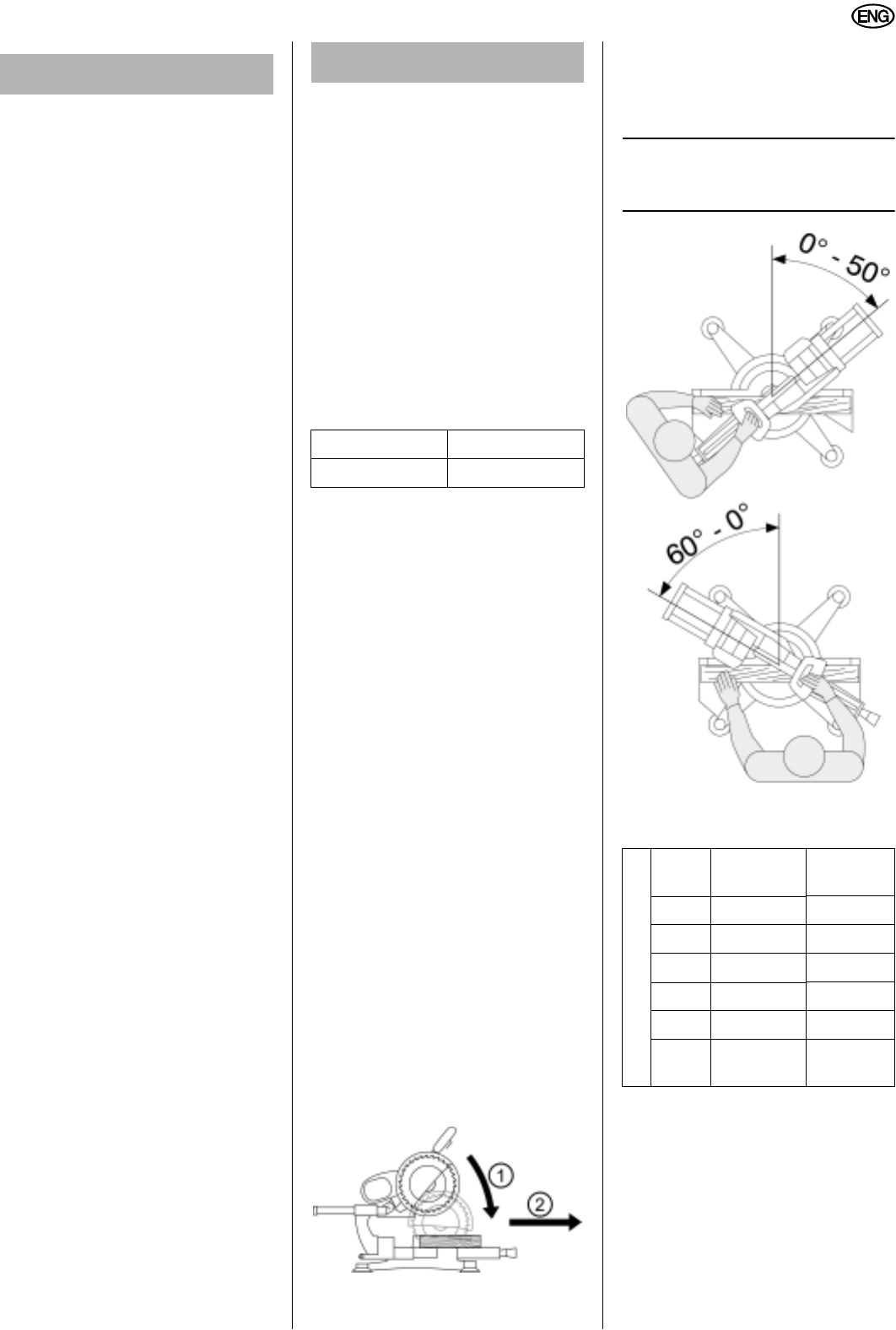

8.2 Miter Cuts

3

Note:

A miter cut cuts the work piece at

an angle to the fence.

The maximum work piece dimensions

for miter cut angles are shown in inches

in the table below:

Starting position:

Sawhead assembly fully raised.

Cutting depth limit screw set to max-

imum depth. Limit screw is securely

tightened.

Sawhead assembly is in vertical (0°)

position, bevel tilt lock lever tight-

ened.

Hinged fence on top of the fence

and secured.

Track arm not extended.

A WARNING

x Use eye protection. Always wear

ANSI approved impact safety

goggles. If you are producing

metal filings or wood chips, wear

a full face shield.

x Use ear protection. Always wear

ANSI approved ear protection

such as ear plugs or ear muffs.

x Use respiratory protection when

working around metal, wood,

especially treated wood, chemi-

cal dusts or mists. Always wear

an ANSI approved dust mask or

respirator or other respiratory

protection in accordance with

current OSHA, MSHA and NIOSH

regulations.

x Wear head protection if required

by your type of work or by regu-

lations applying to the job site.

x Wear protective, electrically non-

conductive clothes and non-skid

foot wear.

x Safeguard your work piece and

secure it against unintended

movement and slipping during

cutting. Use support for long

work pieces which would other-

wise fall off the machine’s rotat-

ing table after the cut. Use the

auxiliary fence for cutting small

pieces.

x If possible, work with a suitable

dust collector connected to the

saw. The dust collector must

comply with the data stated in

chapter 15, entitled "Technical

Specifications".

x Cut only work pieces that have

dimensions which allow them to

be safely and securely held (or

clamped) during cutting.

x Do not jam work pieces.

x Never try to slow the saw blade

down or stop it by pushing the

work piece against the saw

blade from the side.

x Avoid strained body positions

and over-reaching. Assume

proper operating position:

in front of the machine with

body positioned for normal

operation;

directly in front of the saw;

to the side of the machine.

x When tilting the sawhead assem-

bly to the side, hold the sawhead

by the handle and keep your fin-

gers away from the track arm

holder and out of its tilting

range.

x Do not reach under the rotating

table when adjusting the miter

angle.

x After each cutting operation

return the track arm to its rear

starting position.

Width approx.11 7/32

H

eight approx.3 3/16

A WARNING

Rotating table position

Width

approx.

Height

approx.

15° 10 13/16 3 3/16

22.5° 10 1/4 3 3/16

30° 9 5/8 3 3/16

45° 7 7/8 3 3/16

50° 7 1/16 3 3/16

60 °

right

5 1/2 3 3/16