21

ENGLISH

3

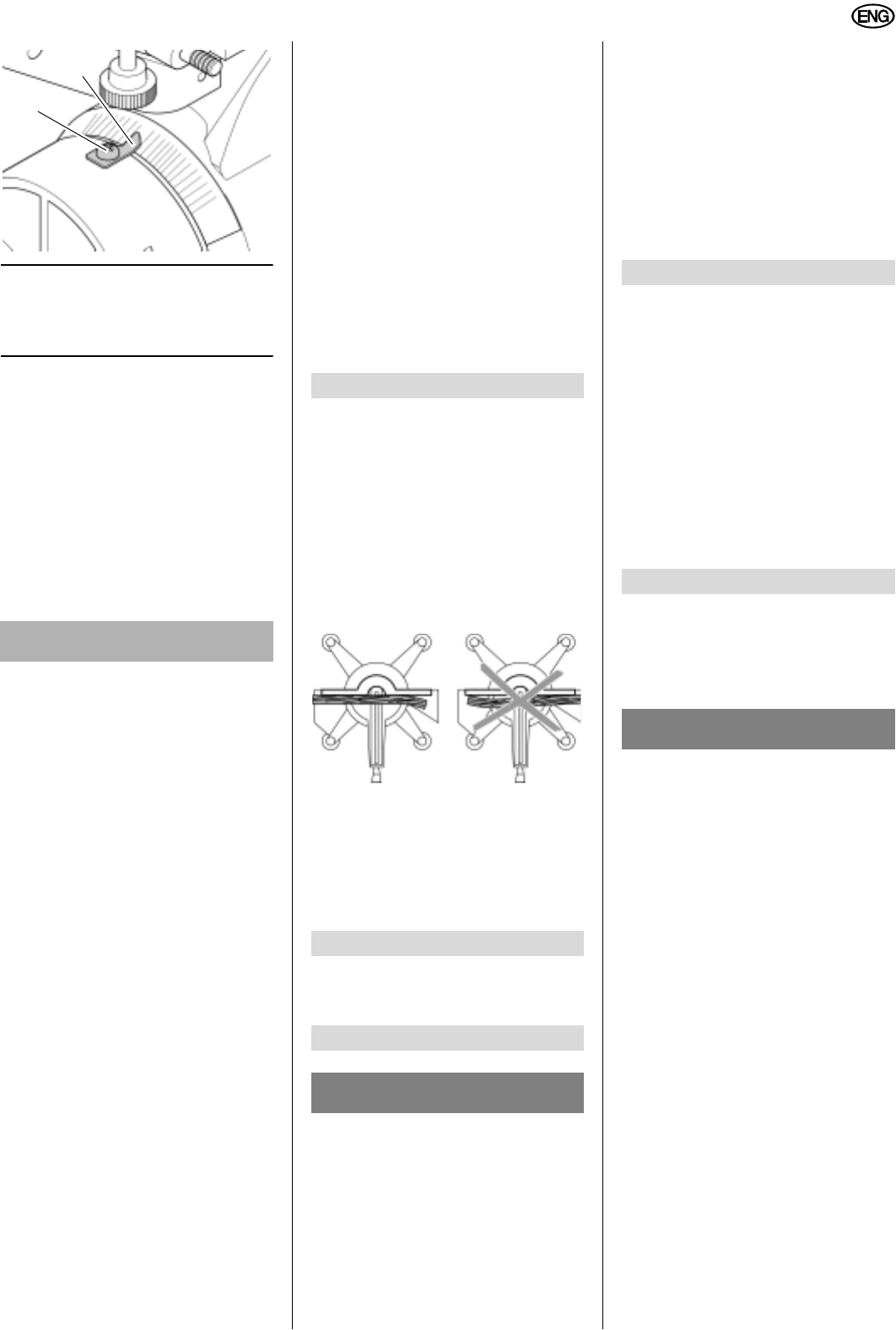

Note:

The track arm holder engages at

preset stops at the 0°, 22.5°, and 45°

position.

9.5 Cleaning

Using a brush and dust pan or vacuum

cleaner, remove all small wood chips

and saw dust from these parts of the

machine:

setting devices;

o perating elements;

the motor ventilation slots;

the space below the kerf plate.

9.6 Storage

9.7 Maintenance

Prior to every use

x Remove all small wood chips and

saw dust from the machine with a

brush and dust pan or a vacuum

cleaner.

x Check the power cord and plug for

damage and if damaged, have the

cord and/or plug replaced by a

qual-

ified electrician.

x Check all moving parts and make

sure that they can move freely and

smoothly across their entire ranges.

Periodically, depending on operating

conditions

x Check the drive belt for wear, tear,

cracking or other damage, as well

as for p

roper tension and tension

(1/8" maximum play in the middle

between the pulleys).

x Check all nuts, bolts and screws for

proper fit and tightness and tighten

where necessary.

x Check if the sawhead assembly

returns to its starting or home posi-

tion after being released. If neces-

sary, have the springs replaced by

fully qualified and factory author-

ized personnel.

For long work pieces use suitable

supports on both sides of the

machine so that

the work pieces do

not bend.

Use an auxiliary fence when cutting

small work pieces.

When cutting warped or bent work

pieces, make sure that you place

the work piece so that the convex

side (i.e. the outer side of the bow)

is against the fence.

Do not cut any work piece while it is

standing on edge; always place it

flat on the rotating table.

Keep all surfaces clean. In particu-

lar, remove resin residue with a

clean cloth.

For

additional assessories please con-

tact metabo.

Defective machines may be sent, after

obtaining a RMA (Return Machine

Authorization) number, shipping charges

pre-paid to the nearest service center.

For more information, including

addresses and phone numbers, please

refer to the Warranty Terms and Condi-

tions at the beginning of this manual.

Please attach a description of the fault to

the machine.

When you call, please have your model

number and date of manufacture handy

(both can be found on the name plate of

the machine), as well as your proof of

purchase (original receipt) and be pre-

pared to explain the problem.

The manufacture recommends that you

save the shipping carton and all packag

-

ing materials at least for the duration of

the warranty period, so that these mate-

rials can be used to return the machine

safely for any warranty claim or repair

that might become necessary.

All packaging materials are recyclable.

Packaging materials should only be dis-

posed of in full compliance with all local,

state and federal regulations for such

materials and respective requirements

for recycling.

This section describes problems and

malfunctions which you should be able

to resolve yourself. If the measures

described here do not solve your prob-

lem, please refer to "Repairs."

Motor does not run

No power

x Check the power cord, plug, outlet

and and fuse or circuit breaker.

No crosscut function

Transport locking pin engag

ed:

x Pull transport locking pin out.

A WARNING

x Store the machine in a dry and

safe place where it cannot be

used or tampered with by unau-

thorized persons or by children.

x Safeguard the machine with a

padlock.

x Never store the machine out-

doors, in unprotected areas or in

damp or wet locations. Please

refer to chapter 15, "Technical

Specifications," for permissible

ambient conditions.

x Store the saw blade(s) in a safe

place and in such a manner that

nobody can get hurt, e.g. put the

saw blade(s) in protective card-

board sleeves.

77

78

10. Tips and Tricks

11. Available Accessories

12. Repairs

A DANGER

Any damaged parts or protection

devices must be replaced by fully

qualified and factory authorized per-

sonnel only.

13. Environmental Protection

14. Trouble Shooting

A DANGER

Troubleshooting is dangerous and

can cause accidents. Therefore

please note the following:

x Make sure the power cord is

unplugged before servicing or

troubleshooting.

x Every time you troubleshoot or

repair the machine, make sure

that all safety devices and pro-

tective guards are undamaged

and fully operational.

x Never operate the machine with-

out all its safety devices being

installed and fully operational.

x If troubleshooting does not

solve your problem, call Cus-

tomer Service. For more details,

please refere to the "Warranty

Terms and Conditions" at the

beginning of this manual.