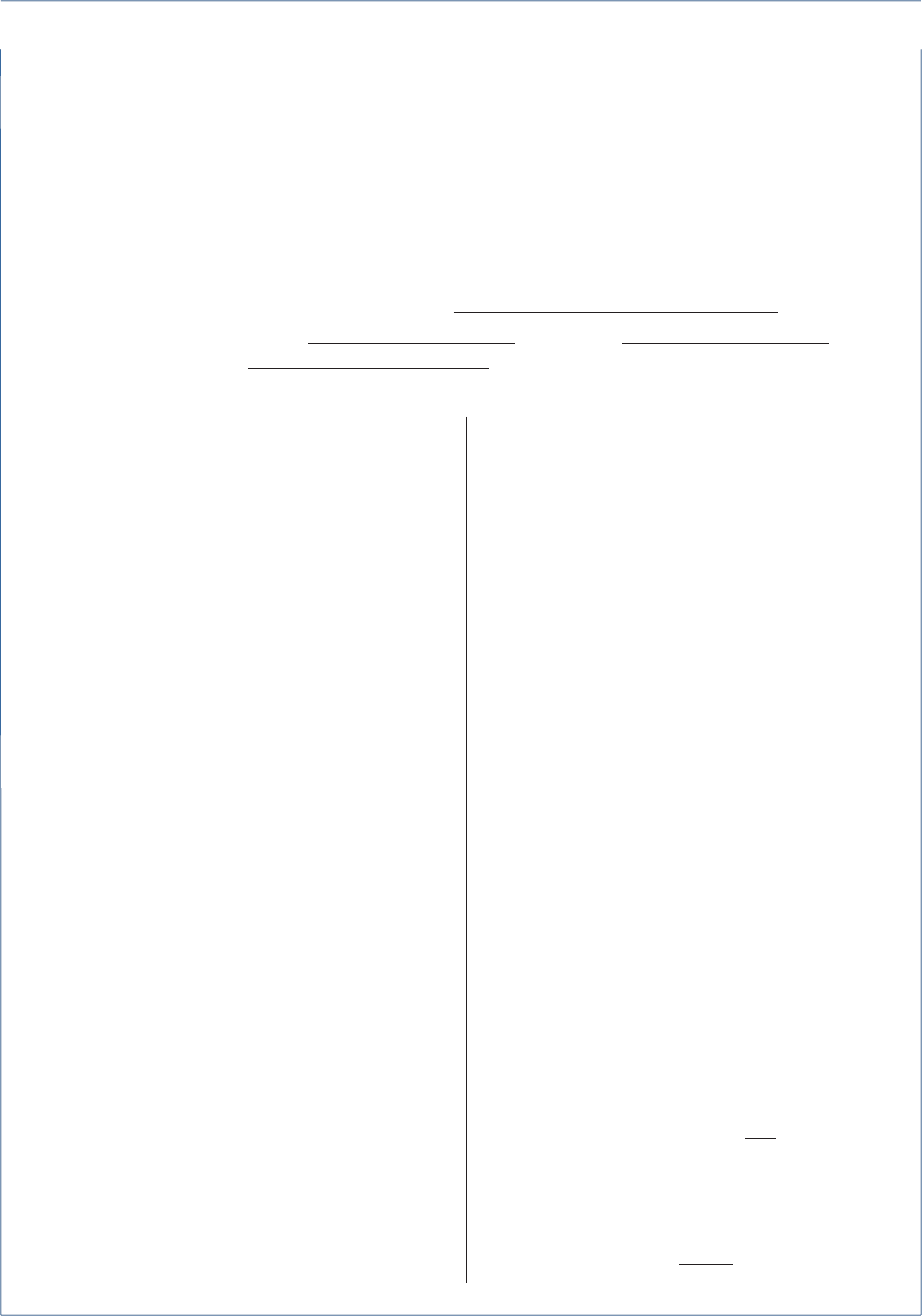

32 - 1

ETC00781(4) Series 100 e 02/2004

17. Analog Output absent RR

18. Fluctuating display without error RR

19. Response time to long RR

20. Chopper has loud noise R

21. Measuring values to high RR

22. Measuring values to low RR

23. Misalignment Display/Analog output RR

24. Limiting values function incorrect RR

25. Adjustment not possible RR

26. Analyzer drift RR

27. Transverse sensitivity to high RR

28. Contamination of analyzer RR

29. Condensation RR

30. Overhaul complete analyzer with R

cost estimate

31. Removal of failures with cost estimate R

32. Removal of failures without cost estimate R

1. No Display (defective) R

2. BATT. is flushing R

3. E 11 is flushing R

4. E 12 is flushing R

5. E 14 is flushing R

6. E 16 is flushing R

7. E 17 is flushing R

8. E 18 is flushing R

9. E 19 is flushing R

10. E 20 is flushing R

11. E 21 is flushing R

12. E 22 is flushing R

13. E 27 is flushing R

14. E 37 is flushing R

15. E 38 is flushing R

16. E 39 is flushing R

Ch1 CH2

CH1 CH2

CH1 CH2

32. Failure Check List

If you experience failures with your analyzer pls. take this checklist to mark the failure(s) before contacting our

service department or sending back the unit (together with a copy of this list). The enclosed information may speed

up trouble shooting and result in cost reduction.

Some failures may need to mark more than one of the following items!

Serial. - No. (to be found on the name plate label):

Measuring range / gas channel 1: channel 2:

Software - Version - No.:

CH1 CH2

CH1 CH2

CH1 CH2

CH1 CH2

CH1 CH2

CH1 CH2

CH1 CH2

CH1 CH2

CH1 CH2

FAILURE CHECK LIST