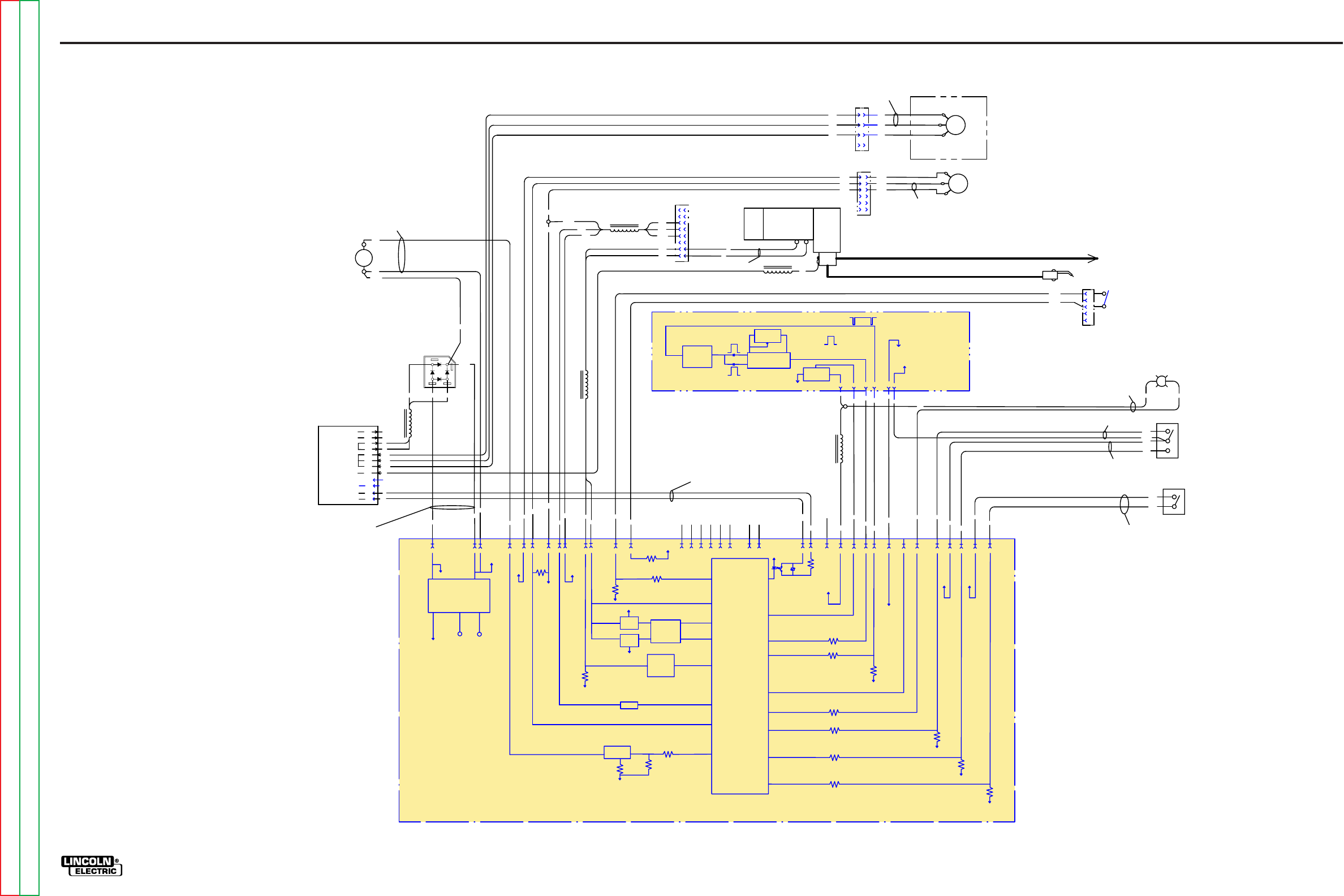

ELECTRICAL DIAGRAMS

G-7

LF-72/74

SCHEMATIC - ENTIRE MACHINE - CODE 11209, 11210, 11211,11227 (G4617-1) LF-72

A

D

C

B

E

554

556

TRIGGER

C

ONNECTOR

J4

559

515

558

COLD FEED

S1

FEED

PLATE

T

RIGGER

I

NPUT

67

556

J1-4

J1-5

J1-11

J1-12

J1-15

559

1

4

3

2

6

5

P

5

8

7

M

OTOR /

G

EARBOX

W

B

L5

515

558

589

587

554

551

550

551

550

576

577

575C

553

552

2

4

KEY

580

552A

605

606

601

607

608

5

15A

THERMAL LED

W

563

563

562

575B

562

B

W

B

1

0K/2W

2

1

P7

4

3

REMOTE

C

ONTROL

VOLTAGE

POTENTIOMETER

(OPTIONAL)

75A

76A

7

7A

WIRE FEED

S

PEED

C

ONTROL

POTENTIOMETER

10K/2W

1

4

3

2

6

5

575

5

77

5

76

5

89

TRIGGER

INTERLOCK

S2

587

-

+

580

4

2

5

52A

41

5

52B

T

IMER KIT

(

OPTIONAL)

SCHEMATIC =

M20336

J60-6

601

5

15A

6

05

607

608

606A

5

52

553

G

AS

S

OLENOID

O

UTPUT

CONTROL

J6

2

C

4

D

77AE

76A

F

75AG

4

1

I

J

42

K

L

M

6

7

N

R

EMOTE

V

OLTAGE

CONTROL

S

ENSE

5

52B

ARC VOLTAGE

ARC CURRENT

2-STEP

GAS PURGE

L

1

5

77A

576A

575A

75

76

7

7

L

2

L3

575

5

75C

5

75B

24-42VAC

L4

5

62

563

15 VDC in

2 STEP

p

osition

5

VDC

when lit

38VDC at

42VAC input

w

ith control

board

disconnected.

60VDC with

control board

connected

1.6V @ 50 IPM

30.6V @ 800 IPM

Motor is located

behind

glastic panel

Lights when motor

current exceeds 4

Amps foran

extended time.

O

ff = 0 VDC

O

CV = 59 VDC

On = 7.7 VDC

Locatedon

CaseFront

Locatedon

C

ase Front

Locatedon

CaseFront

Locatedon

c

ase back

Values for CV300. Others

m

ay be different.

0 VDC @ 0 = 5.8 Arc Volts

6.6 VDC @ 10 = 40 ArcVolts

0 VDC MIN. WFS

5 VDC MAX. WFS

Trigger Interlock does not

stop welding when the

arc is broken. Pull and

release to end the weld.

15 VDC Open

0 VDC Closed

1

5 VDC Open

0 VDC Closed

Gearbox ratio is 2:47

Motor is atelectrode

p

otential

Locatedon

i

nternalpanel

Start-Up

On power-up, the LF-72 will light the

motor thermal LED for 0.5 seconds.

I

f the feeder is powered-up with the

trigger depressed, welding will not start

until the trigger is released and then

depressed again.

To Power Source Electrode Connection

750 ohm

+15V

750 ohm

TRIGGER

OPEN = 0V

CLOSED = 8V

MOTOR

CURRENT

SENSE

SCALING

MOTOR

VOLTAGE

SENSE

BRAKE

FET

DRIVE

FET

0.1 ohm

MOTOR

DRIVE

CIRCUIT

+ POWER

J1-1

+5V

FILTER

TACH

FEEDBACK

(NOT ACTIVE)

0-5V PULSE SIGNAL

FREQUENCY = SPEED

J1-9

J1-13J1-3

100K

ohm

WIRE

FEED

SPEED

0V = MIN SPEED

5V = MAX SPEED

+5V

J

1-8

200 ohm

GAS

SOLENOID

SOLENOID

FET

10K

ohm

0.25

ohm

J

1-2

J

1-6

J1-16

+POWER

COM

COM

BOARD

POWER

SUPPLY

J

14-1

J14-9

MOV

20

ohm

MACHINE

OUTPUT

ENABLE

20 OHM = OUTPUT ENABLED

HIGH IMPEDANCE = OUTPUT DISABLED

J

14-8

J14-14

J

14-2

J14-5

+5V

BURNBACK

0V = 0.02 SECONDS

5V = 0.25 SECONDS

J14-4

EXTERNAL

GAS

SOLENOID

CONTROL

LOW = CONTROL AT CONTROL BOARD

HIGH = CONTROL AT TIMER BOARD

J

14-12

J

14-13

PROGRAM

DO NOT USE

NOT FIELD PROGRAMMABLE

J14-7

200 ohm

THERMAL

LED

5V = OFF

4V OR LESS = ON

J14-10

COLD

FEED

LOW = DISABLE

HIGH = ENABLE

J14-16 J14-11

J

14-15

J

14-3

GAS

PURGE

LOW = DISABLE

HIGH = ENABLE

+15V +15V

TRIGGER

INTERLOCK

LOW = DISABLE

HIGH = ENABLE

+15V

MICRO

CONTROLLER

COMMON ANALOG P.C. BOARD

SCHEMATIC =G4559

Control Board Summar

y

• Has on-board power supply.

• Receives switch signals from Trigger, Cold Feed, Gas Purge, Trigger

Interlock

• Reads WFS potentiometer.

• Communicates with optional timer kit to control burnback, postflow.

• Controls motor speed with PWM.

• Turns Gas Solenoid on, off.

• Monitors motor current, lights yellow thermal LED if over 3.75 amps for an

extended time period. LED remains lit for 30 – 60 seconds to allow motor

to cool.

•

Does NOT support Run-in at this time.

• Operates on 24-42 VAC. Maximum WFS and/or maximum pull force may

be less when operating at 24 VAC.

• Does NOT operate on 115 VAC.

J60-5 J60-8

J

60-7J60-1

J60-3

+15V

COM

COM

BURNBACK

POT

PREFLOW &

POSTFLOWTIMER

LOGIC

POSTFLOW

POT.

A

b

PREFLOW

TIME FIXED

AT 30msec

c

D

POSTFLOW

TIME RANGE

.25 - 10 SEC

FIXED

PULSE

WIDTH

G

ENERATOR

A

c

5V SIGNAL

GAS FLOW

ENABLE

Locatedon

CaseFront

I

NPUT

OUTPUT

b

15V SIGNAL

100 msec PULSES

TOGGLE GAS FLOW ON/OFF

D

Time

r

Board Summar

y

• Has potentiometers for burnback and postflow.

• Preflow fixed at 30msec.

• Burnback range is 0 to 0.25sec.

• Postflow range is 0.25 to 10sec.

•

Receives “Gas FlowEnable” signal.

• Outputs 100 msec pulses to turn Gas Flow On, Gas

Flow Off.

J2-1 J2-2 J2-3 J2-4 J2-5 J2-6 J3-1 J3-2

NOT USEDNOT USED

C

onnectorlocated

by sheetpanel

Motor resistance

is 1.5 ohms

Connector located

behindcase front

P8

Connector located

b

ehindcase front

C

oil

measures

21 ohms

INDEX

MOLEX

+5V

+15V

G-7

NOTE: This diagram is for reference only

. It may not be accurate for all machines covered by this manual.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC