LF-72/74

INSTALLATION

AA-18 AA-18

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

ALUMINUM WIRE PREPARATIONS

ELECTRIC SHOCK can kill.

• Turn the input power OFF at the dis-

connect switch before working on

this equipment.

• Do not touch electrically hot parts.

------------------------------------------------------------------------

Welding with aluminum filler wires requires extra care.

Aluminum wire is softer and not as stiff as steel wires,

it is important to keep aluminum wire free of dirt and

scratches. Limit gun length to 10 Ft.(3.0 m) for best

results and use a spool cover if feeding from a spool.

To prevent scratching of the aluminum wire, remove

the ball bearings from the ball housing as follows.

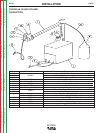

Tools required: (See Figure AA.12b)

• 9/64" Hex key wrench

1. Turn off power at the welding power source.

2. Remove the o-ring holding the ball bushing assem-

bly to the back of the wire feeder. Remove the ball

bushing assembly.

FIGURE AA.12b

3. Remove the three socket head cap screws from the

ball bushing assembly.

Caution: as the screws are

being loosened, the balls may fall free from the

assembly. Remove the balls and the steel washer.

FIGURE AA.13

4. Place the ball bushing housing into the wire feeder

case and secure with the “O” ring.

WARNING

"O" RING