LF-72/74

OPERATION

BB-3 BB-3

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

General Functional Description

The LF-74 fulfills the need for an economical wire feed-

er with a high performance wire drive. Functional fea-

tures included are those that offer the most value – a

WFS knob with a calibrated printed scale, cold-feed/

gas purge switch, trigger interlock switch and tachome-

ter motor control.

RECOMMENDED PROCESSES

•

GMAW

• FCAW

PROCESS LIMITATIONS

• The LF-74 is not recommended for GMAW-Pulse

Synergic, GTAW, GTAW-Pulse, CAG, SMAW

• The LF-74 is not compatible with push-pull equip-

ment.

• For the heavy duty bench models K2426-2 and

K2426-3, the maximum spool size = 60 lb. (27.2 kg).

REQUIRED EQUIPMENT

Lincoln’s LF-74 is designed for use with the CV and DC

family of power sources. These include:

• CV-250 • DC-400

• CV-300 • DC-600

• CV-305 • DC-655

• CV-400 • Invertec V350

• CV-655

OTHER COMPATIBLE POWER SOURCES

• Ranger 250

• Ranger 305

• Commander 300

• Vantage 300

• Vantage 500

• Air Vantage 500

EQUIPMENT LIMITATIONS

• Maximum GMAW gun length = 25’ (7.6m)

• Maximum FCAW gun length = 15’ (4.6m)

• Maximum conduit length = 30' (9.1m)

• Maximum total control cable length = 100ft (31m)

• The LF-74 operates on 24-42VAC and not 115 VAC

• The K1733-1 and K1733-3 wire straighteners are not

compatible with the LF-74

• Gun bushings are required for welding guns that do

not have a Magnum (Tweco #2-#4 compatible) back

end.

• The LF-74 does not attach to K303 or K377 wire reel

stands.

PRODUCT DESCRIPTION

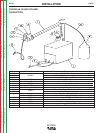

General Physical Description

The LF-74 is optimized for GMAW and FCAW welding.

The powerful 4 roll MaxTrac™ drive, heavy duty enclo-

sure and wire reel stand combine to make an easy to

install, easy to use wire feeder for everyday welding.

Powering the wire drive is a high performance motor

gearbox. A heavy duty hinged door opens easily, which

provides an ample amount of room for assembling pre-

cision drive components and the welding gun.

MaxTrac™ technology delivers great feeding because:

• Patent pending drive rolls improve traction.

• The precision machined, rigid aluminum alloy frame

results in maximum drive roll clamping pressure.

• Drive hubs with steel inner cores have 3 ball bear-

ings inside each hub.

• The drive hubs are supported by large, heat treated

and ground shafts for maximum rigidity and accurate

drive roll alignment.

• Patent pending dual spring pressure arms have sen-

sitivity for feeding soft wires without crushing them,

and have plenty of compression force for feeding

solid or stiff wires.

Easy to configure, easy to service parts give

MaxTrac™ drives the edge in productivity.

• Patented split wire guides fully support the wire and

virtually eliminate birdnesting.

• No tools required to change the drive rolls and wire

guides.

• Changeable gun bushings easily accept guns from

many manufacturers.

• Brass-to-brass connections between the electrode

connection and the gun minimize voltage drop varia-

tions, resulting in consistent arc performance all day,

every day.

Three models of the LF-74 are available to satisfy

many customer set-ups:

• The base model is enhanced for GMAW welding with

consumables from bulk packages or when a boom

mounting is required.

• The bench model with heavy duty wire reel stand tar-

gets operators performing GMAW or FCAW welding

using consumables on spools.

• The high torque model features high ratio gearing for

feeding larger diameter FCAW or GMAW wires.

All models use a high performance motor-gear box

with an integrated tachometer.