Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

G-10G-10

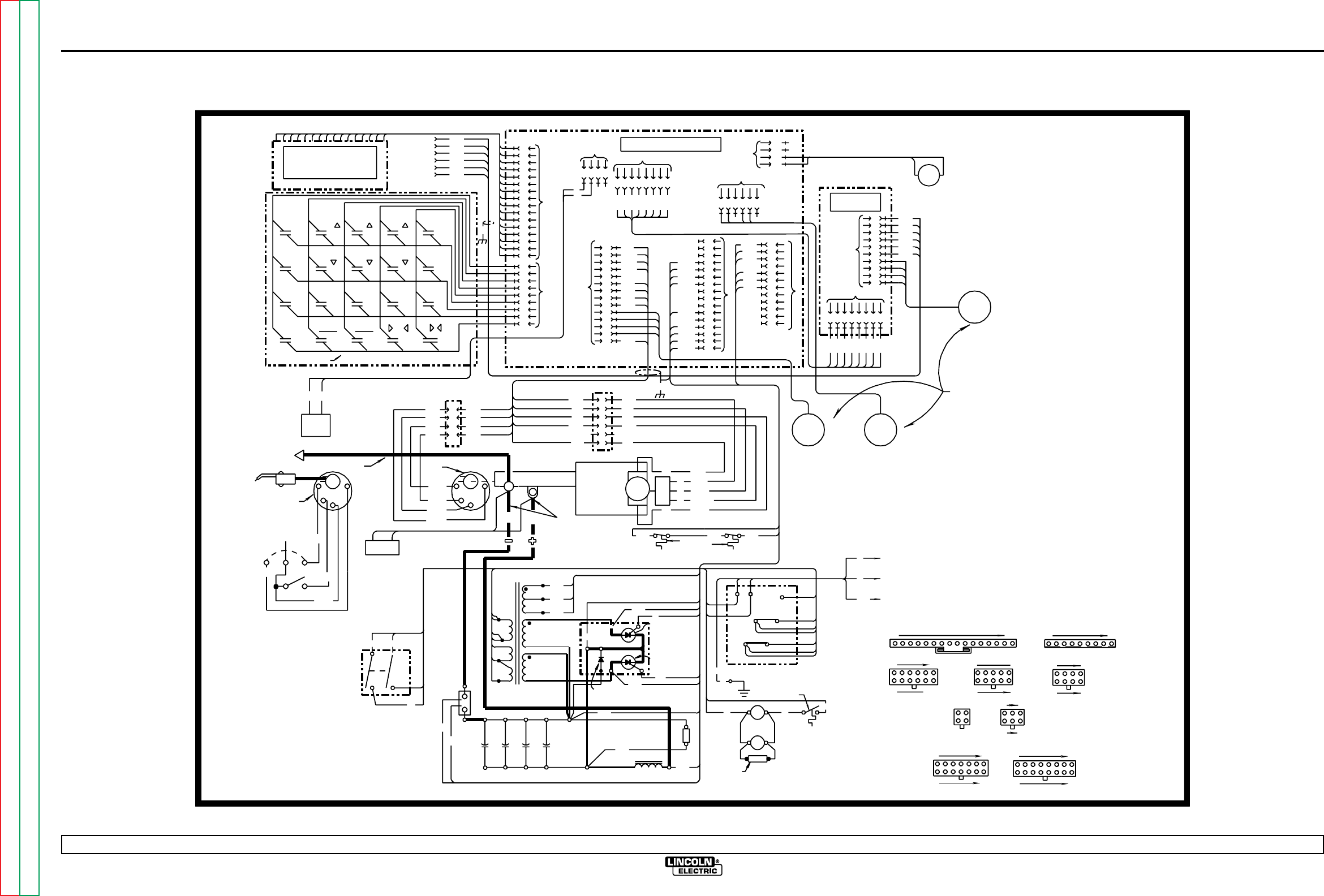

IDEALARC SP-250 IDEALARC SP-250

ELECTRICAL DIAGRAMS

WIRING DIAGRAM FOR CODE 9546 & 10002

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The specific diagram for a particular code is pasted inside the machine on one of the enclosure panels.

GENERAL INFORMATION

COLOR CODE:

B - BLACK

W - WHITE

THERMOSTAT

202

204A

203

204

208

G1

X2

X1

G2

209

SCR 1

250V

470A

SCR HEATSINK

ASBLY

SCR 2

250V

470A

C1 C2

C3

C4

++++

POWER TRANSFORMER

H1

T1

L1 L2

H1

LINE

SWITCH

S1

L1

GND.

RECONNECT PANEL

L1

L2

GND

TO SINGLE PHASE

SUPPLY LINE

TO GROUND PER

CODE

P2

T1

FAN

MOTORS

T2

P1 P2

S2

THERMOSTAT

N.E.

207

206

OUTPUT

CHOKE

NOTES

N.A. WELDING CABLE MUST BE OF PROPER CAPACITY FOR THE

CURRENT AND DUTY CYCLE OF IMMEDIATE AND

FUTURE APPLICATIONS.

N.B. THIS DIAGRAM SHOWS THE "ELECTRODE" POLARITY

N.C. CONNECTOR SHOWN GEARBOX SIDE VIEW.

D1

300V

85A

*

INDICATES CONNECTOR CAVITY NO.

ELECTRICAL SYMBOLS PER E1537

OFF AND REVERSE LEAD CONNECTIONS AT CABLE

CONDUCTOR STRAP AND WORK STUD.

NATIONAL ELECTRICAL

L2

C1 THRU C4

30,000 MFD

50V

H1

H4

320

THERMOSTAT

S3

N.E.

S4

R2

"POSITIVE". TO CHANGE POLARITY, TURN THE UNIT

N.E. THERMOSTATS MOUNTED ON CHOKE COIL

S2 MOUNTED CLOSEST TO FAN; S3 MOUNTED CLOSEST TO

POWER TRANSFORMER.

N.F. KEYPAD MATRIX SHOWN FRONT VIEW.

R - RED

U - BLUE

2.5K

10W

G

X3

X4

X5

X6

X7

N.H. RESISTOR R2 MOUNTED ON FAN SENSOR BRACKET.

N.J. CONNECTOR SHOWN PIN SIDE VIEW.

N.H.

N.G.

15 OHMS

100 W

R1

PROCESS

WIRE/

GAS

AUTO

MEMORY

1

TIMERS

OFF

234

5

SAVE

SPOT

SET SET

DISPLAY DISPLAY

TOGGLE

45

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

LCD DISPLAY

2 LINE X 16 CHAR.

5

3

1

7

9

6

8

2

4

12345678

SP - 250

12345678

555

GAS

SOLENOID

KEYPAD MATRIX

MANUAL

*

*

*

*

(J1)

(J2)

(J4)

CONTROL BOARD

1234

*

1

2

3

4

*

(J7)

(J8)

B

R

A

B

C

D

E

F

(J13)

OPTIONAL SPOOL OR PULL

GUN RECEPTACLE

ALPHA-NUMERIC

IPM

VOLTS

515

541A

495

542

543

(J11)

(J12)

1

2

3

*

123456

*

(J9)

209

208

204A

204

207

206

GND

G1

G2

320

1

2

3

4

5

6

7

8

9

10

11

12

(J3)

*

515

541A

495

542

543

541B

321

539B

322

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

*

1

2

3

4

5

6

7

8

9

10

11

12

13

14

*

(J5)

(J6)

326

327

324

206S

205

541B

539B

322

321

325B

324B

325A

324A

206A

206B

515B

325

539

541

325A

SPOOL GUN

MODULE

6

7

8

4

5

9

10

324B

325B

325A

324A

206A

GND

541

555

539

W

B

T

A

C

H

P.M.

MOTOR/

GEARBOX

324

325

TO

WORK

N.A.

324

325

TRIGGER

INC.

DEC.

207

206

N.B.

N.C.

B

R

PIEZO

ALARM

B

R

U

326

327

326

327

THUMB

SWITCH

R.F. FILTER

326

326

325

325

1

3

2

4

1

3

2

4

5

6

539

541

555

539

555

541

327

327

324

324

515B

206B

515B

206B

515B

206B

GND

STITCH

N.F.

N.J.

202

203

325A

(COMPONENT SIDE OF P.C. BOARD)

14

58

1

J4

J7

J2

19

1

16

12

34

13

46

CAVITY NUMBERING SEQUENCE

J3

J1

1

6

10

5

J9

J11

J12

J8

J5

J6

6

712

1

7

1

8

9

16

8

14

TOP

205

206S

+

-

SHUNT

R.F. CHOKE AS'BLY.

H4

H3

H5

H2

P2

5

13

42

H4

H5

H2

H2

H3

H1

328

(SHOWN CONNECTED

FOR 230 VOLT.)

N.G. THERMOSTAT S4 MOUNTED ON FAN SENSOR BRACKET.

204

2-28-92B

L7977

SP-250 (230/460/575V) - WIRING DIAGRAM