F-23

TROUBLESHOOTING & REPAIR

F-23

IDEALARC SP-250

TEST PROCEDURE

1. Disconnect main AC input power to

the machine.

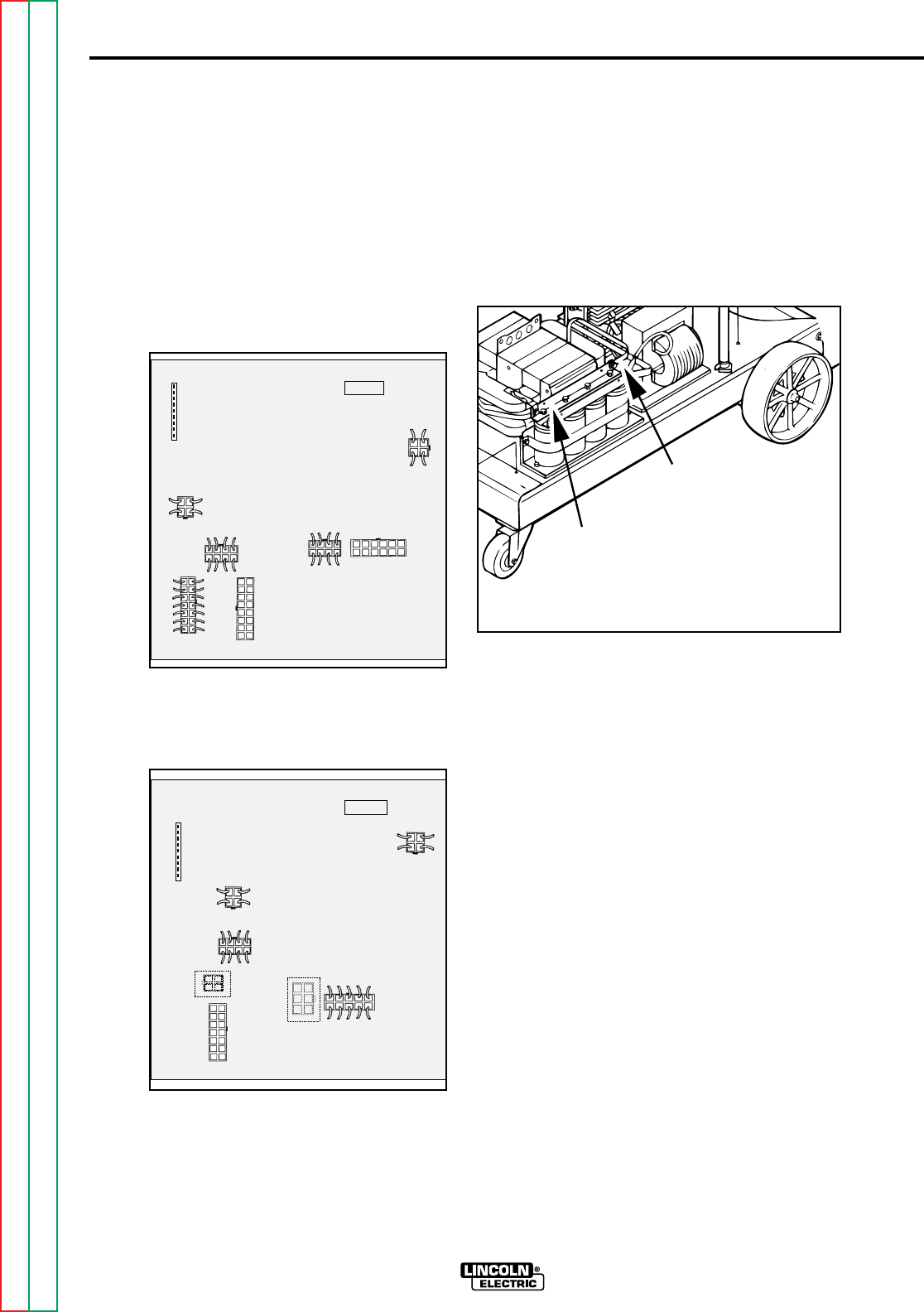

2. Disconnect Molex Plugs J3 and J6

from the G2252 Control Board or

remove Plug J3 from G1992 Control

Board (Code 9402 only)

See Figures F.5A and F.5B.

FIGURE F.5A - Control Board Molex

Plug Locations for G2252 PC Control

Board.

FIGURE F.5B - Control Board Molex

Plug Locations for G1992 PC Control

Board (Code 9402 only.)

3. Test with an Analog Volt-Ohm meter

that capacitors have completely dis-

charged.

4. Disconnect leads X2 and X3 from

the negative capacitor bank using a

fi" open end wrench.

See Figure F. 6.

FIGURE F.6 - Location of Leads X2

and X3.

5. Separate leads X2 and X3 from the

negative capacitor bank buss bar.

Be sure there is no electrical con-

tact. See Figure F6.

NOTE: DO NOT DISASSEMBLE THE

SCR RECTIFIER HEAT SINK ASSEM-

BLY.

6. Construct the circuit shown in Figure

F.8. One 6-volt lantern battery can

be used. R1 and R2 resistor values

are ±10%. Set voltmeter scale low,

at approximately 0-5 volts or 5-10

volts.

a. Test the voltage level of the bat-

tery. Short leads (A) and (C).

Close switch SW-1. Battery

voltage should be 4.5 volts or

higher. If lower, replace the bat-

tery.

ACTIVE SCR RECTIFIER ASSEMBLY TEST

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

SP-250 CONTROL

G2252

J7

J4

J5

J6

J9

J3

J8

J2

SP-250 CONTROL

J7

J4

J5

J3

J6

J9

J8

G1992

J2

LEADS

X2 AND X3

NEGATIVE

CAPACITOR

BANK

BUSS BAR