B-5

OPERATION

B-5

CONTROLS AND SETTINGS

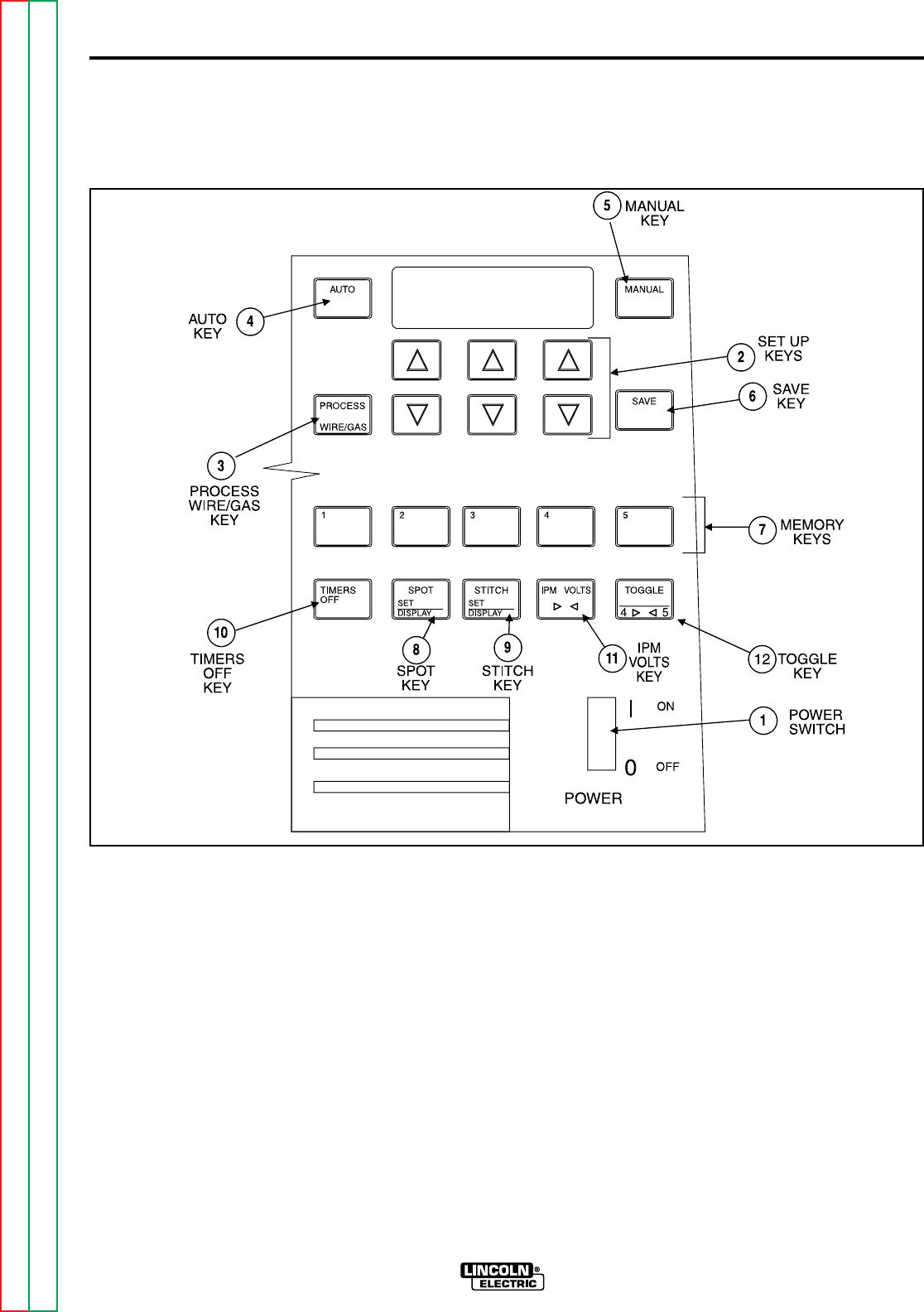

All operator controls are located on the Front Panel

Keypad/Nameplate. See Figure B.1 for the location of

each control.

FIGURE B.1 - SP-250 Control Panel Keys

1. POWER SWITCH: Toggle switch to turn input

power ON and OFF. When the switch is in the ON

position the red LED backlighting of the LCD dis-

play lights and alphanumeric characters appear.

The welding setup in operation when the power

was shut off or disconnected is displayed when

power is restored.

2. SET UP ARROW KEYS: Press keys to

change the display selection directly above the

keys. See Figure B.1. Function of arrow keys

change depending on PROCESS KEY being used.

For function of arrow keys, refer to each process or

procedure. See Table B.1 for summary of arrow

key operation.

3. PROCESS WIRE/GAS KEY: Press key to

display the Wire Type, Wire Diameter, and Welding

Gas. Each combination of wire and gas dictates a

unique relationship between the wire feed speed

and the arc voltage. The SP-250 uses this unique

relationship, along with the metal thickness, to set

the proper values for wire feed speed and arc volt-

age. Therefore, it is very important that the wire

type, wire diameter, and welding gas displayed

match the actual wire type, wire diameter, and

welding gas being used for the weld.

IDEALARC SP-250

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC