Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

F-7

TROUBLESHOOTING & REPAIR

F-7

IDEALARC SP-250

TROUBLESHOOTING GUIDE - Observe all Safety Guidelines detailed throughout this manual

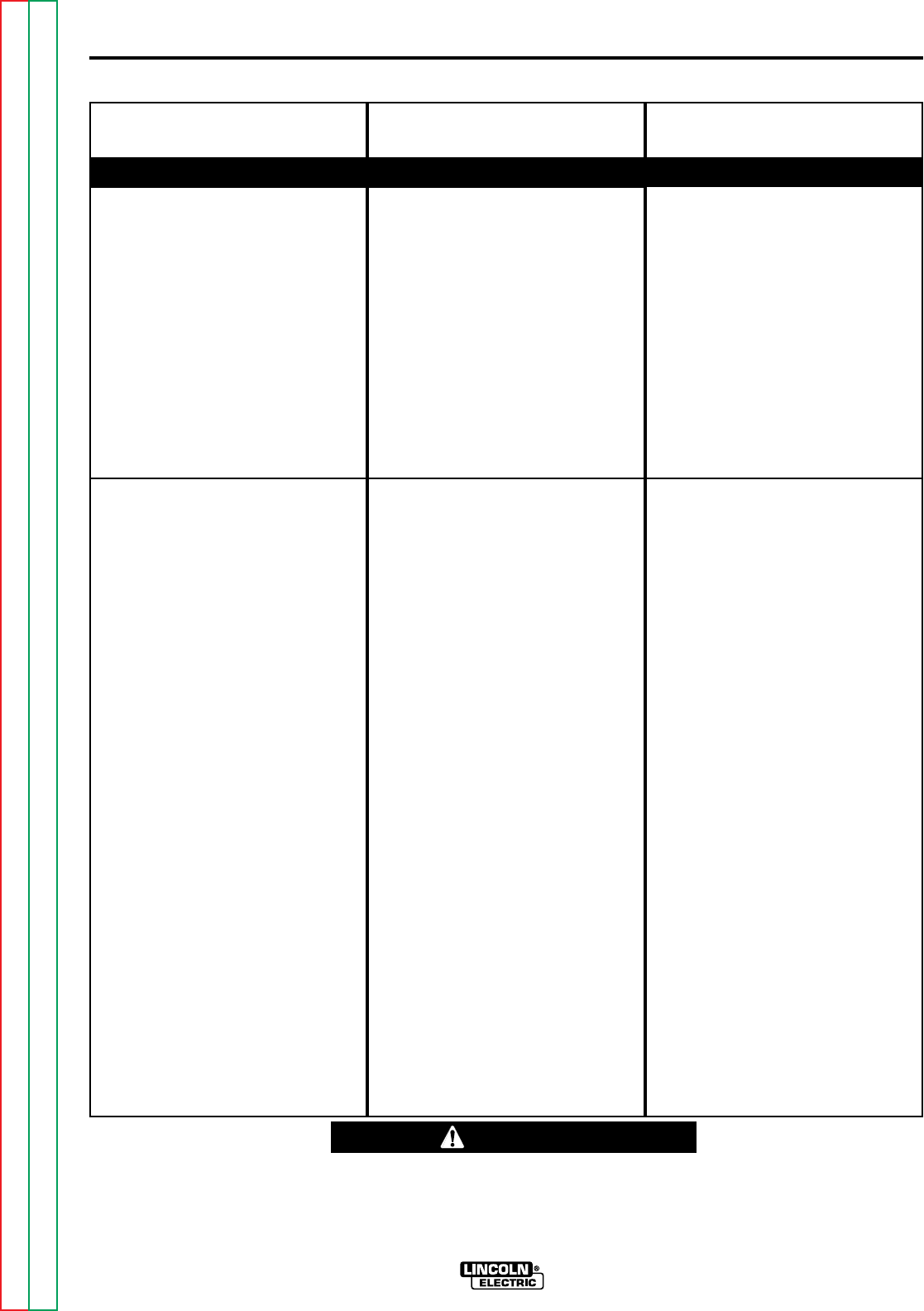

FUNCTION PROBLEMS

PROBLEMS

(SYMPTOMS)

POSSIBLE AREAS OF

MISADJUSTMENTS(S)

RECOMMENDED

COURSE OF ACTION

The display backlight does not func-

tion.

The machine stops feeding wire

while welding and the MOTOR

OVERLOAD message appears on

the display.

1. With the display board discon-

nected test for 12VDC from pins

1J1(+) to 2J1(-). If the 12VDC is

present and the display board

backlight does NOT function

then replace the display board.

See Wiring Diagram.

2. If the 12VDC is not present at

pins 1J1 to 2J1 then perform the

Main Transformer Test.

3. The control board may be faulty.

Replace.

1. Check the motor armature cur-

rent. Normal armature current is

1.5 - 2.5 amps.

If the motor armature current is

normal the control board may be

faulty.-Replace.

2. If the motor armature current is

high (over 3 amps) and there are

NO restrictions in the wire feed-

ing path then the motor or gear

box may be defective.-Replace.

1. Check the input voltage at the

machine. Input voltage must

match the machine rating plate

and the reconnect panel.

1. Check for mechanical restric-

tions in the wire feeding path.

The gun cable may be clogged.

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, con-

tact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed call 216-

383-2531 or 1-800-833-9353

CAUTION