OPERATION

B-3B-3

LN-25™

VOLTMETER

(Factory installed on model Codes above 9218)

The 40V DC analog voltmeter is mounted to the front

control panel of the LN-25™ and is connected to read

the arc voltage between the LN-25™ electrode cable

connection and the work clip lead.

NOTE:

1. The Voltmeter will read zero if the LN-25™ work

clip lead is not connected to work, even if the

elec trode is electrically “hot” to work.

2. The Voltmeter will read below zero if the LN-25™

polarity switch is not set to the same polarity as

the electrode.

3. The Voltmeter will read power source open circuit

voltage when the gun trigger is open, even if the

LN-25™ is equipped with the internal contactor.

“ELECTRODE POLARITY” SWITCH

The polarity switch is located on the front panel of the

LN-25™ case.

Set the switch to the same polarity as the electrode

lead connection to the power source. If the switch is

not set for the correct polarity, the wire feeder will not

operate.

WIRE FEED MODE SWITCH

The CV-VV (CC) Wire Feed Mode switch is located

inside the LN-25™ case. The toggle switch extends

from be neath the control box just above the wire drive.

The forward “CV” position provides constant wire feed

speed mode for use with constant voltage (CV)

welding power sources.

The backward “VV (CC)” position provides arc-sensing

wire feed speed mode for use with constant current

(formerly variable voltage) welding power sources.

WIRE SPEED DIAL AND RANGE SWITCH

The Wire Speed control dial on the front panel of the

LN-25™ has two calibrated dial ranges selected by

the HI-LO Dial Range switch.

When switched to the LO range position, the constant

wire feed speed (CV Wire Feed Mode) is set on the

inside (white) dial range calibrated for 50 to 350 in/min.

When switched to the HI range position, the constant

wire feed speed (CV Wire Feed Mode) is set on the

outside (black) dial range calibrated for 50 to

700 in/min.

The volts marks around the HI range calibrated dial

indicate the minimum arc volts required to obtain the

indicated HI range wire feed speeds. For example; if

wire speed is set to 400 in/min., a welding procedure

arc voltage of at least 17V would be required to obtain

the 400 in/min. wire feed speed.

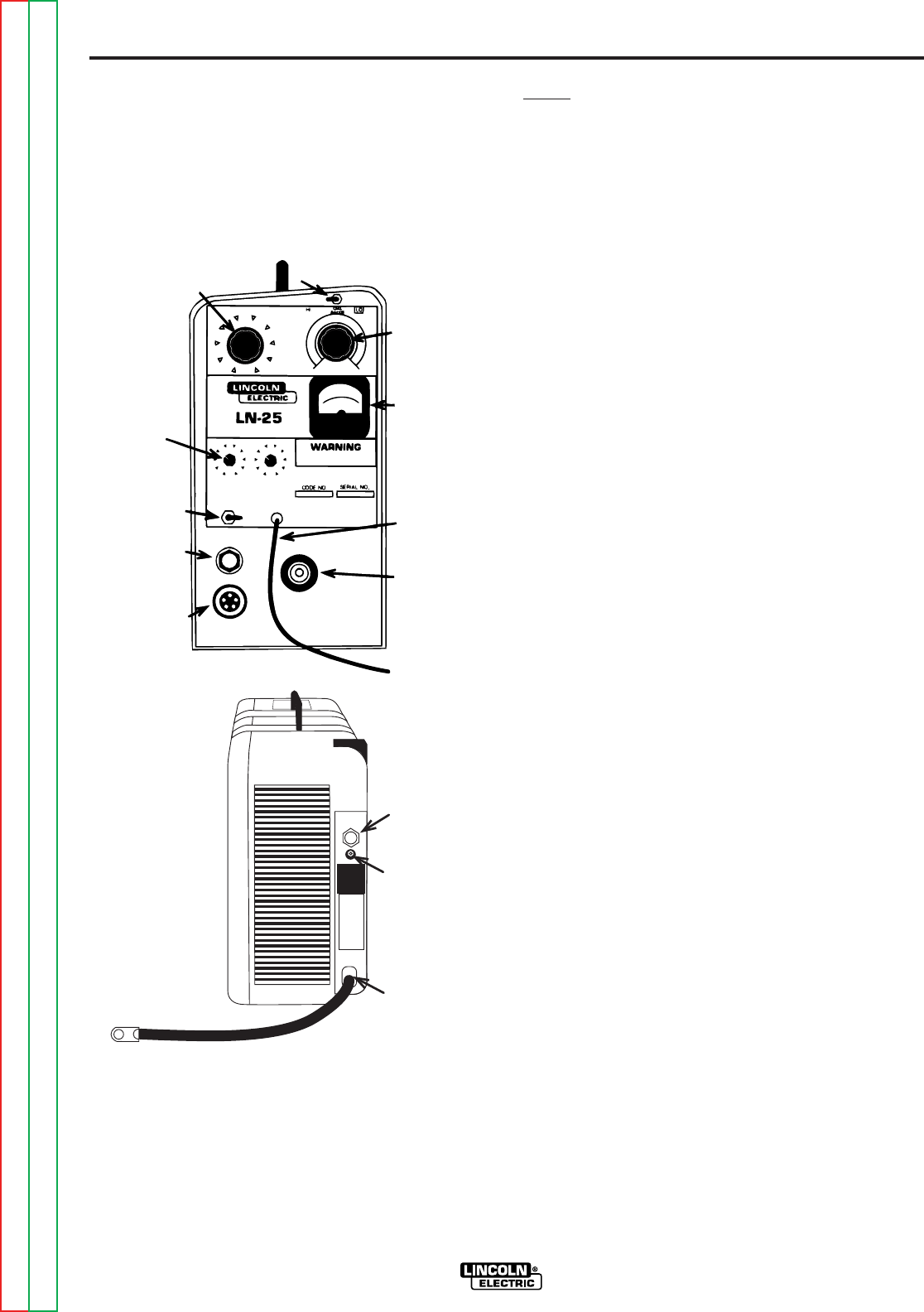

LN-25™ INSTRUMENTS AND

CONTROLS

Refer to Figure B.1 for control locations.

REMOTE

ARC VOLTAGE

CONTROL

(OPTIONAL)

WIRE SPEED

DIAL RANGE

SWITCH

WIRE

SPEED

DIAL

VOLT

METER

WORK CLIP

LEAD

GUN

CONNECTION

BLOCK

GUN

TRIGGER

AMPHENOL

CONNECTOR

GAS

FITTING

(OPTIONAL)

ELECTRODE

POLARITY

SWITCH

GAS POST/

PRE FLOW

TIMERS

(OPTIONAL)

ELECTRODE

CABLE

OPTIONAL

GAS INPUT

FITTING

GAS PURGE

BUTTON

FIGURE B.1 – CONTROL LOCATIONS.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC