TROUBLESHOOTING AND REPAIR

F-40F-40

LN-25™

REPAIR PROCEDURE

1. Open the case door. Remove the wire reel by

removing the retaining collar. See Figure F.5.

2. Remove the screws holding the control box

cover in place and remove the control box

cover. See Figure F.5.

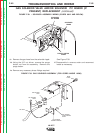

3. Remove the baffle from in front of the contactor.

See Figure F.25.

4. Remove the 5/16" screw holding the contactor

in place.

5. Remove the two 11/16" brass nuts holding

voltage sensing lead #67 and the welding

cables to the contactor.

6. Disconnect the contactor coil leads by

separating the two in-line connectors behind

the reel stand assembly. For codes 9812 and

below, remove the two contactor coil leads from

the contactor PC board. See Figure F.25.

7. Cut or remove any cable ties or harness tape

as necessary.

8. Carefully remove the contactor from the LN-

25™.

9. Install a new contactor in the LN-25™.

10. Connect the contactor coil lead in-line

connectors behind the reel stand assembly.

See Figure F.25. For codes 9812 and below,

install the contactor coil leads onto the

contactor PC board. See Figure F.19.

11. Install the welding cables and voltage sensing

lead #67 to the contactor and secure with the

two 11/16" brass nuts. See Figure F.25.

NOTE:

Be sure brass nuts are tight. 11 ft-lb

torque is recommended.

12. Install the 5/16" screw to secure the contactor

in place.

13. Install the baffle in front of the contactor.

14. Install the control box cover and secure by

installing the three screws. See Figure F.5.

15. Install the wire reel and retaining collar and

close the case door. See Figure F.5.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

CONTACTOR REPLACEMENT

(continued)

FIGURE F.25 - CONTACTOR REPLACEMENT.

VOLTAGE SENSING

LEAD 67

WELDING CABLES

C

ONTACTOR

BAFFLE

5/16" SCREW

REEL STAND

A

SSEMBLY

I

N-LINE

CONNECTORS

11/16" BRASS

NUTS