OPERATION

B-7B-7

LN-25™

screw in the gearbox conductor block and pull the

gun cable forward about six inches. There should

be a slight waviness in the exposed wire. If there

is no waviness, the pressure is too low. Increase

the pressure setting

1

⁄4 turn, lock the gun cable in

place and repeat the above steps.

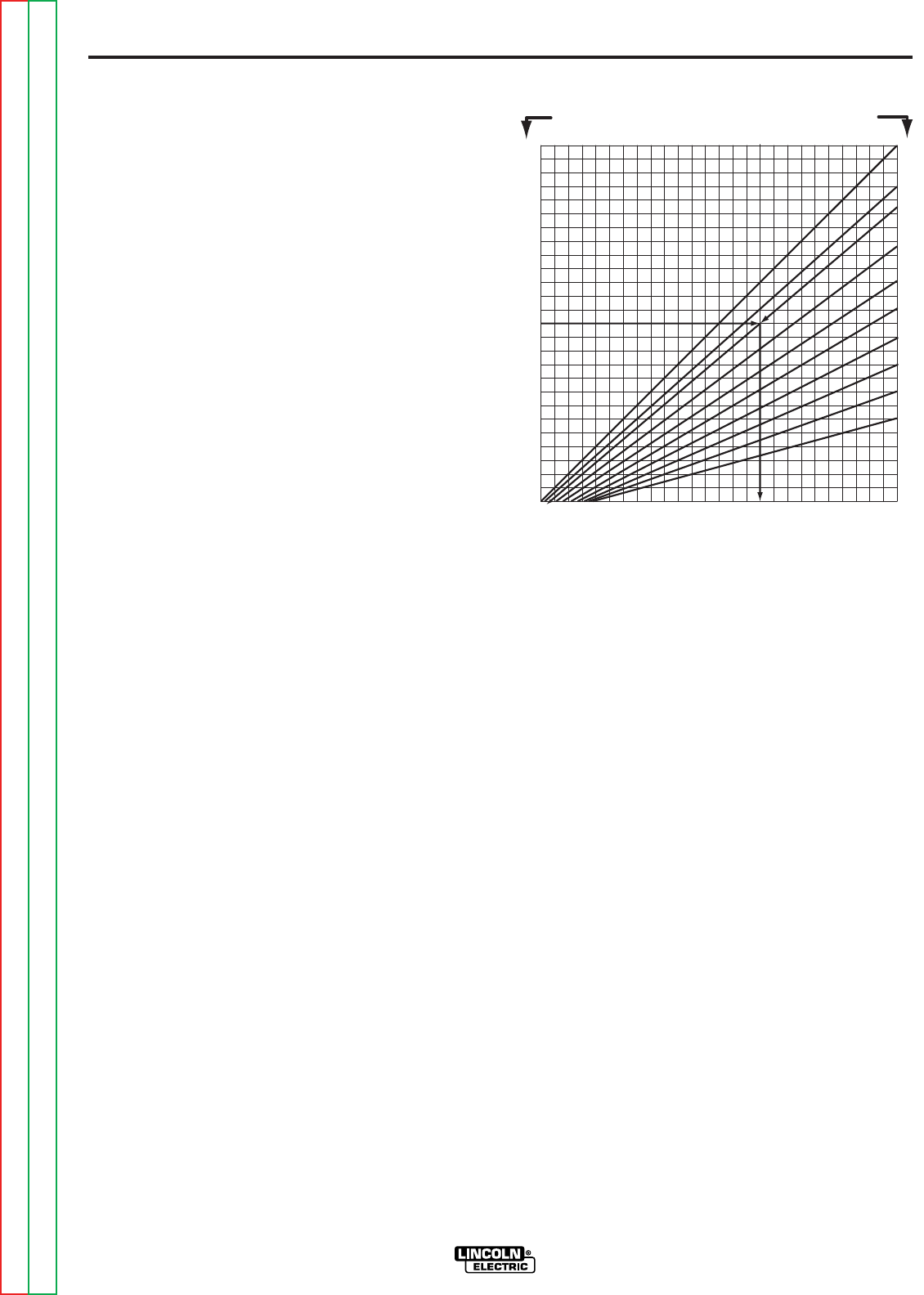

DESIRED IN/MIN ARC VOLTS USED

700

650

600

550

500

450

400

350

300

250

200

150

100

50

50 100 150 200 250 300 350 400 450 500 550 600 650 700

35

31

29

27

25

23

21

19

17

15

PRESETTING WIRE FEED SPEED

The LN-25™ permits accurate presetting of the

desired wire feed speed, before welding, in both CV

and CC wire feed modes.

SETTING CONSTANT WIRE FEED SPEED (CV

MODE)

a. Set Wire Feed Mode switch to CV position.

b. Set Dial Range switch to LO position for wire feed

speeds up to 350 in/min., or HI position for wire

feed speeds over 350 in/min.

c. Set Wire Feed dial to the desired wire feed speed

on the selected calibrated dial range.

The wire speed will remain constant at the value set,

independent of arc voltage changes, as long as the

arc voltage does not drop below the value per the

chart below for the max. wire feed speed shown:

Maximum Speed Minimum Arc Volts

350 IPM 15V

400 IPM 17V

500 IPM 21V

600 IPM 24V

700 IPM 27V

SETTING ARC SENSING WIRE FEED SPEED

(CC MODE)

When using a constant current (formerly variable

voltage) power source, welding performance is im -

proved using arc sensing wire feed speed (CC [VV]

mode). In this wire feed mode the wire speed

increases if arc voltage increases, and decreases if

arc voltage de creases, but remains constant at any

specific voltage level.

The LN-25™ permits accurate CC mode presetting of

the desired wire feed speed, for the desired arc

voltage to be used, by setting the Wire Speed dial in

the fol lowing manner before welding:

a. Set Wire Feed Mode switch to CC position.

b. Referring to the graph located above the Mode

switch (also shown in Figure B.3):

1. Select the horizontal line representing the DE -

SIRED IN/MIN. for the welding procedure. (See

example arrow line for 375 in/min.)

2. Select the diagonal line representing the ARC

VOLTS to be used for the welding procedure.

(See example arrow line for 29 volts.)

3. Determine the vertical line representing the CC

WIRE SPEED SETTING where the above two

lines cross. (See example arrow line for 450.)

c. Set the Wire Speed dial to the value determined

in Step (3) above (450 for example used). Use HI

Dial Range if value to be set is over 350.

The wire will feed at the DESIRED IN/MIN speed

when the welding power source is set to the arc

voltage to be used for the weld procedure (375 in/min.

at 29V for example used).

A chart representation of the CC wire speed setting

graph is shown in Figure B.4, giving the Wire Speed

dial setting required for the DESIRED IN/MIN and

ARC VOLTS used for the welding procedures:

FIGURE B.3 – CC WIRE SPEED SETTING.

CC Wire Speed Setting

(Hl or LO Range)

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC