POWER MIG 255

OPERATION

B-5 B-5

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

PROCEDURE FOR CHANGING

DRIVE AND IDLE ROLL SETS

1. Turn off the power source.

2. Release the pressure on the idle roll by swinging

the adjustable pressure arm down toward the

back of the machine. Lift the cast idle roll assem-

bly and allow it to sit in an upright position.

3. Remove the outside wire guide retaining plate by

loosening the two large knurled screws.

4. Twist the drive roll retaining mechanism to the

unlocked position.

5. Wiggle both the metal idle and drive rolls off of

their plastic hubs.

6. Remove the inside wire guide plate.

7. Replace the drive and idle rolls and inside wire

guide with a set marked for the new wire size.

NOTE: Be sure that the gun liner and contact tip are

also sized to match the selected wire size.

8. Manually feed the wire from the wire reel, over the

drive roll groove and through the wire guide and

then into the brass bushing of the gun and cable

assembly.

9. Replace the outside wire guide retaining plate by

tightening the two large knurled screws.

Reposition the adjustable pressure arm to its orig-

inal position to apply pressure. Adjust pressure as

necessary.

WIRE REEL LOADING -

READI-REELS, SPOOLS, OR COILS

To Mount a 30 lb (14 kg) Readi-Reel

Package (Using the Molded Plastic K363-P

Readi-Reel Adapter:)

1. Open the wire drive compartment door.

2. Depress the release bar on the retaining collar

and remove it from the spindle. See Figure B.2.

3. Place the optional adapter on the spindle.

4. Re-install the retaining collar. Make sure that the

release bar “pops up” and that the collar retainers

fully engage the retaining ring groove on the

spindle.

5. Rotate the spindle and adapter so the retaining

spring is at the 12 o'clock position.

6. Position the Readi-Reel so that it will rotate in a

direction when feeding so as to be de-reeled from

top of the coil.

7. Set one of the Readi-Reel inside cage wires on

the slot in the retaining spring tab.

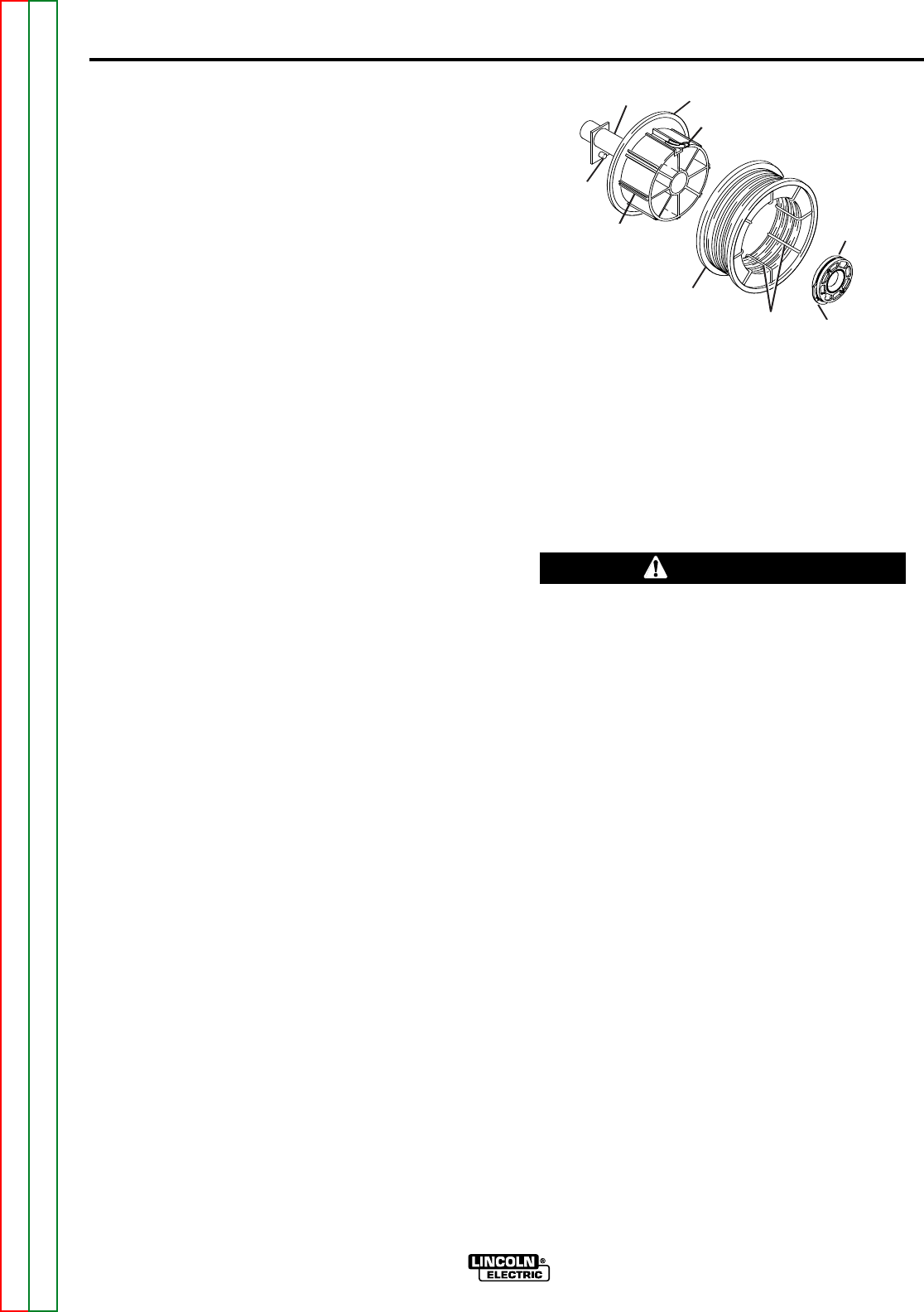

FIGURE B.2 — READI-REEL INSTALLATION.

8. Lower the Readi-Reel to depress the retaining

spring and align the other inside cage wires with

the grooves in the molded adapter.

9. Slide cage all the way onto the adapter until the

retaining spring “pops up” fully.

Check to be sure the retaining spring has fully returned

to the locking position and has securely locked the

Readi-Reel cage in place. The retaining spring must

rest on the cage, not on the welding

electrode.

------------------------------------------------------------------------

10. To remove Readi-Reel from adapter, depress

retaining spring tab with thumb while pulling the

Readi-Reel cage from the molded adapter with

both hands. Do not remove adapter from spindle.

To Mount 10 to 44 lb (4.5-20 kg) Spools

(12 in./300 mm Diameter) or 14 lb

(6 kg) Innershield Coils:

(For 13-14 lb (6 kg) innershield coils, a K435 coil

adapter must be used).

1. Open the wire drive compartment door.

2. Depress the release bar on the retaining collar

and remove it from the spindle.

3. Place the spool on the spindle making certain the

spindle brake pin enters one of the holes in the

back side of the spool (Note: an arrow mark on the

spindle lines up with the brake holding pin to

assist in lining up a hole). Be certain the wire

comes off the reel in a direction that it can de-reel

from the top of the coil.

4. Re-install the retaining collar. Make sure that the

release bar “pops up” and that the collar retainers

fully engage the retaining ring groove on the

spindle.

2 IN. O.D.

SPINDLE

ADAPTER

RETAINING

SPRING

BRAKE

HOLDING

PIN

GROOVES

READI-REEL

INSIDE

CAGE

WIRES

RELEASE

BAR

RETAINING

COLLAR

CAUTION