POWER MIG 255

TROUBLESHOOTING & REPAIR

F-42 F-42

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

6. Disconnect the wire connectors J13

and J12 to the motor/gearbox assem-

bly. See Wiring Diagram.

7. Use a 3/4 in. wrench and remove the

flange nut and positive lead from the

wire drive assembly. See Figure F.12.

8. Use pliers to remove the hose clamp

and flex hose from the wire drive

assembly.

9. Remove the outer guide assembly from

the wire drive assembly by loosening

the thumb screws until the outer guide

can be removed.

PROCEDURE

1. Disconnect main input power to the

machine.

2. Remove the wire gun and wire.

3. Lift the wire drive door to gain access to

the wire drive assembly.

4. Lift the tool tray door to allow access to

the tool tray.

5. Use a 5/16 in. nutdriver and remove the

tool tray to gain access to the

motor/gearbox assembly.

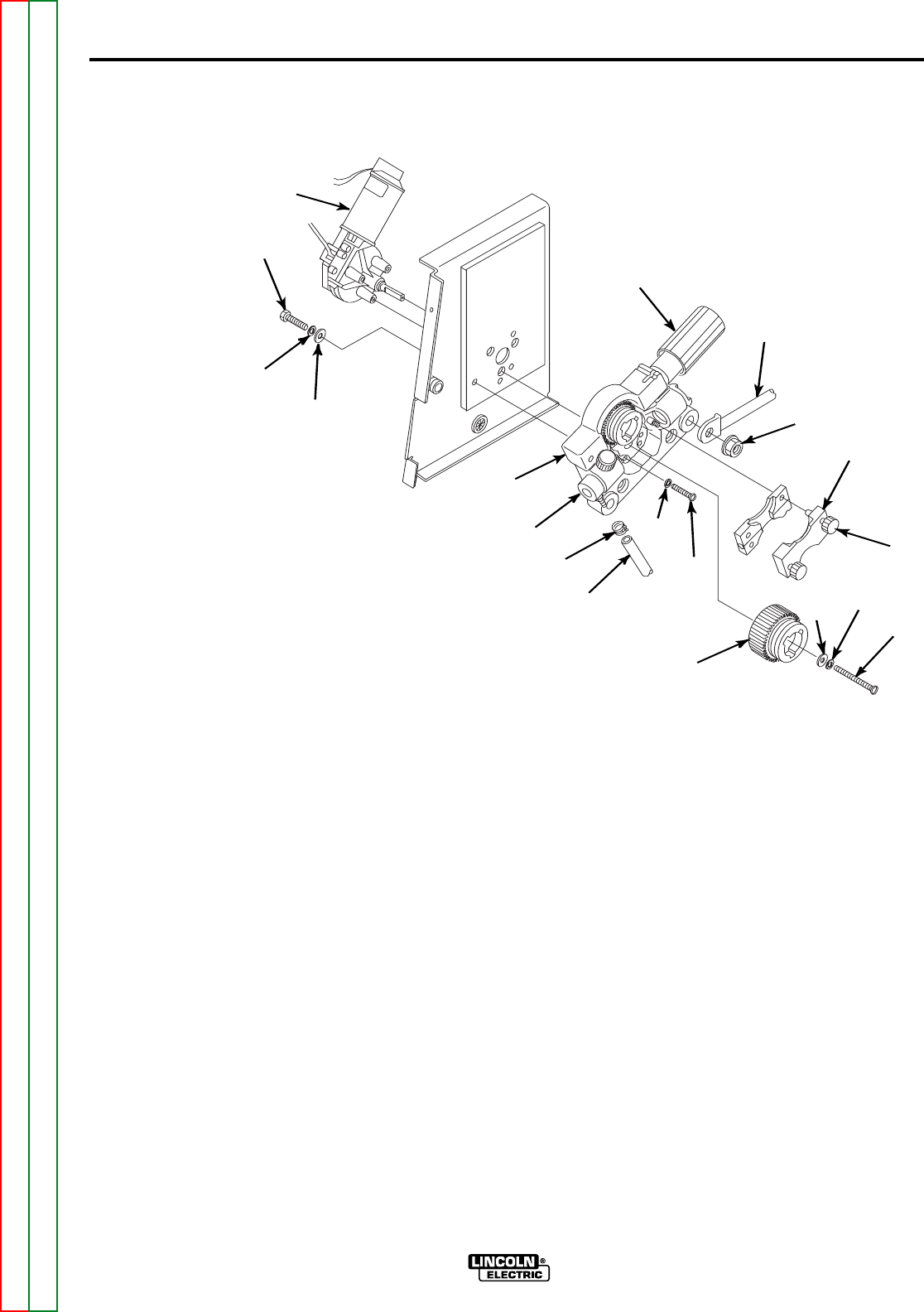

FIGURE F.12 — WIRE DRIVE ASSEMBLY REMOVAL FOR CODES 10563 & 10583 REFER TO P344-F.2

FOR EXPLODED VIEW OF WIRE DRIVE FOR CODES 10986 AND 10990 - SIMILAR PROCEDURE

4

3

7

8

14

13

12

11

2

17

18

19

9

10

1

5

6

16

15

WIRE DRIVE ASSEMBLY REMOVAL AND REPLACEMENT (continued)

1. Wire Drive Assembly

2. Motor/Gearbox Assembly

3. Flange Nut

4. Positive Lead

5. Hose Clamp

6. Flex Hose

7. Outer Guide Assembly

8. Thumb Screw

9. Adjustment Arm Assembly

10. Idle Arm

11. Round Head Screw

12. Lock Washer

13. Flat Washer

14. Molded Drive Roll Shaft

Assembly

15. Pan Head Screw

16. Lock Washer

17. Hex Head Cap Screw

18. Lock Washer

19. Flat Washer