POWER MIG 255

MAINTENANCE

D-4 D-4

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

CONTACT TIP AND GAS

NOZZLE INSTALLATION

1. Choose the correct size contact tip for the elec-

trode being used (wire size is stenciled on the side

of the contact tip) and screw it snugly into the gas

diffuser.

a. Be sure the nozzle insulator is fully screwed

onto the gun tube and does not block the gas

holes in the diffuser.

2. Slip or screw the appropriate gas nozzle onto the

nozzle insulator.

NOTE: Either a standard 0.50 in. (12.7 mm) or option-

al 0.62 in. (15.9 mm) I.D. slip-on gas nozzle may be

used and should be selected based on the welding

application.

3. Adjust the gas nozzle as appropriate for the

GMAW process to be used.

a. Typically, the contact tip end should be flush

to extended 0.12 in. (3.2 mm) for the short-

circuiting transfer process and recessed 0.12

in. (3.2 mm) for spray transfer.

LINER REMOVAL AND

REPLACEMENT

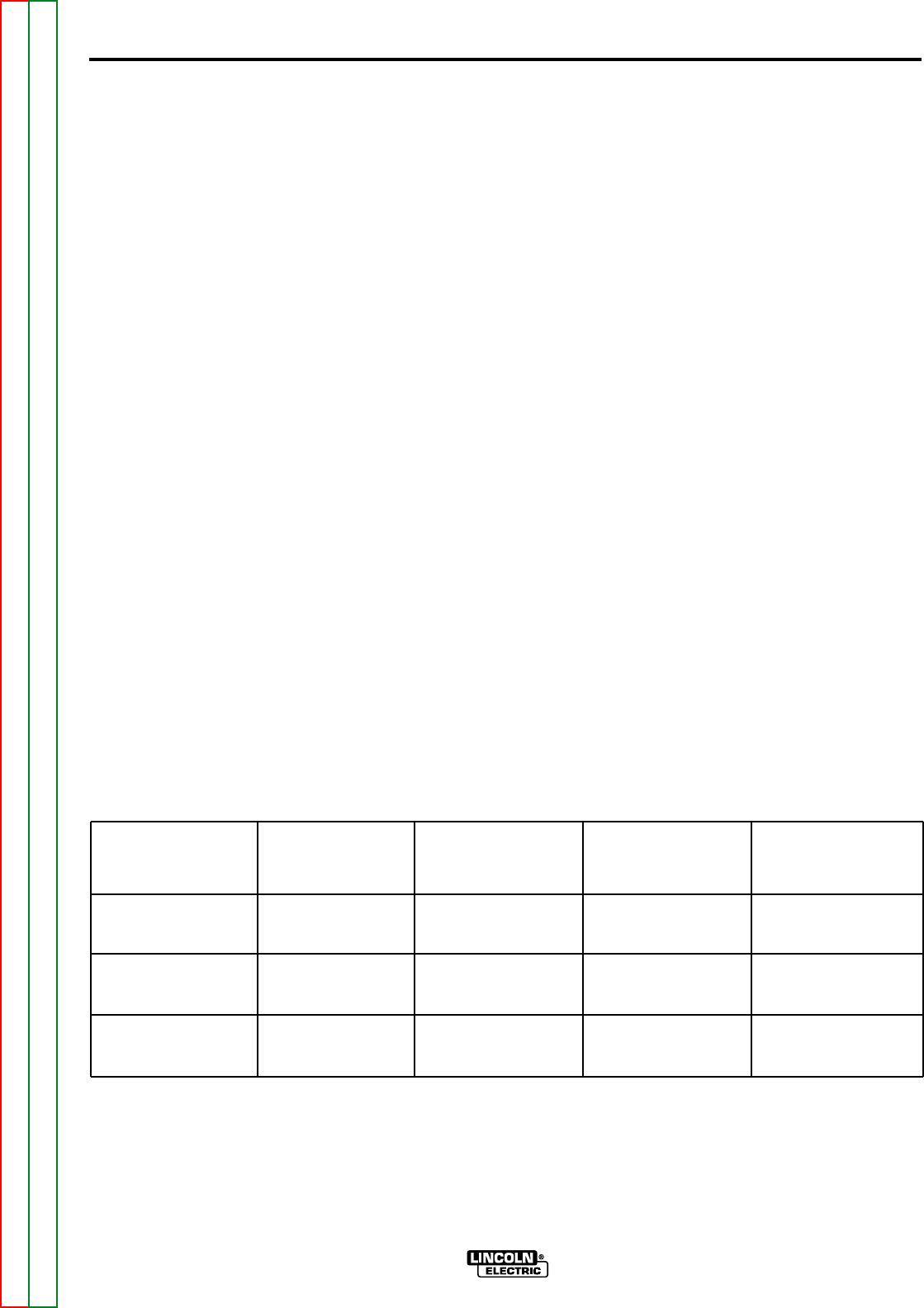

NOTE: When you change wire size, a replacement

gas diffuser is required. Use the table below to select

the proper diffuser so the liner is held securely in place.

LINER REMOVAL, INSTALLATION,

AND TRIMMING INSTRUCTIONS

FOR MAGNUM 250L

NOTE: The variation in cable lengths prevents the

interchangeability of liners between guns. Once a liner

has been cut for a particular gun, it should not be

installed in another gun unless it can meet the liner cut

off length requirement. Liners are shipped with the

jacket of the liner extended the proper amount.

1. Remove the gas nozzle and nozzle insulator. See

Figure D.2.

2. Locate the set screw in the gas diffuser which is

used to hold the old liner in place.

3. Loosen the set screw with a 5/64 in. (2.0 mm) Allen

wrench.

4. Remove the gas diffuser from the gun tube.

5. Lay the gun and cable out straight on a flat surface.

6. Loosen the set screw located in the brass cable

connector at the feeder end of the cable and pull

the liner out of the cable.

7. Insert a new untrimmed liner into the connector

end of the cable.

a. Check the liner bushing stencil to make sure

it is the appropriate one for the wire size being

used.

8. Fully seat the liner bushing into the connector.

Diameter of

Electrodes Used

0.025-0.030 in. Steel

(0.6-0.8 mm)

0.035-0.045 in. Steel

(0.9-1.2 mm)

3/64 in. Aluminum

(1.2 mm)

Replacement

Liner

Part Number

KP1934-2

KP1934-1

KP1955-1

Size Stenciled on

End of Liner

Bushing

0.030 in. (0.8 mm)

0.045 in. (1.2 mm)

3/64 in. (1.2 mm)

Fixed Nozzle Gas

Diffuser Part No.

(and Stencil)

KP2026-3

KP2026-3

KP2026-3

Adjustable Nozzle

Gas Diffuser Part

No. (and Stencil)

KP2026-2

KP2026-1B1

KP2026-1B1