-!(+2(()+-"('

%'S)+(

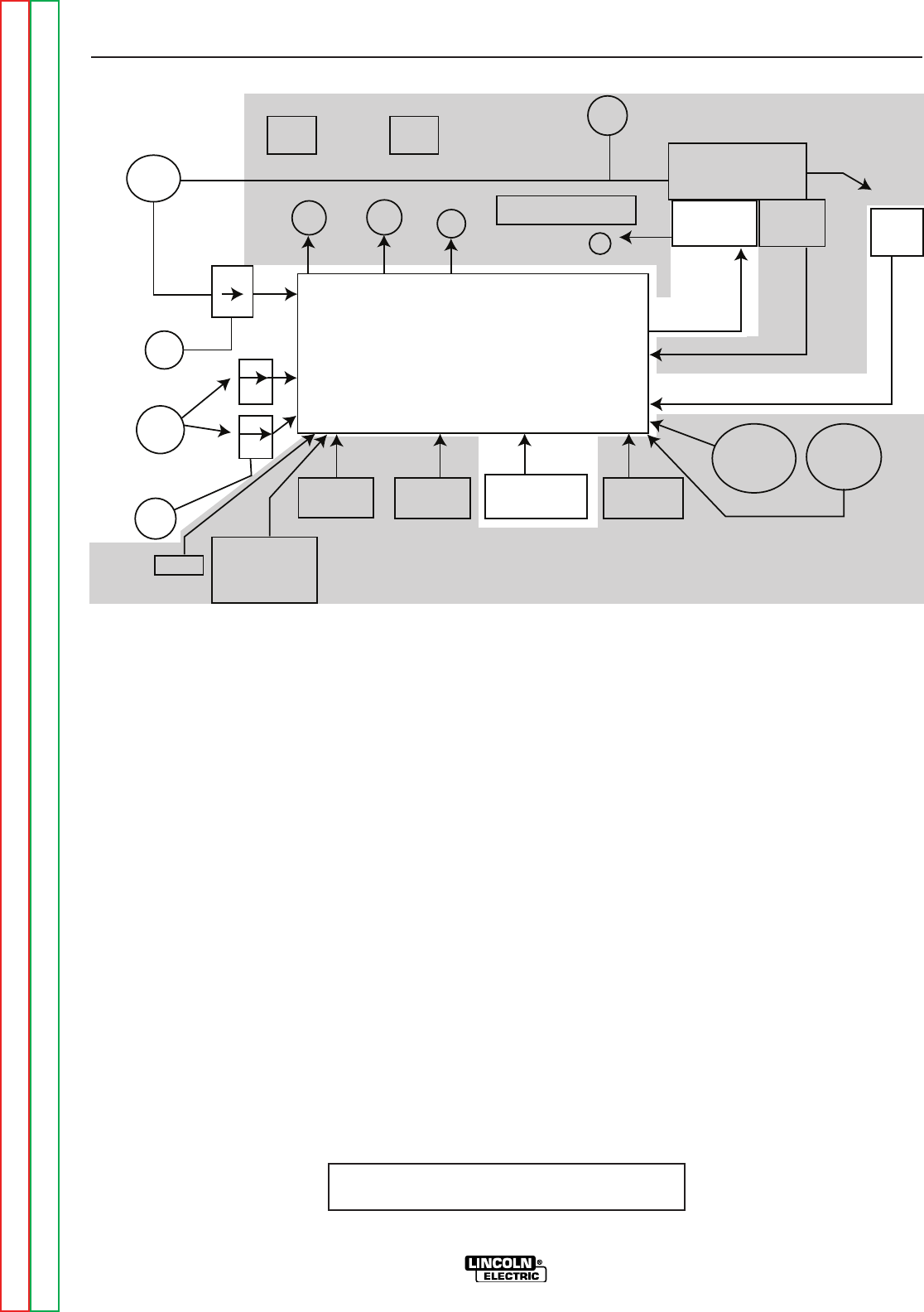

NOTE: Unshaded areas of Block Logic

Diagram are the subject of discussion

"').-)(0+

The DC input voltage is applied from the power source

via the electrode cable and the work sensing lead on

the across the arc model. With the control cable model

24 to 42VDC is supplied from the power source via the

control cable and the work sense lead.

This voltage is applied through a bridge rectifier and an

analog voltmeter (across the arc), or digital meter (con-

trol cable) and then is supplied to the control board.

The control board the regulates and disperses the var-

ious supply voltages needed for machine operation.

" .+W"').-)(0+-+" +"+."-

-+" +Z"+."-

When the gun trigger is closed, the control board is sig-

naled to apply armature voltage to the drive motor and

to activate any auxiliary circuits that may be incorpo-

rated within the LN-25PRO.

Trigger interlock is used for long welds. When an arc

is established the trigger can be released. To stop

welding, the gun trigger is pulled again, and when it is

released the second time, the welding power source

output turns off and the wire speed stops.

ELECTRODE

INPUT

CONTROL BOARD

FEEDPLATE

MOTOR

TACH

67

CONTACTOR

CURRENT TRANSDUCER

INPUT

SOLENOID

V M

POLARITY

TIMER OPTION

MOTOR

OVERLOAD

21

21

ARMATURE

TACH FEEDBACK

GUN TRIGGER

GUN

RUN IN

DIGITAL

DISPLAY

BOARD

COLD

FEED

CC

CV

TRIGGER

INTERLOCK

GAS

PURGE

WIRE

SPEED

REMOTE

VOLTAGE

14 PIN AMPHENOL

1

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC