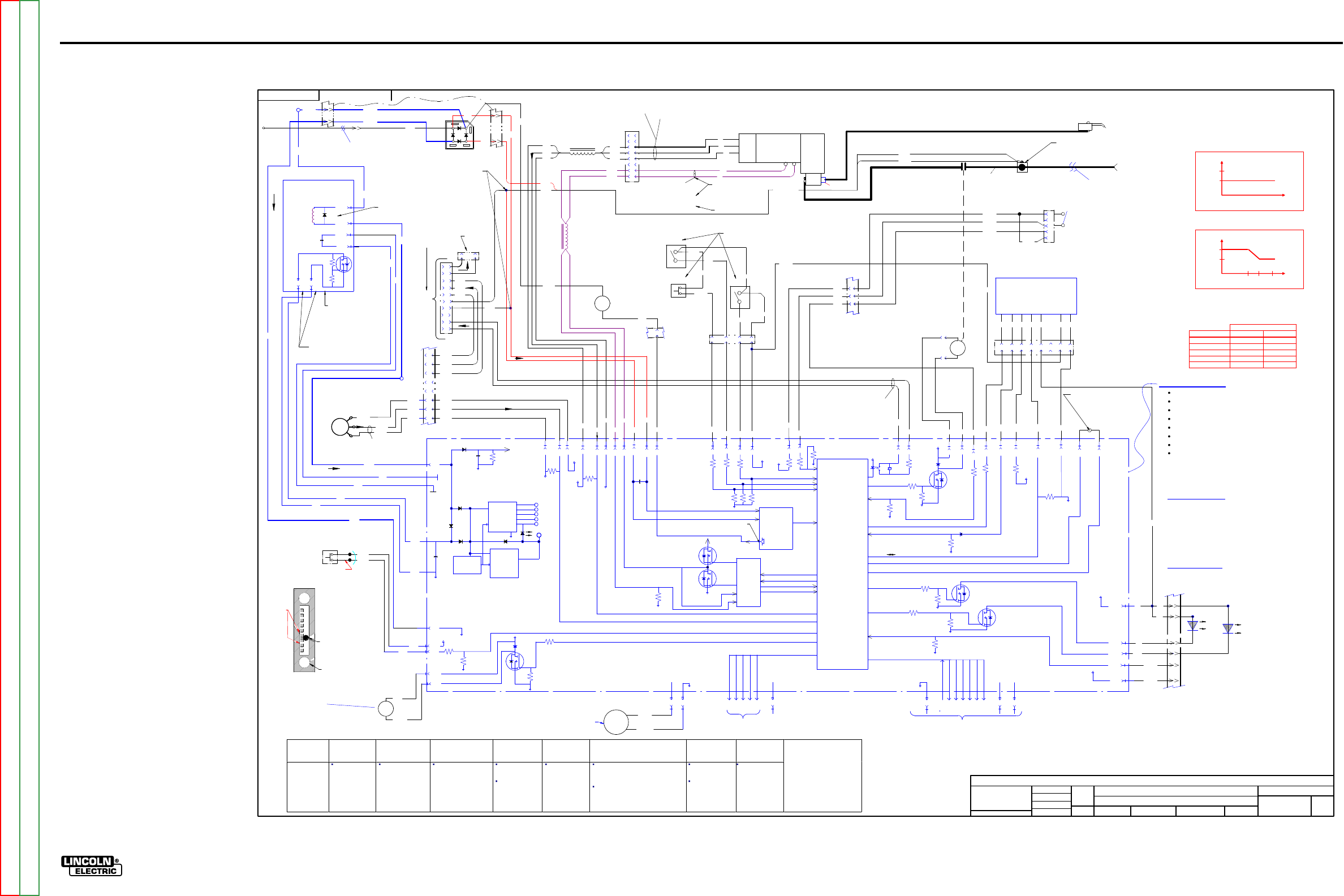

ElECTriCal DiaGrams

G-10

lN-25™ prO

sChEmaTiC - lN-25 prO - COmplETE maChiNE CODEs 11620, 11621, 11716, 11717 - (G5683-2) pG1

G568

3-

2

LN

-25 P

R

O A

N

ALOG

MAC

HI

N

E SC

HEM

ATIC

NONE

G5683-

1

DO NO

T

SC

AL

E

T

HIS DR

A

WING

EQ

UIP

M

ENT

TYPE:

SUBJECT:

SCA

L

E:

UF

CR

M40943

1

PAGE ___ OF

___

2

E

NGI

N

EE

RI

NG

CO

NT

RO

LLE

D

MA

NU

FA

CT

URE

R:

No

THIS DOCUMENT CONTAINS PROPRIETAR

Y

INFORMATION OWNED B

Y

LINCOLN GLOBA

L, INC.

AND MA

Y

NOT BE DUPLICATED, COMMUNICATED

TO O

THER PARTIES OR US

ED FOR

AN

Y

PURPOS

E WITHOU

T

THE EXPRES

S WRIT

TEN PERMISSION

OF LINCOLN GLOBAL, INC.

PRO

PRIETARY & C

ONFIDENTIAL:

t

MAT

ERI

A

L TO

L

ER

ANC

E ("

"

) TO A

GR

EE

WITH

PU

B

LI

SH

ED

ST

ANDARD

S.

ON A

LL

AN

GL

E

S I

S ± .5 OF

A D

E

GR

EE

ON

3

PLACE

D

E

CIM

ALS

IS

± .

00

2 i

n.

(

±

0.

0

5

mm)

ON 2

PL

AC

E D

ECIM

AL

S I

S ± .02 in. (

±

0.5 mm)

UNLESS OTHERWISE SPECIFIED TOLERANCE:

M

ANUF

ACTURING TO

L

ER

ANC

E

P

ER

E

2056

R

ELEASE

D A.03 F

ROM "

X

".

CHAN

GE

D

ET

AIL:

REFER

ENCE:

MA

T

ERI

AL

DIS

PO

SI

T

ION:

AP

PRO

VA

L

DA

T

E:

PROJ

EC

T

NUMBER:

DOCUMEN

T

NUMBER:

DOCUMEN

T

REV

ISI

ON:

IF PR

IN

T

ED

@ A

1

SIZ

E

UNI

T

S:

IN

CH

1

1/6/

2009

tpe

ar

n

ENYEDY

BS

DRAWN BY:

ENGINEER:

CLE

VE

L

AND

APPROVED:

CONTROL:

A

G5683-2

LN-25 PRO WIRE FEEDER

St

a

rt-Up

On power-

up,

the LN

-25 P

RO w

il

l

l

ight the

motor

thermal LE

D and

pol

ar

ity LE

D 2

-3 se

conds.

If the

feede

r i

s powered

-up with the trigge

r dep

re

ssed, weld

ing w

ill

not start un

ti

l the trigge

r i

s re

lea

sed and then depres

sed aga

in.

Note

s:

Motor over

cu

r

rent l

imit var

ie

s with WFS

.

FE

ED

PL

AT

E

67

C & 67

D

J4-10

1

4

3

2

6

5

P9

8

7

MOT

O

R /

GEARBOX

W

B

551

550

531

L4

537

534

72 H

Z TO 1.2 KHZ

R

-B 15.0 VD

C

B-

U 6.2 VD

C A

NY SPEED

(METE

R

D

EPE

NDE

NT

)

Mot

or i

s l

oc

ate

d

be

hi

nd

gl

ast

ic

pane

l

G

ear

bo

x rat

io

is

23.5:1

Motor c

ase i

s at

el

ectr

od

e pote

nti

al

From Power Sour

ce

(E

le

ctrode

C

onnect

ion

)

J4-7

0-5V PULSE SIGNAL

FREQUENC

Y

=

SPEED

WIRE FEED

SPEED

0V = MIN

SPEED

5V = MAX

SPEE

D

GAS PURGE

FLE

X

IBLE

PO

WE

R P.C. B

OA

RD

SCHE

MATIC

=

G4783

T

op

of

m

otor

Mot

or re

si

sta

nc

e

is

1.5

oh

ms

LeadsPassthrough

toroid 2times.

R

U

B

L

oc

at

e

d

on

C

as

e fro

nt

LeadsPass

through

toroid2times.

ISOLATED 2-4 TO

POWER SOU

RCE

BLACK

RED

FAN

+

-

S4

GAS PURGE

PUSHBUTTON

SWITCH

(

N.O

.)

61

2

61

0

13.5 VD

C W

HEN

NOT

D

EP

R

ESSE

D

J6-1

J6-7

J2-1

(LOCATED

I

NSI DE OF

CONTROL BOX)

FA

N BLOWS AIR AC

ROSS

CO

NT

RO

L PC BOA

R

D

CO

NTI

NO

U

SLY

AT

6200 RPMS.

GAS

SOLENOID

69

0

69

1

J4-4

J4-3

J2-5

100K

ohm

+15V

J3-7

+5

V

J

3

-

1

J

3

-2

J

3

-3

J3

-4

J

3-

5

PROGRAMMING

PCB

FACTORY USE ONLY

GAS SOLENOID

-

+

WORK

C

LI

P

+35V

POWER

SUPPL

Y

POWER

SUPPL

Y

+5V SPI

+15V SPI

OVER

VOL

TAGE

PROTECTION

ISO

LED

3

5VDC

+5VDC

+15V ISO

-15V

C

OM

MO

TOR

SUPPL

Y

C

OM

J5-1

J5-8

62

1A

Located onCase Front

J4-11

J4-12

J4-6

10

0K

o

hm

+5

V

J3-6

J3-8

+5

V

S

PI

J4-9

1

0K

o

hm

+15V

COM

534

537

531

J4-1

J4-2

550

551

TACH

FEEDB

ACK

Model

Ranger 8,9

Classic

Ranger 250,305

Commander300,400,500

(Common Analog

Controls)

V350

(Common Digital

Controls)

DC

-

400, 600

Square Wave TIG 300/355

MillerInverters

STTII

K

2613

-1

K2613-2

Recom mended

all CV

operation.

Recommended f or

CV operation.

(Wire F

eed

ModuleRequired)

Recommended for CV

operation.

Recommended

for CV

operation.

May be used for

pulsewelding if

the welding

procedure is

qualifiedby the

customer.

Recommended

forCV andCC

operation.

Notrecommendedfor CCoperation

because thecustomer may

experience short contactor life from

inductive nature of the power source.

Notrecommendedwithhighfrequency

TIG starting.

Recom mended

for CVv oltage

sense operat ion.

Not

recommended for

use whenpulse

welding.

Notrecommended

forSTToperation.

Note:

Most semiautomatic wire

welding processes perform

betterusingconstantvoltage

powersources. Besurethe

properpowersourceisused

for your application. Contactor

lifemaybeshortenedin

applicationsusing CC

machineswith highOCV.

J5-6

J5-7

21D

67F

721

J5-5

AN

ALO

G

VOLTMET

ER

667B

721

-

+

TRIGGER

-15

+15

72

1 IS DRIV

EN NEGATIVE TO COMPENSATE

FOR THE METER FOR D

IODE DROP

ERROR

ON THE BRIDGE

METER

COMPENSATION

CIRCUIT

POLARITY

SENSE

PROGRAM

BURNBAC

K

M

OTO

R

D

RI

VE

CI

RC

UI

T

MO

TOR VOL

TAGE

MO

TOR CURRENT

BRAKE

DRIVE

BRAKE

D

RI

VE

PW

M

0.05K

oh

m

L5

J6-3

J6-2

587

530

J6-4

523

J6

-6

509A

+15

V

COLD FEED

CC/VV

T

RI

GG

ER I

NT

ERLOC

K / 2 S

T

EP

S

1,

S

2

& S

3 L

oc

ate

d

on Wir

e

D

riv

e

P

an

el

CC

509D

CV

509E

TRI

GGE

R I

NT

E

RL

OCK

(N

OT

PRESE

NT

O

N

K2613-3)

S1

587

2-ST

EP

Lo

cat

ed

on Wir

e

D

riv

e

P

an

el

T

rig

ger I

nter

lo

ck

do

es

not

sto

p

w

eldi

ng

w

he

n th

e ar

c i

s br

ok

en.

P

ul

l a

nd r

el

ea

se t

o e

nd t

he

w

el

d.

509B

S2

523

S3

C

OL

D F

EED

530A

509E

(LOCATED

A

T

REAR

O

F

FEEDER)

66

7C

0V=

CO

L

D FEE

D

(

N.O.)

15V=

CV

0V=

CC

15V=

2 STEP

0V=T

RIGGE

R

INTE

R

LO

CK

4B

606A

2

4

+15V

J

5-4

J5-3

MOV

MACHINE

OUTPU

T

ENABLE

CONTAC

TOR DRIVE

COM

+35V

J4-

8

J4-5

CO

NT

A

CT

OR

4

O COIL

0

VDC

OPEN

3

VDC CLOSED

12 VDC COIL

PWM

CO

NTROLLED

507

578

20

ohm

0V = OF

F

2

0msec ----

25

0msec

605

601

J2-6

J2-3

608

607

J2-7

COM

Y

ELLO

W

THERMAL

LED

COM

POLARITY LED

J6-11

1W

J6-14

B

+5V SPI

GREEN

POLARITY

LED

Y

ELL

OW

MOT

OR

TH

E

RM

AL

LE

D

ARC ESTABLISHED

J1-2

J1

-1

+5V SPI

+15V

J1-10

J

1

-8

J

1

-6

J

1-5

J1

-4

J

1

-9

J

1

-3

J

1

-7

S

C

L

K

C

S

3

C

S

2

C

S

1

C

S

0

M

O

S

I

M

IS

O

SPI

DIGITA

lL COMMUNICATION

J6-8

-15V

GAS

ON - OF

F

GAS

FLOW

ENABLE

Lo

cat

ed

un

der

Wire

D

riv

e

P

an

el

(LOCATED

A

T

OUT

SI

DE

REAR

O

F

FEEDER)

10K/2W

0 VD

C MI

N. WFS

5 VD

C MA

X

.

WFS

WI

R

E F

EE

D

SPEED

CO

NT

R

OL

P

OT

E

NTIOM

ET

ER

62

1

66

7

11

10

P7

12

Conn

ect

or

l

oc

at

ed

behin

d c

as

e fro

nt

COM

15

14

(LOCATED

A

T

TOP

FRON

T

O

F

FEEDER)

MICRO

CONTROLLER

COM

MO

TOR

SUPPL

Y

6

8

7

5

1

3

4

6

2

8

7

9

10

J18

1

P16

L

oc

at

e

d

on

top

of m

ot

or

PLASTIC

HO

U

SE

D BOLTE

D

CO

NNE

CTIO

N

(BASE

CE

NTE

R)

TIMER KIT

P.C. B

OA

RD

(

OPTIO

NAL

)

SCHE

MATIC

=

M213

41

SEE

PAGE 2

L12081 2.6 V

@ 50

IPM

27

V @

700

IPM

L13084 2.6 V

@ 25

IPM

32

V @

400

IPM

0V

.=

TR

IG

GER

CLOSED

15

VDC

.=

TR

IG

GER

OPEN

Lo

cat

ed

on

C

as

e

F

ront

TRI

GGER

IN

P

UT

TRI

GGE

R

CONNE

CT

OR

J14

622A

500A

E

B

C

D

A

P7-1

67D

67C

66

7B

67

B

4

1

3

6

67C

67B

IN

HARN

ESS

CE

NTE

R BASE

AR

EA

P

7

=

16

PI

N

P

17

=

6

PI

N (

B

oth

are

lo

cat

ed on

lo

w

er fr

ont)

57

7A

57

6A

57

5A

57

7A

57

5A

57

6A

57

7A

57

6A

57

5A

77

C

76

C

75

C

531

537

534

40V MA

X.

21

B

.05

uF

60

0 V

70

7

608

607

J2-8

4B

gun connecto

r

4 of 4

3 of 4

J6-9

J6-10

622

500

+15

V

2 of 2

P

17

P7

1 of 4

P7

When tach feed back is

lo

st,

the voltage to

the

motor is a

constant 10VD

C.

(c

ontro

l

led b

y so

ftware

)

P

17

ca

se

fron

t

str

ain

rel

ief

1 of 2

5

2 of 4

coppe

r

bar

coppe

r

bar

weld cable

13

2B

1B

R1

D1

ca

se

ba

ck

str

ain

rel

ief

509C

21

A

21

C

21E

JU

MPE

R TOGET

HE

R FO

R

EX

TRA TO

RQ

U

E MAC

HI

NE

P6

0

3

4

5

67

8

601

509B

605

2

1

3

4

2

J2-2

+5V

606

EX

TRA TO

RQ

UE

TAKEN WITH 40 V INP

UT

IN

C

V MODE.

66

7A

WFSlimitedbyarcvoltagewhenoperatingacrossthearc

Feeder Input Volts Standard Gear Extra Torque

15

280

210

17

340

235

21

440

400

24

520

400

27

600

400

Maximum WFS

EXTRA

TO

RQUE

Control

Boar d Summary

Converts arc power to a usable control circ uit voltage.

Recei ves switch signals from Trigger, Cold Feed, Gas Pur ge

Reads WFS potentiometer.

Communicates with optional timer ki t.

Controls motor speed with PW M.

Turns Gas Solenoid on, off

, PWM

.

Reads the motor tachometer.

O

perat

ing V

o

ltage=

15

-

110 VD

C.

Shut down

Voltage

=130

VDC

.

Thermal light turns on when shutdown voltage exceeded.

Code and Serial numbers are below Wire Drive on plastic

housing Nameplate.

Thermal “Yellow” Light

Moto r O

ver

Current

Motor and trigger disabled for30 seconds.

Must retrigger to start weldingafter 30 seconds pass.

Shutdown Voltage exceeded

May occur with someinverters.

May occur with some CC machines with high

inductance.

Polarity “Green” Light

On=

Positive Polarity

Off=Negative Polarity

70

8J6-5

9

2W

J6-12

16

509B

The WFS range of the LN-

25 PRO

No

rmal Speed

= 40

- 700 IPM.

E

x

tra Torque

= 25

- 400 IPM.

Before 2-20-2009

After 2-20-2009

*Extra Torque

370 530 700

180* 257* 400*

3.5

4.5

3.5

4.5

Preset

WFS

Current

Level

Current

Level

Preset

WFS

77

C

76

C

75

C

61

0

61

2

B1

B2

C2

C1

C1

C2

B1

B2

66

7D

66

7E

B2

B1

62

1

66

7D

25

TO 35

NOR

MAL

FL

OW

RATE

GOOD FO

R A

r, CO2,

CO

2/Ar BLEN

DS

(O

UTSIDE

BACK

O

F

CASE)

FL

OW

METER

22 O COIL

0

VDC

OPEN

4 VDC CLOSED

12 VDC COIL

PWM

CO

NTROLLED

BALL FLOAT

U

SE MID

D

LE

OF BALL TO

SET

AD

J

UST VALVE

NOT P

R

ESE

NT

ON S2750

5

J6

1-

1

J6

1-

3

J6

1-

4

J6

1-

2

J6

2-

2

J6

2-

1

MOTO

R

FI

LTE

R

P.

C.

BOAR

D

SCH

EM

A

TI

C=

S2

75

92 B

EFOR

E 6/15/2

00

9

S2

75

05 A

FTE

R

6/15/2

00

9

U

SE

D TO

DIS

CHA

RGE

POWER S

U

PPLY

CAP

AFTE

R A

HIG

H VOLTAGE

TRA

N

SIENT. LATER

R

ELO

C

ATED TO THE

CO

NT

RO

L BOAR

D.

U

SE

D FO

R FILTE

RI

NG

INVE

RTE

R

NOISE

J1

5

14 PIN

R

EMOTE

LEA

D

S ARE

PR

ESE

NT B

UT

NOT

U

SE

D I

N

THIS

U

NIT.

NOT

U

SE

D

J2-10

555

622

500

4

2

555

3

555A

622B

G-10

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC