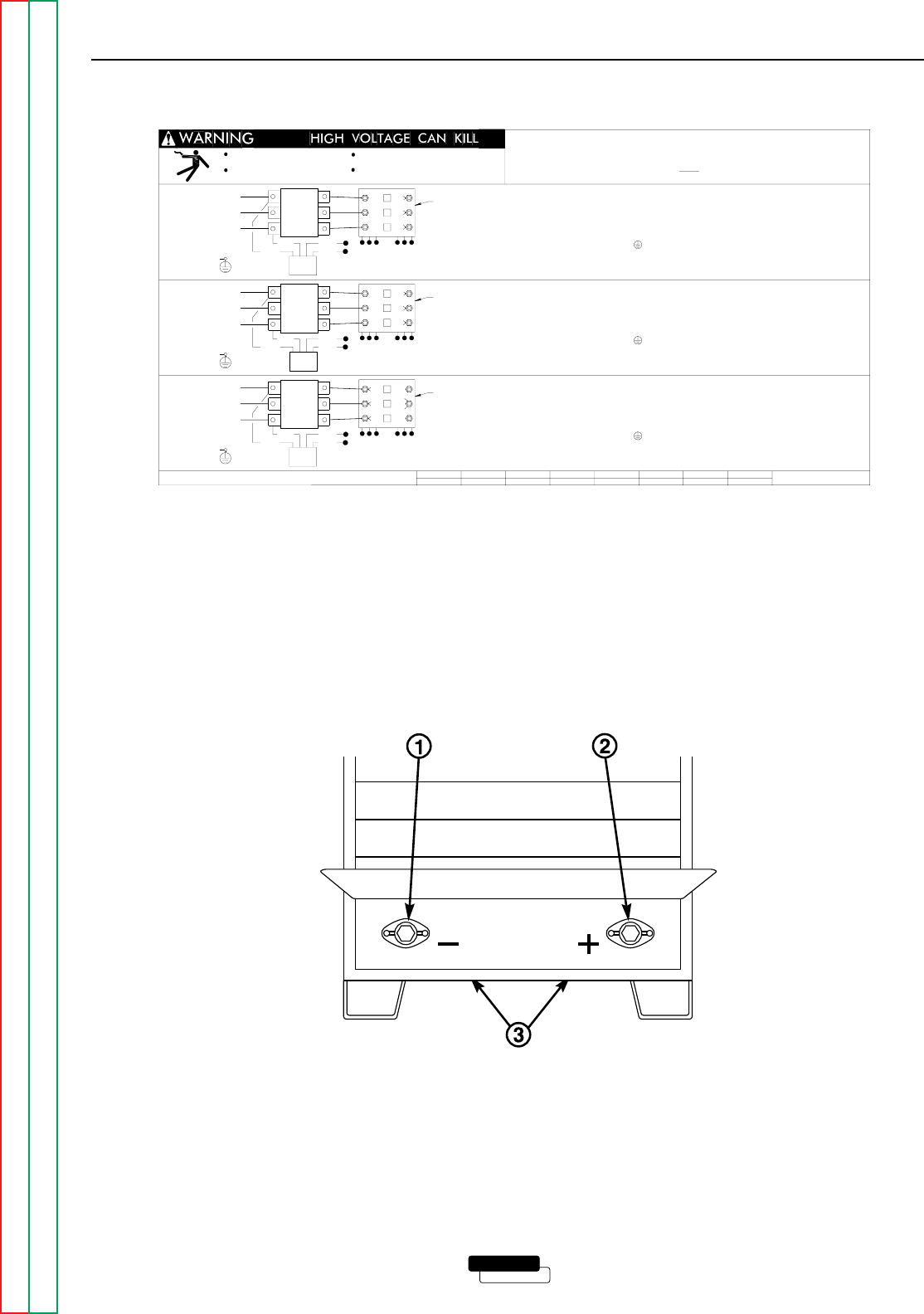

OUTPUT CONNECTIONS

The output (welding) cables are connected to the output

terminals marked “+” and “-”. See Table A.1 for recom-

mended cable sizes for the combined lengths of elec-

trode and work cables. They are located at the lower

right and lower left corners of the front panel. Strain

relief for the cables is provided by routing them through

the rectangular holes in the base before connecting

them to the output terminals. Lift the output terminal

cover to access the output terminals. Lower the cover

after making the connections. See Figure A.6.

INSTALLATION

A-7 A-7

LINCOLN

®

ELECTRIC

IDEALARC DC-400

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

FIGURE A.5 - INPUT CONNECTION DIAGRAM FOR 230/460/575 VOLTS AC, 60 HZ

THE LINCOLN ELECTRIC CO., CLEVELAND OHIO U.S.A.

M15666

INPUT SUPPLY CONNECTION DIAGRAM

H3

GND

H2

Do not touch electrically live parts

Only qualified persons should install,

use or service this equipment

removed

servicing

Do not operate with covers

Disconnect input power before

INPUT

LINES

L1

H1

L2

L3

{

CR1

V

U

W

CONTACTOR

H4

PILOT

TRANSF.

1. CONNECT L1, L2 & L3 INPUT SUPPLY LINES AND H1 & H4 PILOT

TRANSFORMER LEADS TO THE INPUT SIDE OF CR1 CONTACTOR AS SHOWN.

2. INSULATE UNUSED H2, H3 LEAD TERMINALS SEPERATELY TO PROVIDE

AT LEAST 600V INSULATION.

4. CONNECT TRANSFORMER LEADS 16, 17, 18, 4 & 13, 5 & 14, 6 & 15 TO RECONNECT PANEL.

5. TAPE SEPERATELY TO PROVIDE AT LEAST 600V INSULATION 1, 2, 3, 7, 8, 9.

TAPE INSULATED UNUSED LEADS TOGETHER AWAY FROM LIVE METAL PARTS.

IDEALARC (230 / 460 / 575)

NOTE: MACHINES ARE SHIPPED FROM FACTORY CONNECTED FOR 575V

CONNECTION FOR 575 VOLTS, 60 HZ.

3. CONNECT TERMINAL MARKED TO SYSTEM GROUND PER NATIONAL ELECTRIC CODES.

1. CONNECT L1, L2 & L3 INPUT SUPPLY LINES AND H1 & H3 PILOT

TRANSFORMER LEADS TO THE INPUT SIDE OF CR1 CONTACTOR AS SHOWN.

2. INSULATE UNUSED H2, H4 LEAD TERMINALS SEPERATELY TO PROVIDE

AT LEAST 600V INSULATION.

CONNECTION FOR 460 VOLTS, 60 HZ.

3. CONNECT TERMINAL MARKED TO SYSTEM GROUND PER NATIONAL ELECTRIC CODES.

1. CONNECT L1, L2 & L3 INPUT SUPPLY LINES AND H1 & H2 PILOT

TRANSFORMER LEADS TO THE INPUT SIDE OF CR1 CONTACTOR AS SHOWN.

2. INSULATE UNUSED H3, H4 LEAD TERMINALS SEPERATELY TO PROVIDE

AT LEAST 600V INSULATION.

CONNECTION FOR 230 VOLTS, 60 HZ.

3. CONNECT TERMINAL MARKED TO SYSTEM GROUND PER NATIONAL ELECTRIC CODES.

RECONNECT

PANEL

4. CONNECT TRANSFORMER LEADS 1, 2, 3, 4 & 7, 5 & 8, 6 & 9 TO RECONNECT PANEL.

5. TAPE SEPERATELY TO PROVIDE AT LEAST 600V INSULATION 13, 14, 15, 16, 17, 18.

TAPE INSULATED UNUSED LEADS TOGETHER AWAY FROM LIVE METAL PARTS.

4. CONNECT TRANSFORMER LEADS 1 & 7, 2 & 8, 3 & 9, 4 & 5 & 6, TO RECONNECT PANEL.

5. TAPE SEPERATELY TO PROVIDE AT LEAST 600V INSULATION 13, 14, 15, 16, 17, 18.

TAPE INSULATED UNUSED LEADS TOGETHER AWAY FROM LIVE METAL PARTS.

18

17

16

6

15

5

14

4

13

9

8

7

32

1

H4

GND

H2

INPUT

LINES

L1

H1

L2

L3

{

CR1

V

U

W

CONTACTOR

H3

PILOT

TRANSF.

RECONNECT

PANEL

3

2

1

6

9

5

8

4

7

15

14

13

1817

16

H4

GND

H3

INPUT

LINES

L1

H1

L2

L3

{

CR1

V

U

W

CONTACTOR

H2

PILOT

TRANSF.

RECONNECT

PANEL

6

5

4

9

3

8

2

7

1

15

14

13

1817

16

IMPORTANT: CHANGE LINK POSITIONS AND PILOT TRANSFORMER CONNECTIONS

.

5-26-95

FIGURE A.6 - OUTPUT TERMINAL CONNECTIONS

1. NEGATIVE (-) WELDING CABLE CONNECTION

2. POSITIVE (+) WELDING CABLE CONNECTION

3. CABLE STRAIN RELIEF HOLE LOCATION