Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

ACCESSORIES

C-9 C-9

LINCOLN

®

ELECTRIC

IDEALARC DC-400

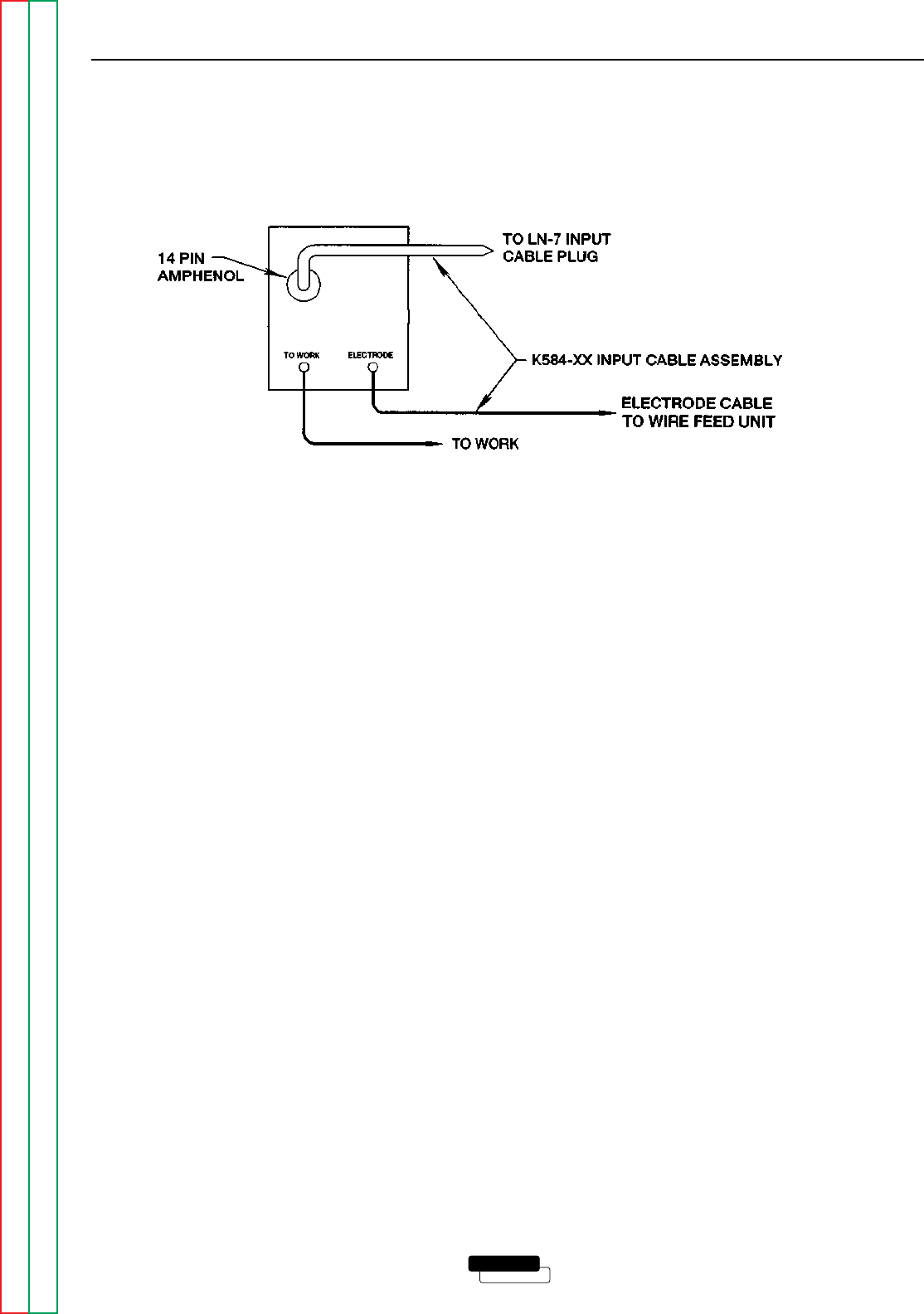

FIGURE C.7

IDEALARC DC-400/LN-7 WITH K584 INPUT CABLE ASSEMBLY CONNECTION DIAGRAM

SEMIAUTOMATIC WIRE FEEDERS

CONNECTING THE LN-7 TO THE IDEALARC

DC-400 (14-PIN AMPHENOL)

1. Disconnect main AC input power to the Idealarc

DC-400.

2. Set the POWER toggle switch to the OFF (0) posi-

tion.

3. Connect the electrode cable from the K584-XX

Input Cable Assembly to the “+” terminal of the

welder and to the LN-7 wire feeder. Connect the

work cable to the “-” terminal of the welder.

Reverse this hookup for negative polarity.

NOTE: Welding cable must be sized for the current

and duty cycle of the application.

4. Connect K584-XX Input Cable between the DC-

400 and the LN-7. See Figure C.7.

5. Set the welder VOLTMETER toggle switch to the

desired polarity, either DC (-) or DC (+).

6. Set the MODE switch to a CV (constant voltage)

position at the welder.

7. Adjust wire feed speed at the LN-7 and set the

welding voltage with the OUTPUT CONTROL.

NOTE: If optional remote control is used, place the

OUTPUT CONTROL and the OUTPUT TERMI-

NALS switch in the “Remote” position.