Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

INSTALLATION

A-8 A-8

LINCOLN

®

ELECTRIC

IDEALARC DC-400

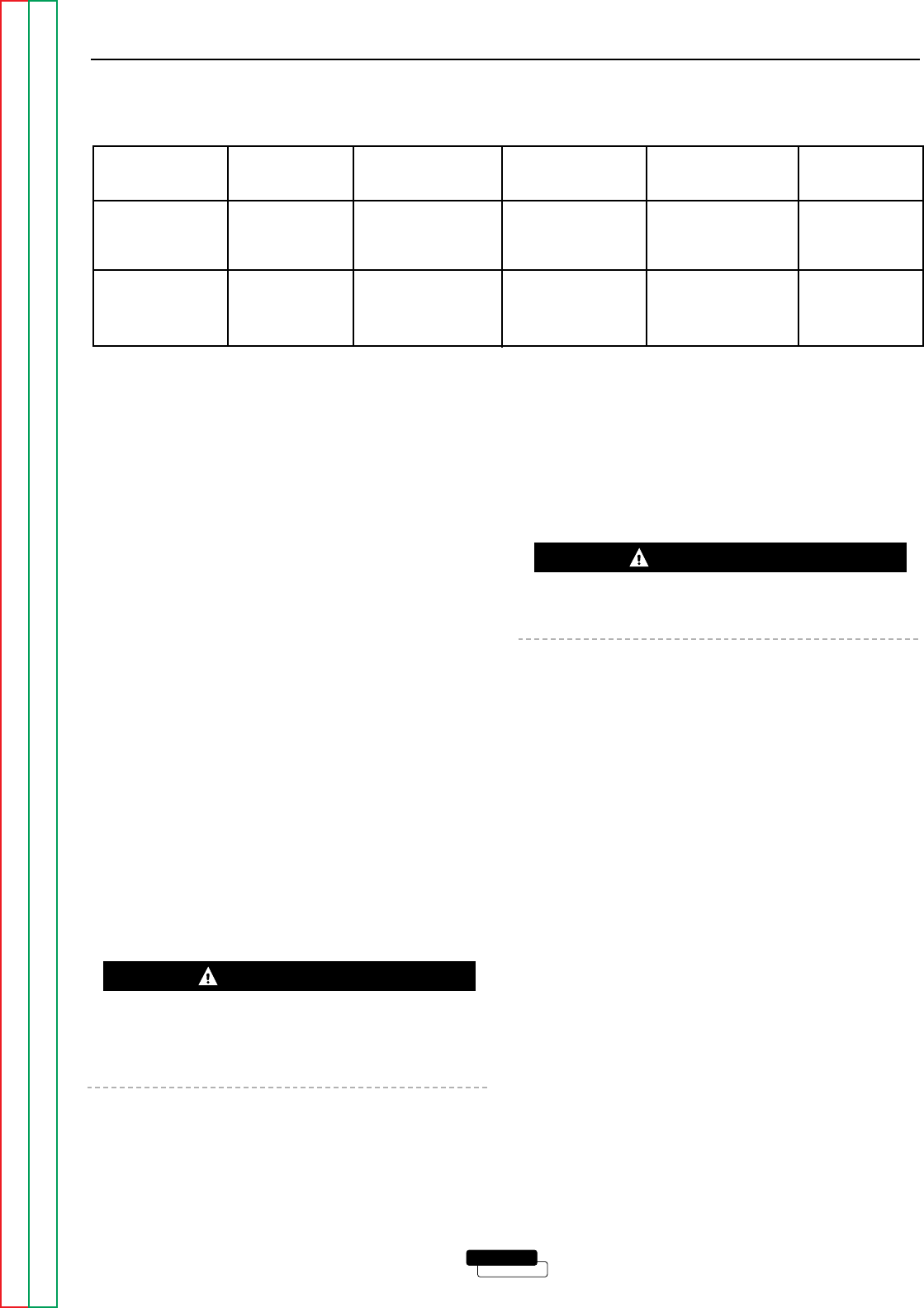

TABLE A.1 - CABLE SIZES FOR COMBINED LENGTHS OF COPPER ELECTRODE

AND WORK CABLES

Up to 50 ft 50 - 100 ft 100 - 150 ft 150 - 200 ft 200 - 250 ft

Machine Size (15 m) (15 - 30 m) (30 - 46 m) (46 - 61 m) (67 - 76 m)

400 Amp 3/0 3/0 3/0 3/0 4/0

(100% Duty 85 mm

2

85 mm

2

85 mm

2

85 mm

2

107 mm

2

Cycle)

500 Amp 2/0 2/0 3/0 3/0 4/0

(50% Duty 67 mm

2

67 mm

2

85 mm

2

85 mm

2

107 mm

2

Cycle)

WIRE FEEDER CONNECTIONS

See the Accessories section of this manual for spe-

cific instructions on connecting the following semi-

automatic and automatic wire feeders to the Idealarc

DC-400:

Automatic Wire Feeders:

• NA-3

• NA-5

Semi-automatic Wire Feeders:

• LN-7

• LN-8

• LN-9

• LN-25

• LN-742

CONNECTIONS FOR STICK, TIG, OR

AIR/CARBON ARC CUTTING OPERA-

TIONS

The output terminals are energized at all times when

the Idealarc DC-400 is used for stick, TIG, or air/car-

bon arc cutting.

The work and electrode cables for stick, TIG, or

air/carbon arc cutting are connected as described ear-

lier, under the heading Output Connections. A TIG

torch is connected to the electrode (+) terminal of the

welder. Select cable size according to Table A.1.

Do not connect a TIG torch and stick electrode cable

at the same time. They will both be electrically HOT.

If the Idealarc DC-400 is already set up for wire feeder

operation, all wire feeder unit control, electrode, and

work cables must be disconnected first before you

can connect the cables for stick, TIG, or air/carbon arc

operation.

However, the Idealarc DC-400 can be used for both

wire feeder operation and stick, TIG, air/carbon arc

operation if a K804-1 Multiprocess Switch is used.

See the Accessories section of this manual for spe-

cific instructions on connecting and using the

Multiprocess Switch.

WARNING

WARNING

96OCT